Pickling compound corrosion inhibitor for thermal equipment and preparation method thereof

A technology of thermal equipment and corrosion inhibitor, which is applied in the field of electric power equipment and chemistry, can solve the problems of strong corrosion, corrosion inhibition performance and corrosion inhibition efficiency that cannot reach the corrosion inhibitor used for pickling, so as to reduce the content and improve corrosion inhibition. Performance and efficiency, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Extraction of Effective Corrosion Inhibition Components of Tea Seed Shell (Extract)

[0038] After natural air-drying of fresh tea seed husks, the temperature is controlled in an oven at 60°C, dried to constant weight, ground into powder with a laboratory pulverizer, and 10.0 g of the powder is accurately weighed and loaded into a Soxhlet extractor. The extractant adopts 75% ethanol whose dosage is 15 times of the weight of the tea seed shell powder, the extraction temperature is 85° C., and the extraction time is 1 hour. The obtained natural corrosion inhibitor extract powder is degreased and decolorized with an appropriate amount of petroleum ether, and then spin-dried in a rotary evaporator, and then dried in a blast drying oven at 60±1°C for 5 hours to obtain tea seed hull corrosion inhibitor powder , and the yield was 15.65%.

Embodiment 2

[0039] Embodiment 2 tea seed husk provides corrosion inhibition performance evaluation method

[0040] Weightlessness

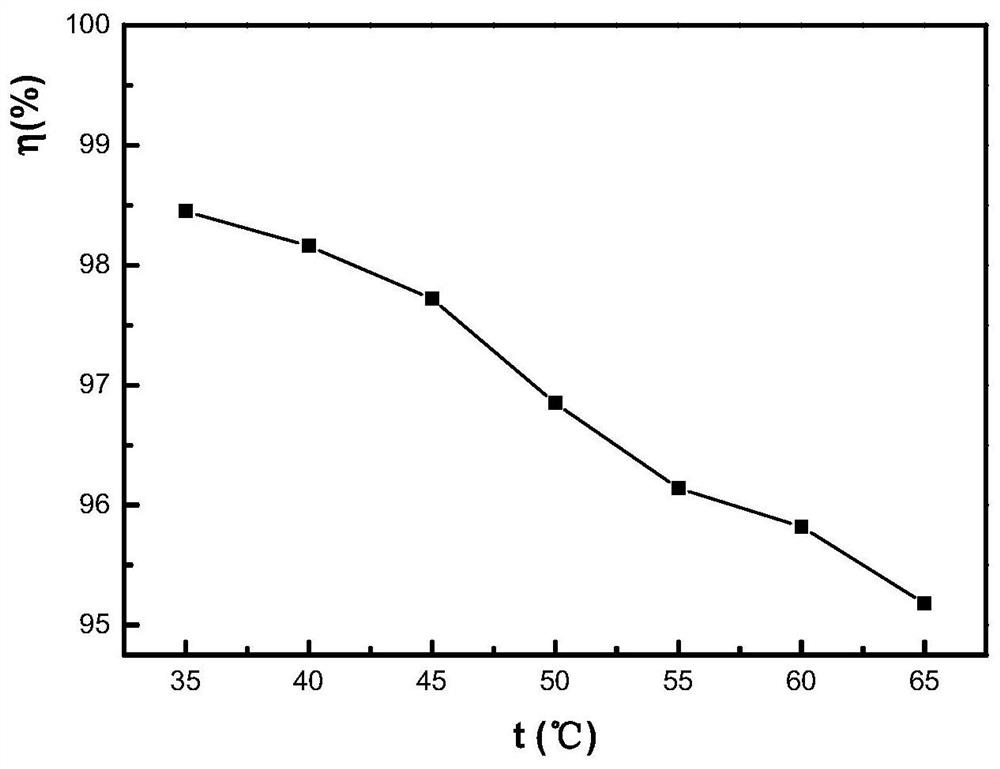

[0041] Referring to the electric power industry standard, the static hanging method is adopted. Before the experiment, the corrosion test piece is polished to the mirror surface with metallographic sandpaper 1#, 2#, 3#, 4#, 5#, 6#, 6#, 7#, and the surface is rough Ra0.4μm, then degreasing with acetone, washing with absolute ethanol, drying with cold air, and finally placing in a desiccator for later use. During the experiment, a number of 250ml beakers were used to configure 200ml of 5% (weight percentage, the same below) hydrochloric acid pickling solution widely used in pickling of thermal equipment. The temperature was controlled at 55±2°C, and a certain amount of tea was added to the above pickling medium Seed husk extract or a compound of a certain amount of tea seed husk extract and other medicines, and no corrosion inhibitor is added to a beaker, as a...

