Lithium battery accurate recovery method and device

A recycling method, lithium battery technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problem of inaccurate and efficient distinction of recycling effects, and achieve convenience for subsequent utilization and treatment, less impurities, and overcome the use of a large number of solvents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for accurately recycling lithium batteries, comprising the following steps:

[0050] Step 1, the waste lithium battery is discharged;

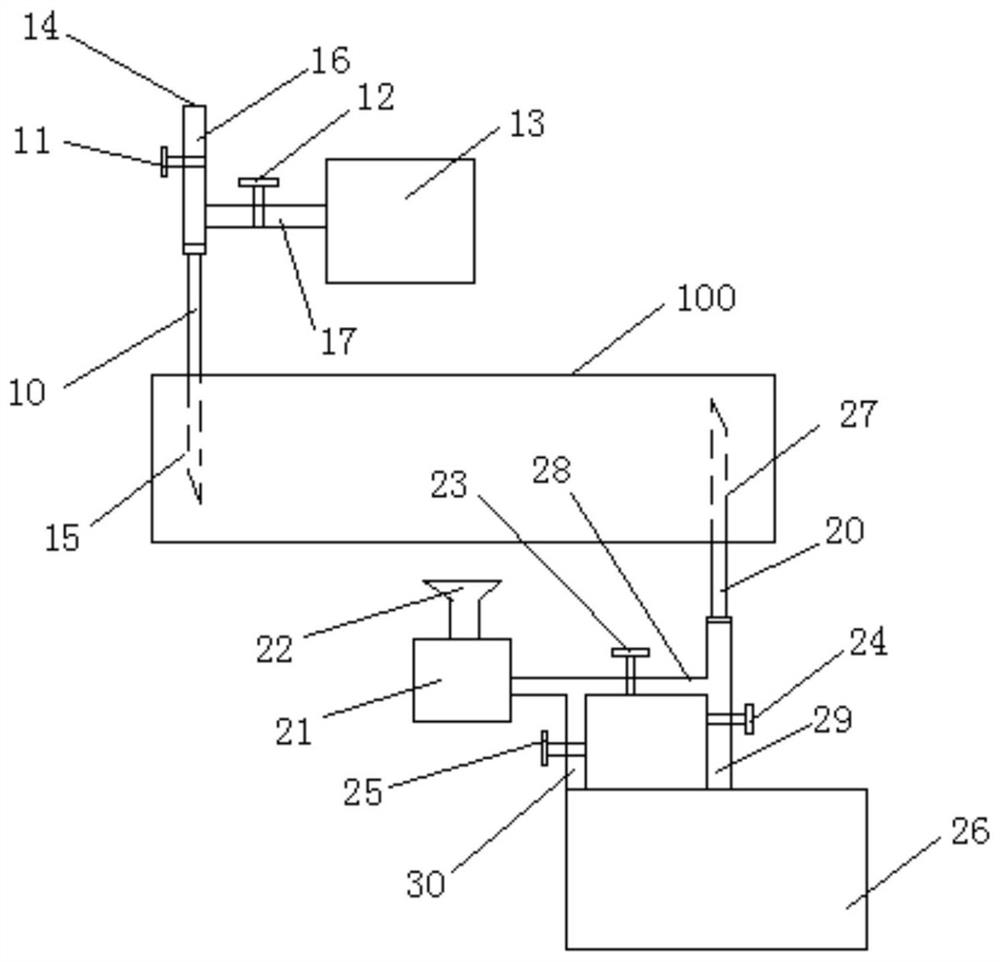

[0051] Step 2, using a waste lithium battery electrolyte recovery device to pump the electrolyte inside the waste lithium battery into the first collection box 26, and dry the inside and outside of the waste lithium battery from which the electrolyte has been removed;

[0052] Step 3: Cut and separate the shell of the waste lithium battery, recycle the shell and obtain the battery pole core;

[0053] Step 4, cutting and pulverizing the battery pole core to obtain battery pole core pulverization;

