A kind of surface treatment method of 5g with polymer

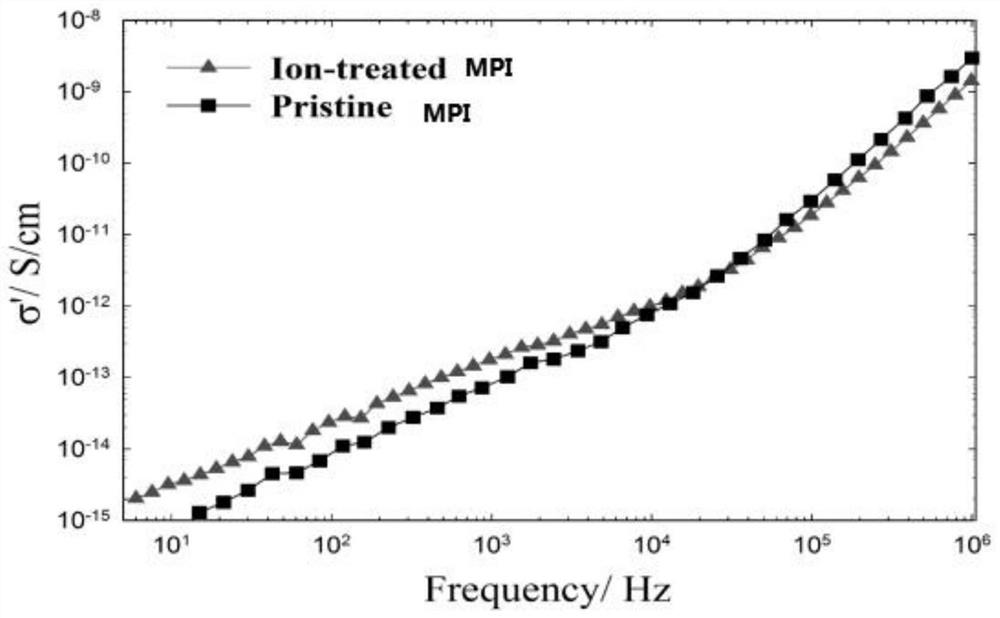

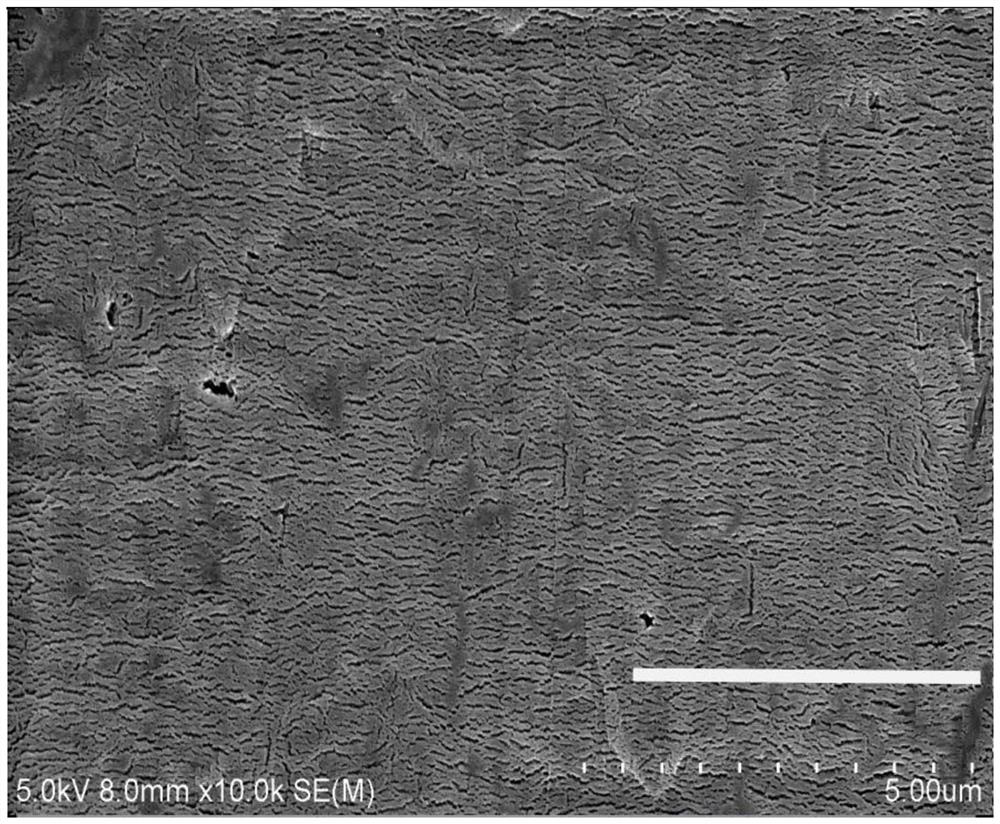

A technology of surface treatment and polymer, applied in the field of surface treatment of polymers for 5G, can solve the problems of inability to improve the bonding strength between polymers and metals or non-metals, processing cost, efficiency and limited effect, insufficient to improve surface energy. , to achieve the effect of low cost, enhanced peel strength and increased roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

