Novel anti-scum slag hopper of large-sized coal-fired power plant slag-tap boiler

A technology for liquid slag removal and coal-fired power plants, which is applied to the safety devices of combustion chambers, combustion chambers, and combustion methods. It can solve problems affecting the safe operation of boilers and clogging of slag hoppers, and prevents smoke from leaking and polluting the production site. , Prevent scum generation, enhance the effect of slag hopper air leakage prevention and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

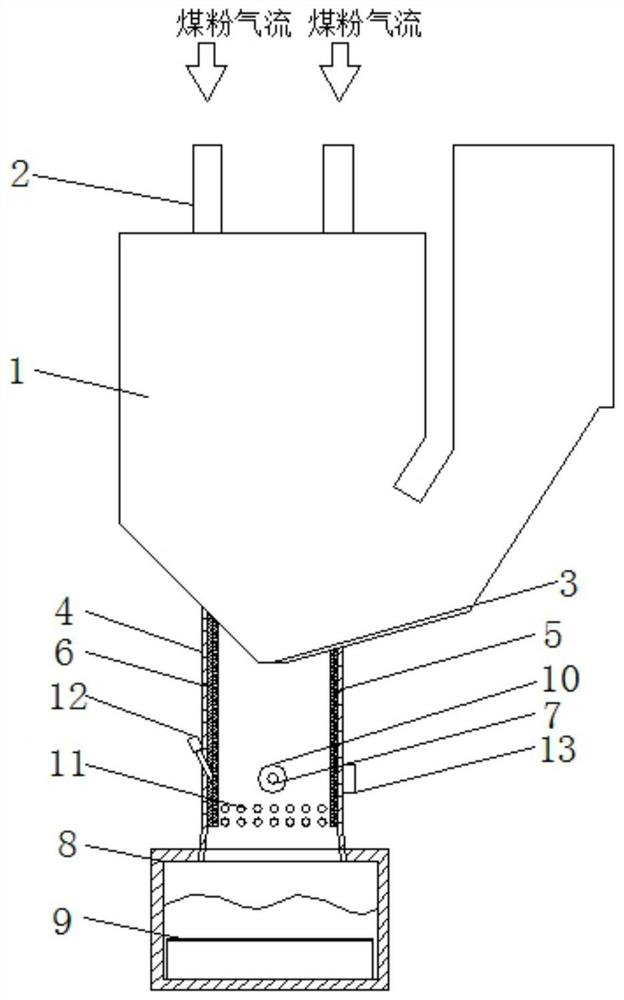

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

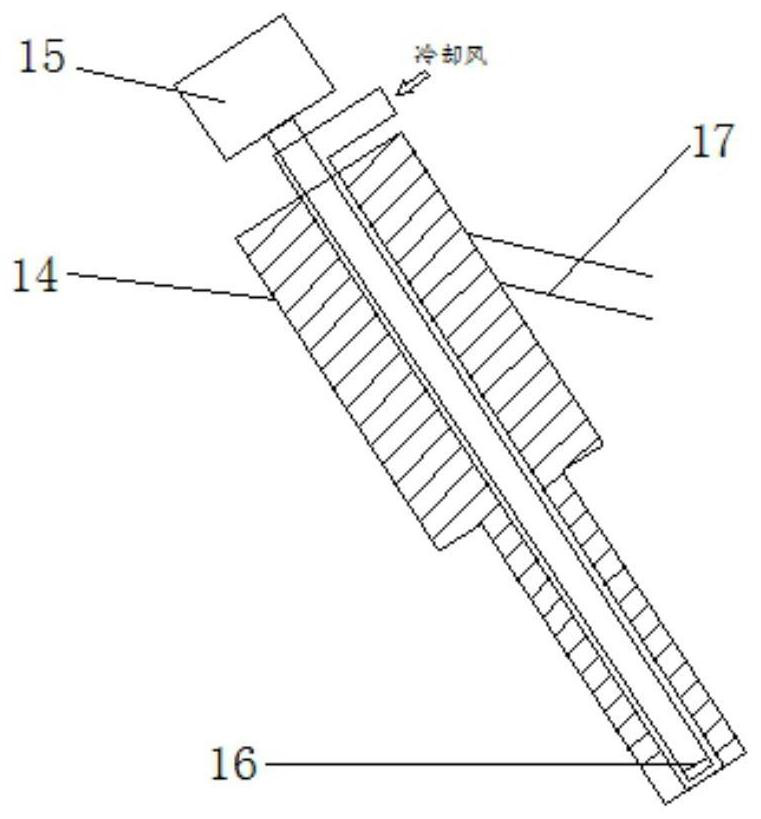

[0023] refer to Figure 1-2 , a new type of anti-scum slag hopper for a large-scale coal-fired power plant liquid slag discharge boiler, including a slag hopper body 4, the inner wall of the slag hopper body 4 is provided with a common castable insulation layer 6, and one side of the normal castable insulation layer 6 There is a corundum insulation layer 5 on the outer wall, a waste gas pipe 7 is arranged on one side of the outer wall of the slag hopper body 4, and an inclined installation opening is opened on one side of the outer wall of the slag hopper body 4, and the inner wall of the installation opening is fixedly connected with a slag pool monitoring system 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com