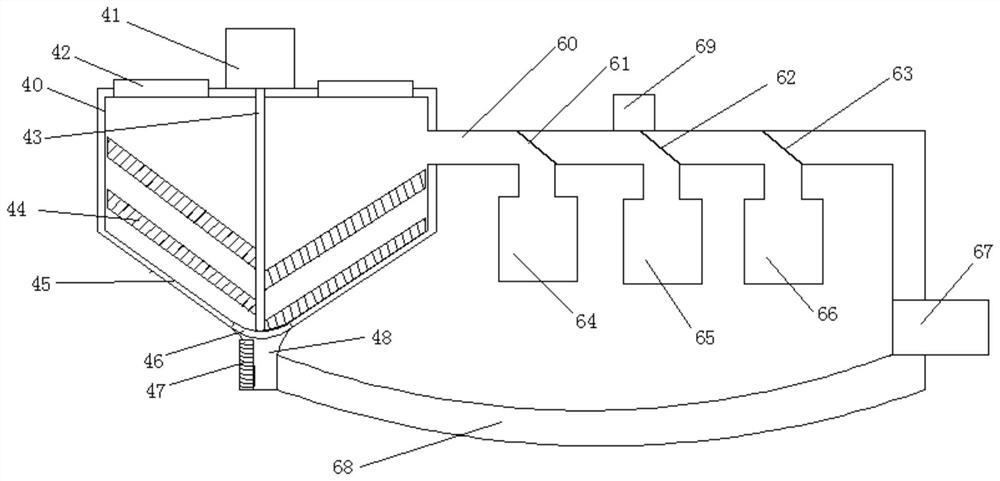

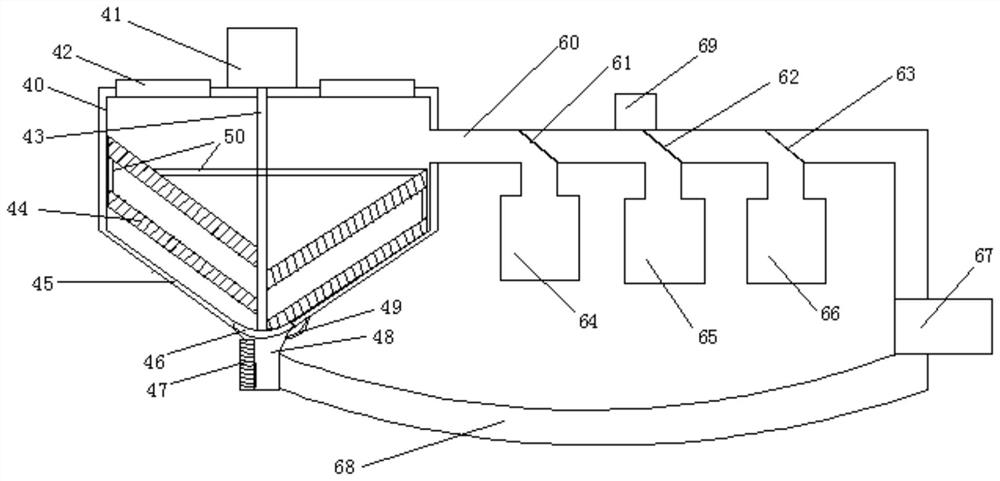

[0054] Step 5. Place the crushed battery pole core figure 2 In the pulverizer 40 of the graphite separation device, the graphite in the pulverizer of the battery pole core is pulverized, and dust is pulverized in the pulverizer 40, air is sprayed at the bottom of the pulverizer 40, and powder is sucked on the upper side wall or top...

Embodiment 2

[0056] A method for accurately recycling lithium batteries, comprising the following steps:

[0057] Step 1, the waste lithium battery is discharged;

[0058] Step 2, using such as figure 1 The waste lithium battery electrolyte recovery device, clamping the waste lithium battery 100 in a flat position or a vertical position, dislocation above and below the waste lithium battery to insert a needle into the inner cavity of the waste lithium battery, and a plurality of through holes are distributed on the top of the needle , the first needle 10 can be selectively communicated with the external air or the drying fan 13, and the second needle 20 can be selectively communicated with the first collection box 26 or the external air; Suction into the first collection box 26, after suction, fill the cavity of the waste lithium battery with dry gas through the first needle 10, and the second needle 20 will extract the gas in the cavity of the waste lithium battery, and spray it to the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com