A kind of uv photolysis air purification equipment with dust removal function

An air purification equipment and photolysis technology, applied in mechanical equipment, gasification materials, lighting and heating equipment, etc., can solve the problem of reducing the reliability of UV photolysis air purification equipment, affecting the waste gas treatment work of UV lamps, and affecting the effect of waste gas treatment. and other problems, to achieve the effect of improving the anti-clogging effect, reducing the dust content and reducing the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

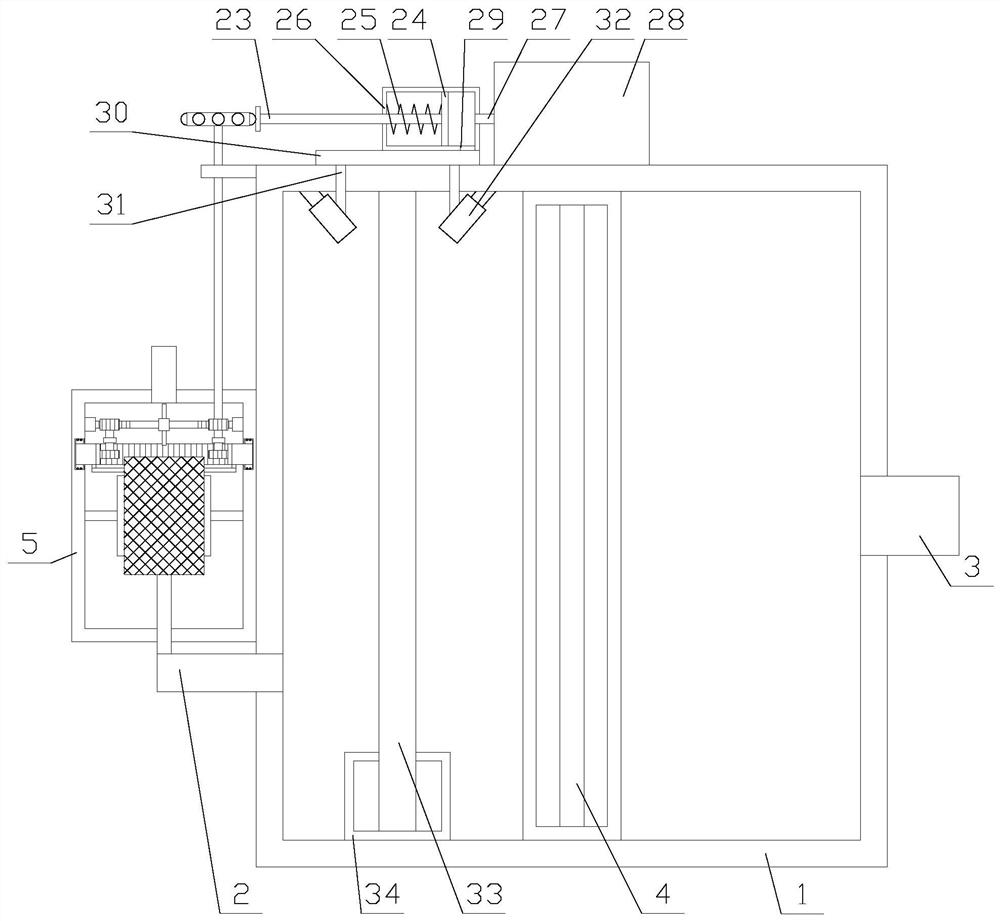

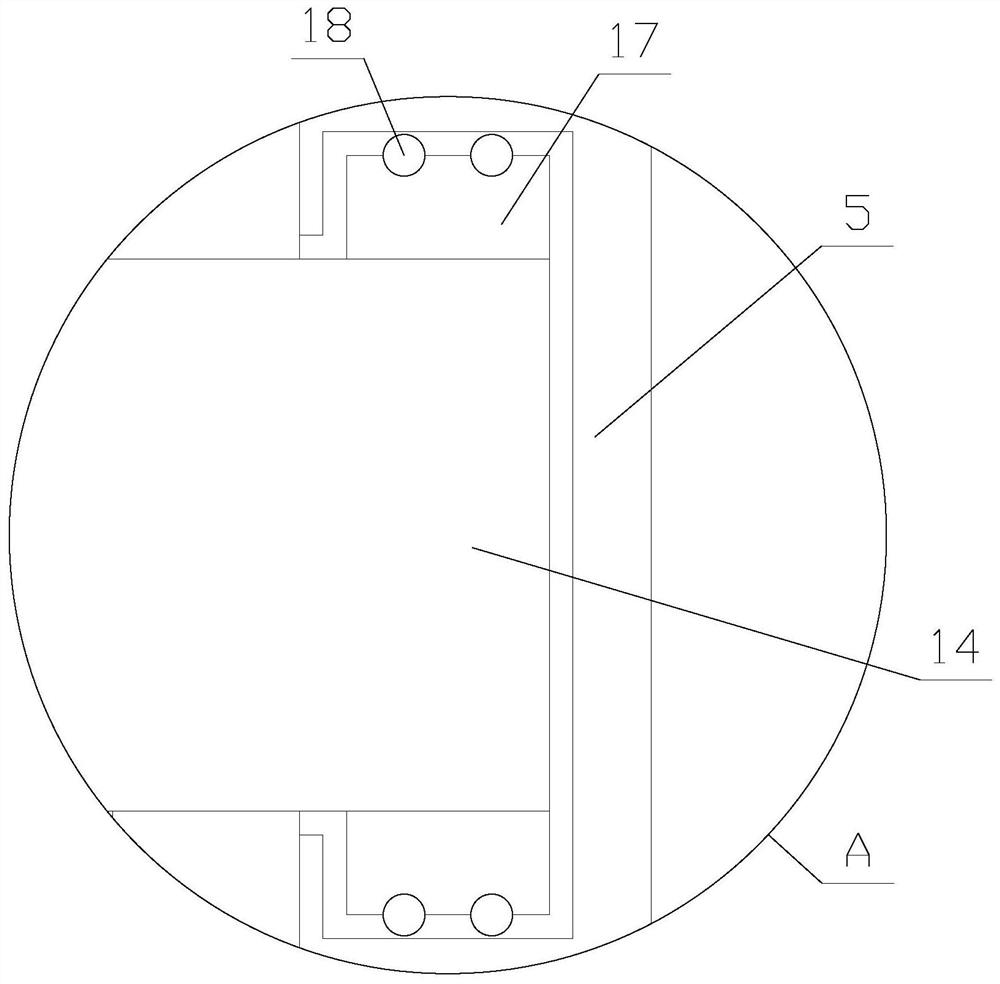

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] like figure 1 Shown, a kind of UV photolysis air purification equipment with dedusting function comprises main body 1, air inlet pipe 2, air outlet pipe 3 and UV lamp 4, and described UV lamp 4 is fixed on the inside of main body 1, and described air inlet pipe 2 and The air outlet pipes 3 are respectively arranged on both sides of the main body 1, and the air inlet pipe 2 and the air outlet pipe 3 are all communicated with the main body 1, and also include a dust removal mechanism and a heat dissipation mechanism. On the side, the dust removal mechanism is connected to the end of the intake pipe 2 away from the main body 1, the heat dissipation mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com