Cleaning agent for removing rust scale in plate heat exchanger and preparation method of cleaning agent

A technology of plate heat exchanger and cleaning agent, applied in the field of cleaning agent, to avoid damage, reduce maintenance cost and risk, prolong service life and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

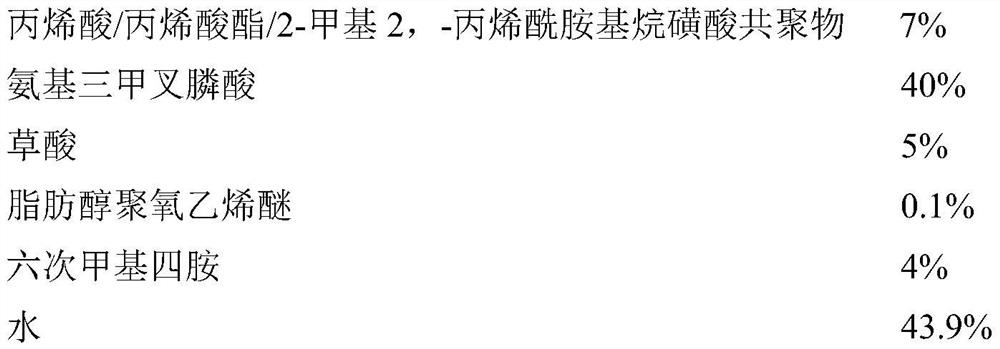

[0023] The present invention is a kind of cleaning agent that is used for removing rust in the plate heat exchanger, and formula is as follows:

[0024]

[0025] The preparation method of the above-mentioned cleaning agent: according to the above ratio, add 219.5 kg of water in the stirred reactor, start stirring, and add 35 kg of acrylic acid / acrylic acid ester / 2-methyl 2'-acrylamido alkane sulfonic acid copolymer successively, 200 kg of aminotrimethylene phosphonic acid, 25 kg of oxalic acid, 0.5 kg of fatty alcohol polyoxyethylene ether, and 20 kg of hexamethylenetetramine, mixed and stirred for 1 hour, until all the agents are completely dissolved and stirred evenly. The temperature is controlled below 50°C during the whole preparation process.

[0026] Dilute 2 tons of the prepared cleaning agent with water 15 times and add it to the plate heat exchanger cleaning cycle system of the central heating system, start the circulation pump to realize cycle cleaning, cycle cle...

Embodiment 2

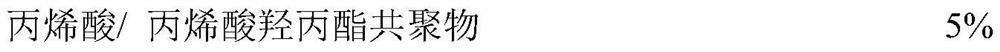

[0030] A kind of cleaning agent that is used for removing rust in the plate heat exchanger of the present invention, formula is as follows:

[0031]

[0032]

[0033] The preparation method of the above-mentioned cleaning agent: according to the above ratio, add 289.75 kg of water in the stirred reactor, start stirring, add 25 kg of acrylic acid / hydroxypropyl acrylate copolymer, 150 kg of diethylenetriaminepentamethylenephosphonic acid, 25 kg of citric acid, 0.25 kg of alkylphenol polyoxyethylene ether, 10 kg of modified imidazoline quaternary ammonium salt, mixed and stirred for 1 hour, until all the medicaments are completely dissolved and stirred evenly. The temperature is controlled below 50°C during the whole preparation process.

[0034] Dilute 2 tons of the prepared cleaning agent with water 10 times and add it to the plate heat exchanger cleaning cycle system of the central heating system, start the circulation pump to realize cycle cleaning, cycle cleaning for 0...

Embodiment 3

[0038] A kind of cleaning agent that is used for removing rust in the plate heat exchanger of the present invention, formula is as follows:

[0039]

[0040] The preparation method of the above-mentioned cleaning agent: according to the above ratio, add 252 kg of water in the stirred reactor, start stirring, and add 40 kg of acrylic acid / allylsulfonic acid copolymer, 175 kg of hydroxyethylidene diphosphonic acid, 25 kg of Tartaric acid, 0.5 kg of fatty alcohol polyoxyethylene ether, 7.5 kg of 2-methylimidazoline, mixed and stirred for 1 hour, until all the agents are completely dissolved and stirred evenly. The temperature is controlled below 50°C during the whole preparation process.

[0041] Dilute 2 tons of the prepared cleaning agent with water 10 times and add it to the plate heat exchanger cleaning cycle system of the central heating system, start the circulation pump to realize cycle cleaning, cycle cleaning for 0.5 hours, soak for 1 hour, recirculate cleaning for 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com