Embodiment 3

[0051] Example 3 tea seed shell extract compound corrosion inhibitor

[0052] Tea seed shell extract compound corrosion inhibitor formula:

[0053] Tea seed husk extract 20-40%, bisimidazoline quaternary ammonium salt 7.0-13.0%, dimethyl ketoxime 1.0-3.0%, sodium alkylbenzene sulfonate 0.75-1.25%, EDTA disodium salt 2.0-4.0% , and the balance is high-purity water.

[0054] Optimum formula of pickling compound corrosion inhibitor for thermal equipment, including 30.0% by weight tea seed hull extract, 10.0% bis-imidazoline quaternary ammonium salt, 2.0% dimethyl ketoxime, 1.0% sodium alkylbenzene sulfonate, EDTA disodium salt 3.0%, and the balance is high-purity water.

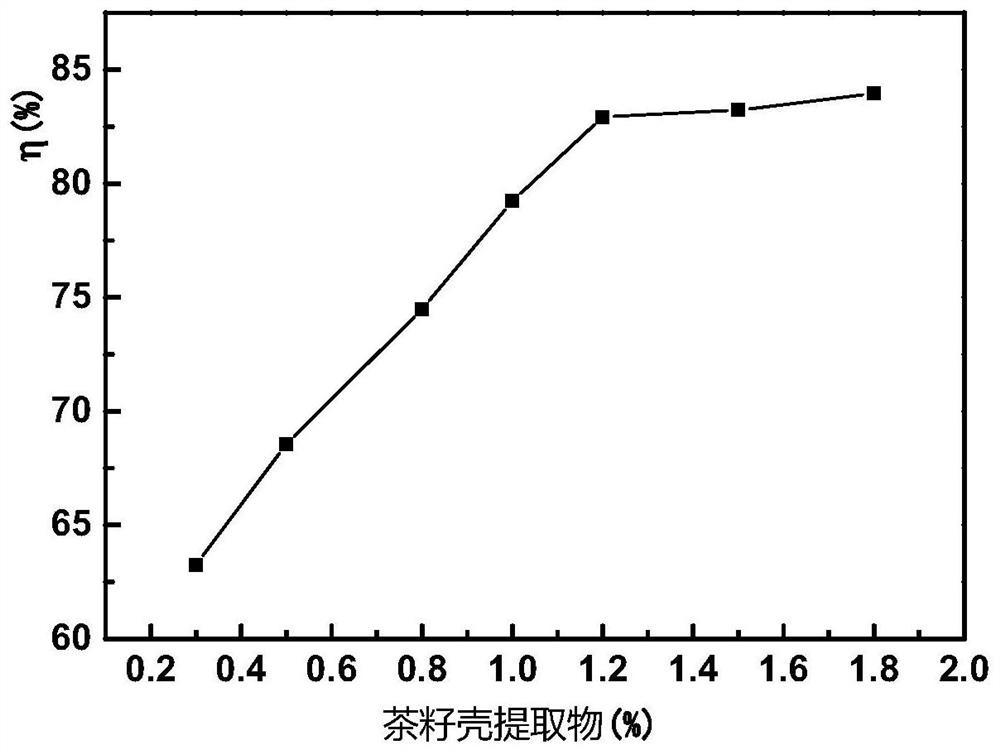

[0055] Based on the optimal formula of the compound corrosion inhibitor, the lotion is formulated at a weight ratio of 1:99 between the compound corrosion inhibitor and 5% hydrochloric acid solution (also known as pickling solution), while keeping the tea seeds in the pickling solution The concentration of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com