An all-in-one self-driving all-textile gesture recognition data glove

A gesture recognition and data glove technology, applied in the field of human-computer interaction, can solve the problems of complex stitching of sensor devices, weak sensitivity and stability, and bulky data glove energy supply equipment, and achieve simplified circuits, improved structural appearance, and environmentally friendly power supply methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

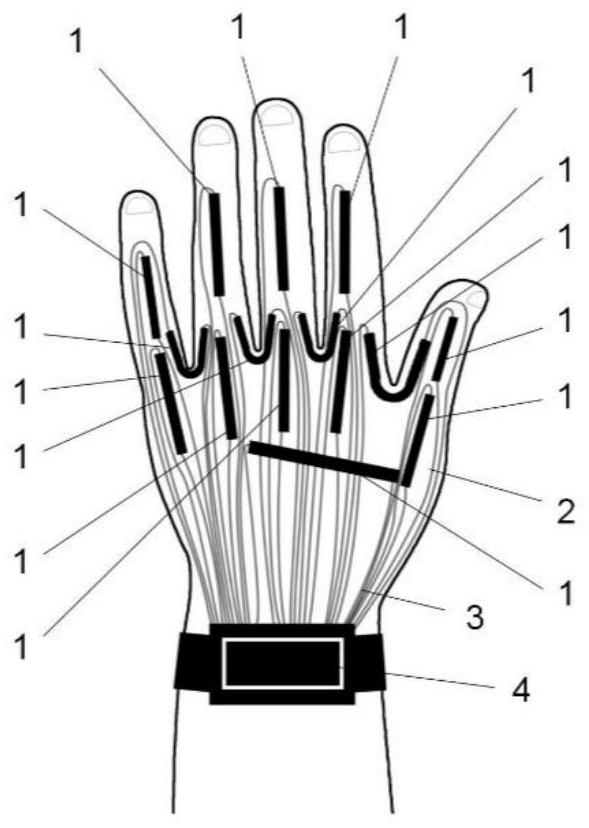

[0050] like Figure 4 As shown, the data glove shown in the present invention includes a glove base 2, a self-powered strain sensing yarn 7, a flexible and weakly sensitive conductive yarn 8, and a control circuit 4; wherein, the glove base 2 is woven with elastic insulating yarn through a knitting process , the fabric can be plain weave (such as Image 6 shown) for a snug glove-to-hand fit and as a stand to support the entire sensing circuit. The specific elastic insulating yarn adopts nylon yarn; the self-powered strain sensing part has a total of 20 different positions, and the self-powered strain sensing yarn 7 is used for plating (such as Figure 7 Shown) are respectively set on the distal interphalangeal joint 9 (DIP joint: first phalanx joint), proximal interphalangeal joint 10 (PIP joint: second phalangeal joint) and metacarpophalangeal joint 11 of the little finger, ring finger, middle finger, and index finger (MP joint: third phalangeal joint) and the distal interp...

Embodiment 2

[0056] The present invention also provides an embodiment, because in the deaf-mute sign language recognition system, the states of the far interphalangeal joints of the little finger, ring finger, middle finger, and index finger of the hand are basically the same as the proximal interphalangeal joints, so the above four joints are no longer set. The sensing area of the far interphalangeal joint of only one finger, and the remaining sensing areas are configured as follows Figure 14 shown. The glove base 2 has openings at the fingertips of the little finger, ring finger, middle finger and index finger (that is, the part other than the far interphalangeal joint) to expose the fingertips. This reduces inhibition of flexion or extension during flexion or extension of the fingers, and reduces discomfort to the wearer due to tension in the dorsal side of the hand. And the exposure of the fingertips is helpful to the use of the touch screen electronic equipment. In this example, ...

Embodiment 3

[0058] The present invention also provides an embodiment, the configuration of the self-powered strain sensing yarn 7 and the glove base 2 is not limited to the plating process, and can also be used such as Figure 16 The jacquard process shown, the resulting data gloves are lighter, thinner and more breathable. Optional configuration methods include warp interlining, weft interlining and other processes. Similarly, for the data glove with rib, double rib or other fabric structure as the glove base, when integrating the sensing yarn, select an appropriate method for structural integration according to needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com