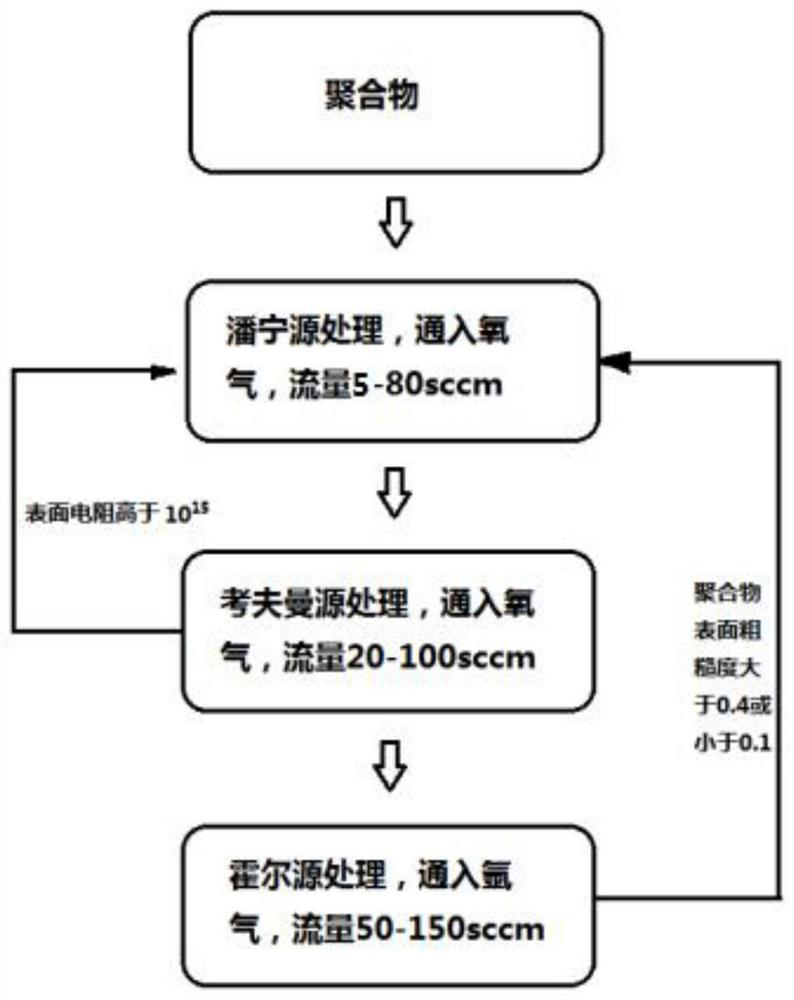

[0047] (1) Using a Penning gas ion source to perform oxygen insertion on the surface of the MPI substrate, the voltage is 30KV, the oxygen flow rate is 60sccm, and the beam intensity is 25mA, so that the roughness of the substrate surface changes ≤ 0.1 μm, and the first polymer is obtained;

[0048] (2) Utilize the Kaufman gas ion source to carry out oxygen addition to the surface of the first polymer, the voltage is 15KV, the gas flow rate is 50sccm, and the beam intensity is 150mA, so that the roughness of the polymer surface changes ≤ 0.1 μm, and the second polymer surface is obtained. polymer; the surface resistance of the second polymer is 2×10 15 Ω, return to step (1), and perform oxygen insertion and oxygen addition in sequence, until the surface resistance of the second polymer is less than 10 15 Ω;

[0049] (3) Utilize the Hall source gas ion source to carry out hydrogen extraction on the surface of the second polymer, voltage 800V, gas flow 100sccm, beam intensity 8...

Embodiment 2

[0051] (1) Oxygen intercalation is performed on the surface of the MPI substrate using a Penning gas ion source, with a voltage of 20KV, an oxygen flow rate of 60sccm, and a beam intensity of 25mA; so that the roughness of the substrate surface changes ≤ 0.1 μm, and the first polymer is obtained;

[0052] (2) Using a Kaufmann gas ion source to add oxygen to the surface of the first polymer, the voltage is 10KV, the gas flow rate is 50sccm, and the beam intensity is 100mA, so that the roughness of the substrate surface changes ≤ 0.1 μm, and the second polymer is obtained; The surface resistance of the second polymer is 2 x 10 15 Ω, return to step (1), and perform oxygen insertion and oxygen addition in sequence, until the surface resistance of the second polymer is less than 10 15 Ω;,

[0053] (3) Utilize Hall source gas ion source to carry out hydrogen extraction on the surface of the second polymer, voltage 500V, gas flow rate 110sccm, beam intensity 800mA, obtain the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com