A method and device for treating semi-coke wastewater

A semi-coke wastewater and treatment method technology, applied in water/sewage treatment, water/sewage multi-stage treatment, degassed water/sewage treatment, etc., can solve low removal efficiency, microbial toxicity in biochemical section, and difficult biochemical degradation To achieve the effect of improving the efficiency of extraction and dephenolization, enhancing the anti-fouling performance and improving the operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

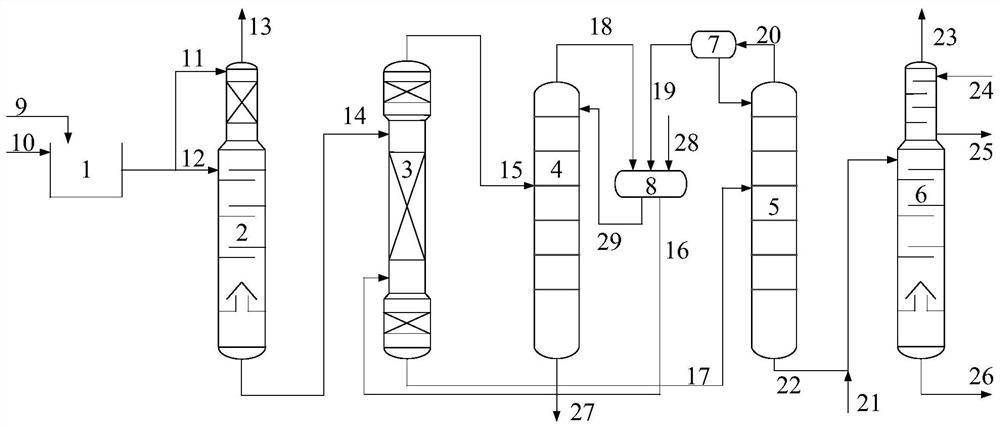

[0060] The flow rate is 100t / h, the total phenol content is about 12000mg / L, the total ammonia content is about 2500mg / L, the CO 2 Content about 3400mg / L, H 2 S content is about 80mg / L, oil content is about 1200mg / L, COD Cr The value is about 35000mg / L, the pH value is 7.8, the chromaticity is 22000 times, and the water temperature is 37℃. figure 1 process as shown. The extractant uses MIBK, the mol ratio of NaOH in the 20wt% NaOH solution and the fixed ammonium in the still liquid of the solvent stripping tower is 1:0.98, and the parameters such as the number of stages, pressure and temperature of each tower are as follows:

[0061] The acid adding device adjusts the pH value of the semi-coke wastewater to 5.1, and the added acid is concentrated sulfuric acid, which is uniformly mixed and left to stand for 2.5 hours.

[0062] The deacidification tower has 15 theoretical stages, the ratio of cold and hot feeds is 3:17, the temperature at the top of the tower is 38°C, the pr...

Embodiment 2

[0069] The flow rate is 20t / h, the total phenol content is about 14000mg / L, the total ammonia content is about 2300mg / L, the CO 2 Content about 3000mg / L, H 2 S content is about 100mg / L, oil content is about 1500mg / L, COD Cr Value of about 48000mg / L, chromaticity of 25000 times, pH value of 7.5, water temperature of 40 ℃ to be treated blue charcoal wastewater by figure 1 process as shown. The extraction agent uses a mixed extraction agent (the volume ratio of MIBK and n-PTL is 3:2), the molar ratio of NaOH in the 20wt% NaOH solution to the fixed ammonium in the solvent stripping column liquid is 1:0.95, and the stages of each column , pressure, temperature and other parameters are as follows:

[0070] The acid adding device adjusts the pH value of the semi-coke wastewater to 4.8, and the added acid is concentrated sulfuric acid, which is uniformly mixed and left to stand for 5 hours.

[0071] The deacidification tower has 13 theoretical stages, the ratio of cold and hot fee...

Embodiment 3

[0078] The flow rate is 300 tons / hour, the total phenol content is about 8000mg / L, the total ammonia content is about 3300mg / L, CO 2 Content about 4000mg / L, H 2 S content is about 50mg / L, oil content is about 1300mg / L, COD Cr Value is about 30000mg / L, chromaticity is 25000 times, pH value is 8.4, water temperature 35℃ figure 1 process as shown. The extractant uses DIPE, the molar ratio of NaOH in the 20wt% NaOH solution to the fixed ammonium in the still liquid of the solvent stripping tower is 1:0.98, and the parameters such as the number of stages, pressure and temperature of each tower are as follows:

[0079] The acid adding device adjusts the pH value to 5.0, and the added acid is concentrated sulfuric acid, which is uniformly mixed and left to stand for 3.5 hours.

[0080] The deacidification tower has 14 theoretical stages, the ratio of cold and hot feed is 3:16, the temperature at the top of the tower is 36°C, the pressure is 0.1MPa, the temperature at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com