Preparation method of a thermally conductive elastic shape-setting phase change energy storage material

A technology of shape-setting phase change and energy storage materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., to achieve good environmental friendliness, high enthalpy change value, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

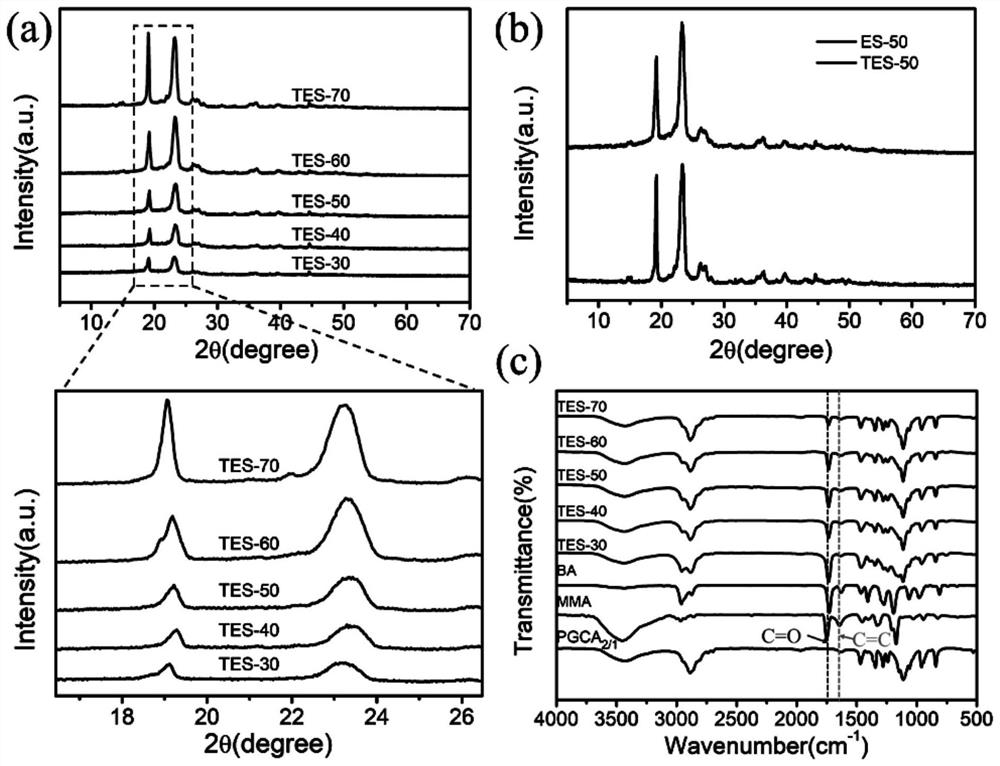

Image

Examples

Embodiment 1

[0046] A method for preparing a thermally conductive elastic shape-setting phase-change energy storage material, comprising the following steps:

[0047] Step 1. Prepare graphene oxide (GO) by the improved Hummers method, prepare 1.75 mg / mL graphene oxide solution, add 21.875 mg carbon nanotubes (CNTs) to 25 mL graphene oxide solution, stir magnetically for 30 min, and ultrasonically 60min to obtain a homogeneous mixed solution, add 0.052g reducing agent sodium bisulfite to the homogeneous mixed solution, stir for 5min, and then place it in a 95°C oven for self-assembly reaction for 5h, that is, self-assembled graphene oxide / carbon nanotubes Hybrid hydrogel; place the obtained graphene oxide / carbon nanotube hybrid hydrogel in 10% ethanol aqueous solution for dialysis for 48 hours, pre-freeze the dialyzed hydrogel in the refrigerator for 24 hours, and place in- Freeze-dry at 50°C for more than 48 hours to obtain graphene oxide / carbon nanotube hybrid airgel (GCA);

[0048] Step...

Embodiment 2

[0051] A method for preparing a thermally conductive elastic shape-setting phase-change energy storage material, comprising the following steps:

[0052] Step 1. Prepare graphene oxide (GO) by the improved Hummers method, prepare 1.75 mg / mL graphene oxide solution, add 21.875 mg carbon nanotubes (CNTs) to 25 mL graphene oxide solution, stir magnetically for 30 min, and ultrasonically 60min to obtain a homogeneous mixed solution, add 0.052g reducing agent sodium bisulfite to the homogeneous mixed solution, stir for 5min, and then place it in a 95°C oven for self-assembly reaction for 5h, that is, self-assembled graphene oxide / carbon nanotubes Hybrid hydrogel; place the obtained graphene oxide / carbon nanotube hybrid hydrogel in 10% ethanol aqueous solution for dialysis for 48 hours, pre-freeze the dialyzed hydrogel in the refrigerator for 24 hours, and place in- Freeze drying at 50°C for more than 48 hours to obtain graphene oxide / carbon nanotube hybrid airgel;

[0053] Step 2:...

Embodiment 3

[0056] A method for preparing a thermally conductive elastic shape-setting phase-change energy storage material, comprising the following steps:

[0057] Step 1. Prepare graphene oxide (GO) by the improved Hummers method, prepare 1.75 mg / mL graphene oxide solution, add 21.875 mg carbon nanotubes (CNTs) to 25 mL graphene oxide solution, stir magnetically for 30 min, and ultrasonically 60min to obtain a homogeneous mixed solution, add 0.052g reducing agent sodium bisulfite to the homogeneous mixed solution, stir for 5min, and then place it in a 95°C oven for self-assembly reaction for 5h, that is, self-assembled graphene oxide / carbon nanotubes Hybrid hydrogel; place the obtained graphene oxide / carbon nanotube hybrid hydrogel in 10% ethanol aqueous solution for dialysis for 48 hours, pre-freeze the dialyzed hydrogel in the refrigerator for 24 hours, and place in- Freeze drying at 50°C for more than 48 hours to obtain graphene oxide / carbon nanotube hybrid airgel;

[0058] Step 2:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com