Sizing process of synthetic fiber filament in short fiber sizing machine

A technology of synthetic fiber filament and short fiber pulp, which is applied in fiber type, fiber treatment, liquid/gas/steam yarn/filament treatment, etc., and can solve problems such as many warp beam breaks, yarn divergence, and few colors , to achieve the effects of strong production adaptability, improved weaving efficiency, and low PVA content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] NYLON70D filament fiber variety CK10101-1800194-1, gray fabric size 130*100*65.5, warp beam 13, white 626*7, blue 689*6 white and blue are evenly layered and go in two size tanks.

[0026] 1. Sizing equipment: Japanese Tsudakoma type single-dip double-press staple fiber sizing machine.

[0027] 2. Slurry formula:

[0028] name Special size for filament PVA antistatic agent Dosage(kg) 250 20 5

[0029] 3. Sizing process

[0030] 1) Normal temperature sizing: normal pressure pulping, add 300L demineralized water to the pulping tank, open the agitator and slowly put in 20kg PVA polyvinyl alcohol to raise the temperature to 100°C, after the slurry is completely gelatinized, open the pulping tank cover and naturally cool down to room temperature 35 ℃, put in 250kg of special slurry for filaments and 5kg of antistatic agent, and mix and stir;

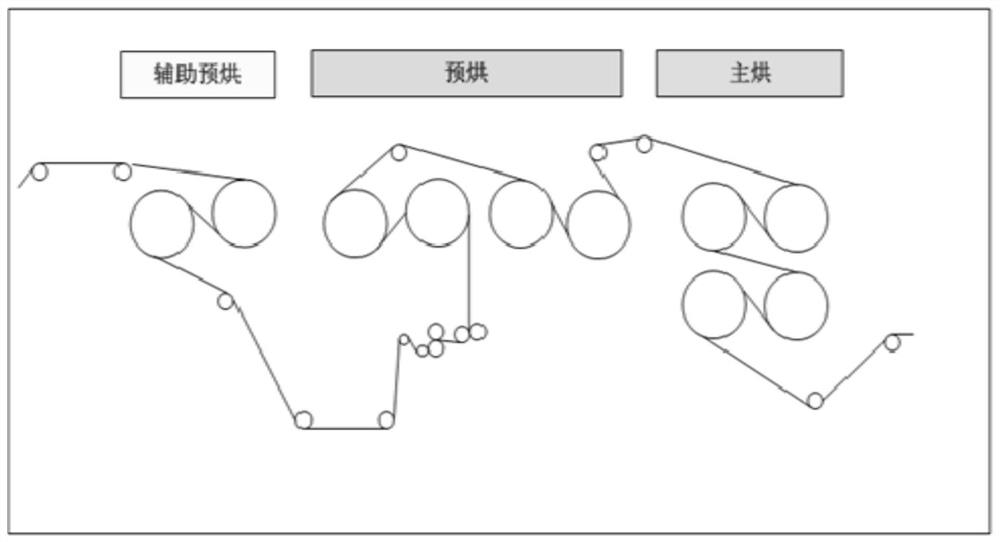

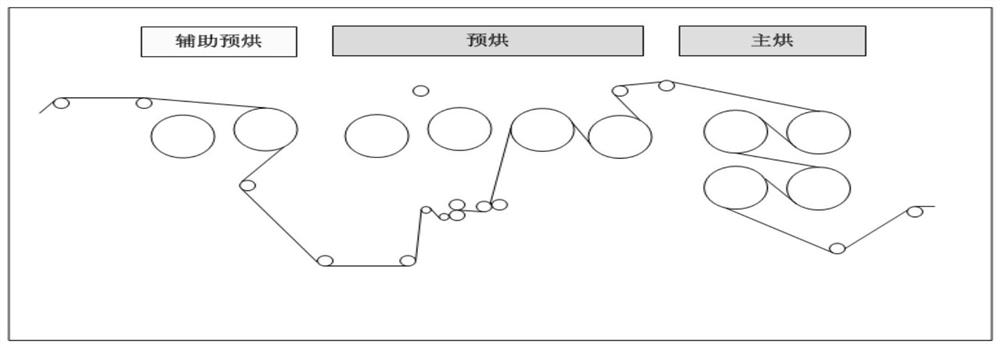

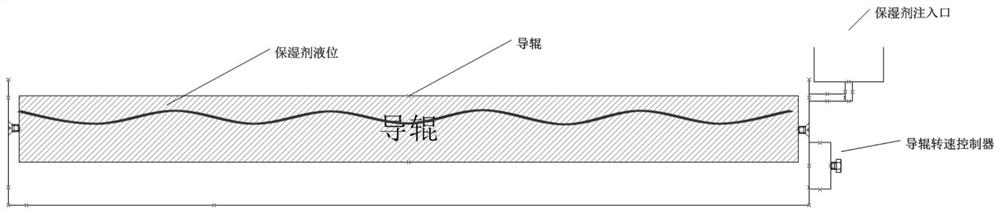

[0031] 2) Drying route: Auxiliary pre-drying and pre-drying each reduce a group of drying cylinders. W...

Embodiment 2

[0041] NYLON70D filament fiber variety CK10101-1800186-1, gray fabric size 130*100*65.5, warp beam 13, white 678*8, blue 620*5 white and blue are evenly layered and go through two size tanks.

[0042] 1. Sizing equipment: Japanese Tsudakoma type single-dip double-press staple fiber sizing machine.

[0043] 2. Slurry formula:

[0044] name Special size for filament PVA antistatic agent Dosage(kg) 250 15 5

[0045] 3. Sizing process

[0046] 1) Sizing at room temperature: Sizing at normal pressure, adding 300L of demineralized water to the mixing tank, slowly putting in 15kg of PVA polyvinyl alcohol in the mixer and raising the temperature to 100°C. ℃, put into 250kg of special slurry for main slurry filament and 5kg of antistatic agent, mix and stir;

[0047]2) Drying route: Auxiliary pre-drying and pre-drying each reduce a group of drying cylinders. Walking route: auxiliary pre-drying (1 drying cylinder) → pre-drying (2 drying cylinders) → main d...

Embodiment 3

[0056] NYLON70D filament fiber variety CK10101-1800199-1, gray fabric specification 130*100*65.5, warp beam 12, white 695*6, dark blue 755*5, blue 582*1 and white one size slot, Dark blue and blue go together for a pulp trough.

[0057] 1. Sizing equipment: Japanese Tsudakoma type single-dip double-press staple fiber sizing machine.

[0058] 2. Slurry formula:

[0059] name Special size for filament PVA antistatic agent Dosage(kg) 250 25 5

[0060] 3. Sizing process

[0061] 1) Normal temperature sizing: normal pressure pulping, add 300L demineralized water to the pulping tank, turn on the agitator and slowly add 25kg of PVA polyvinyl alcohol to raise the temperature to 100°C. , put in 250kg of special slurry for main slurry filament and 5kg of antistatic agent, mix and stir;

[0062] 2) Drying route: Auxiliary pre-drying and pre-drying each reduce a group of drying cylinders. Walking route: auxiliary pre-drying (1 drying cylinder) → pre-drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com