A slag secondary granulation rotor

A secondary granulation and rotor technology, which is applied in the field of metallurgy and power machinery, can solve the problems of heavy system maintenance workload, inability to recycle slag, and large consumption of new water, and achieve low resource consumption, easy cleaning and maintenance, and heat dissipation. fast exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

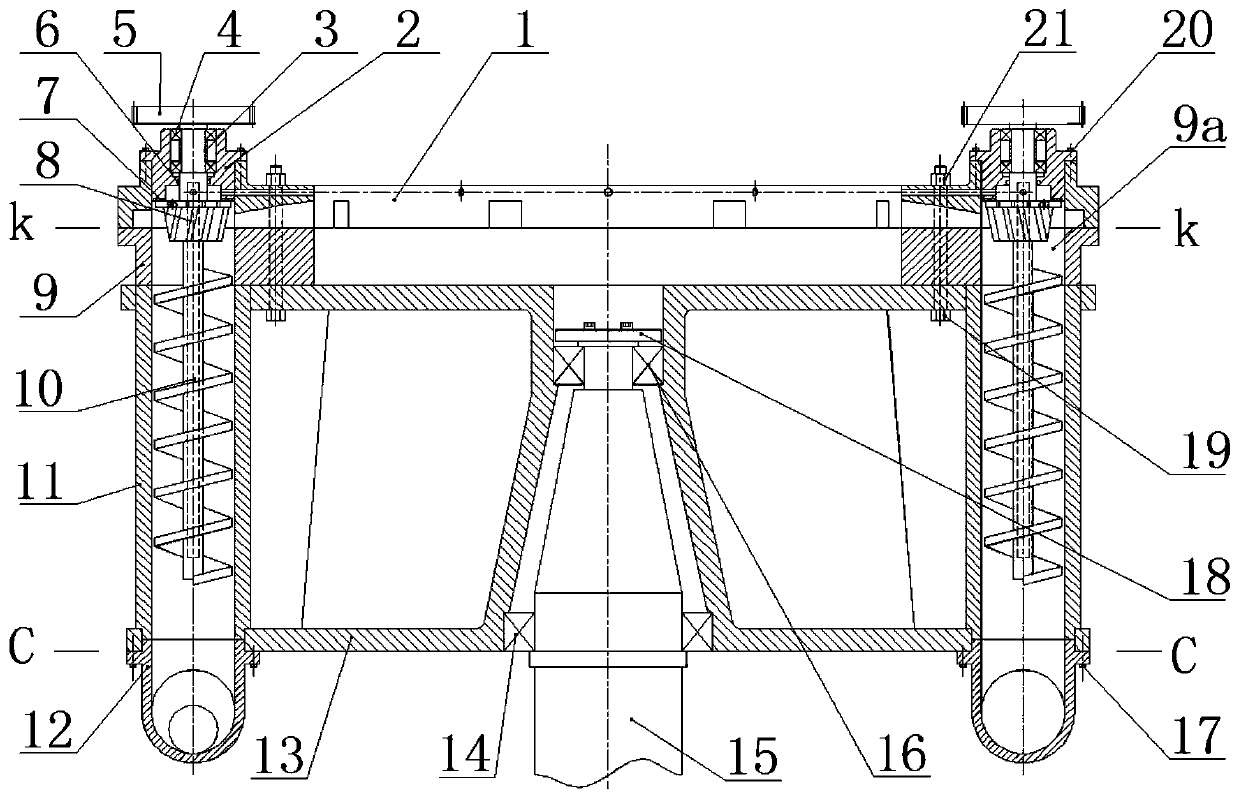

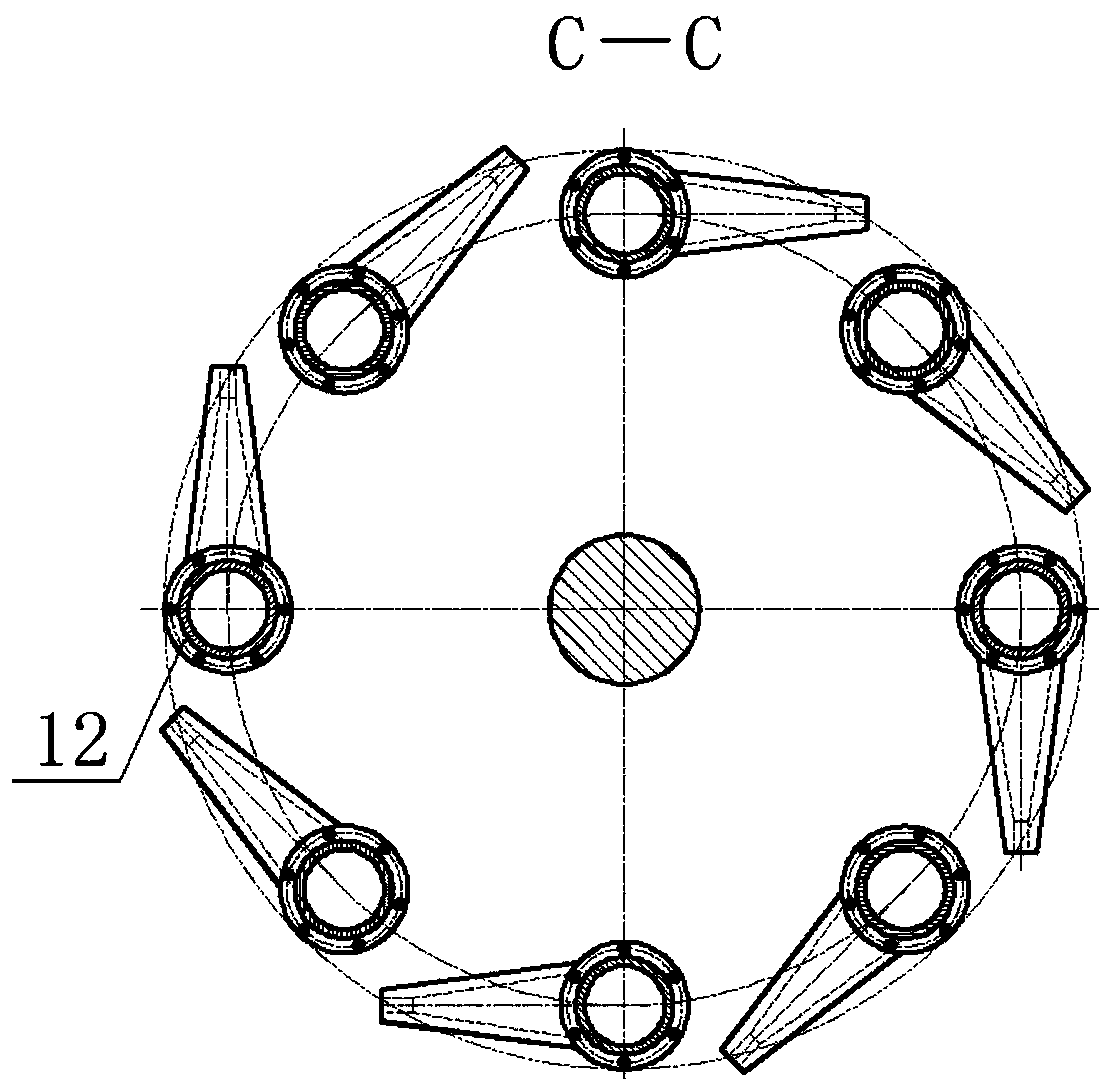

[0020] figure 1 The hollow tube 11 is connected with the upper and lower discs of the bracket 13, the transition disc 9 and the volute disc 1 are sequentially coaxially mounted on the upper disc of the bracket 13, and are fastened and connected by bolts 19 and nuts 21 to form a rigid rotor body; The bracket 13 is supported on the vertical fixed shaft 15 by the upper bearing 16 and the lower bearing 14, the top of the fixed shaft 15 is fixedly connected with the pressure plate 18 to form the axial positioning of the bracket 13; the nozzle 12 is fixedly installed on the lower part of the bracket 13 by the lower bolt 17 .

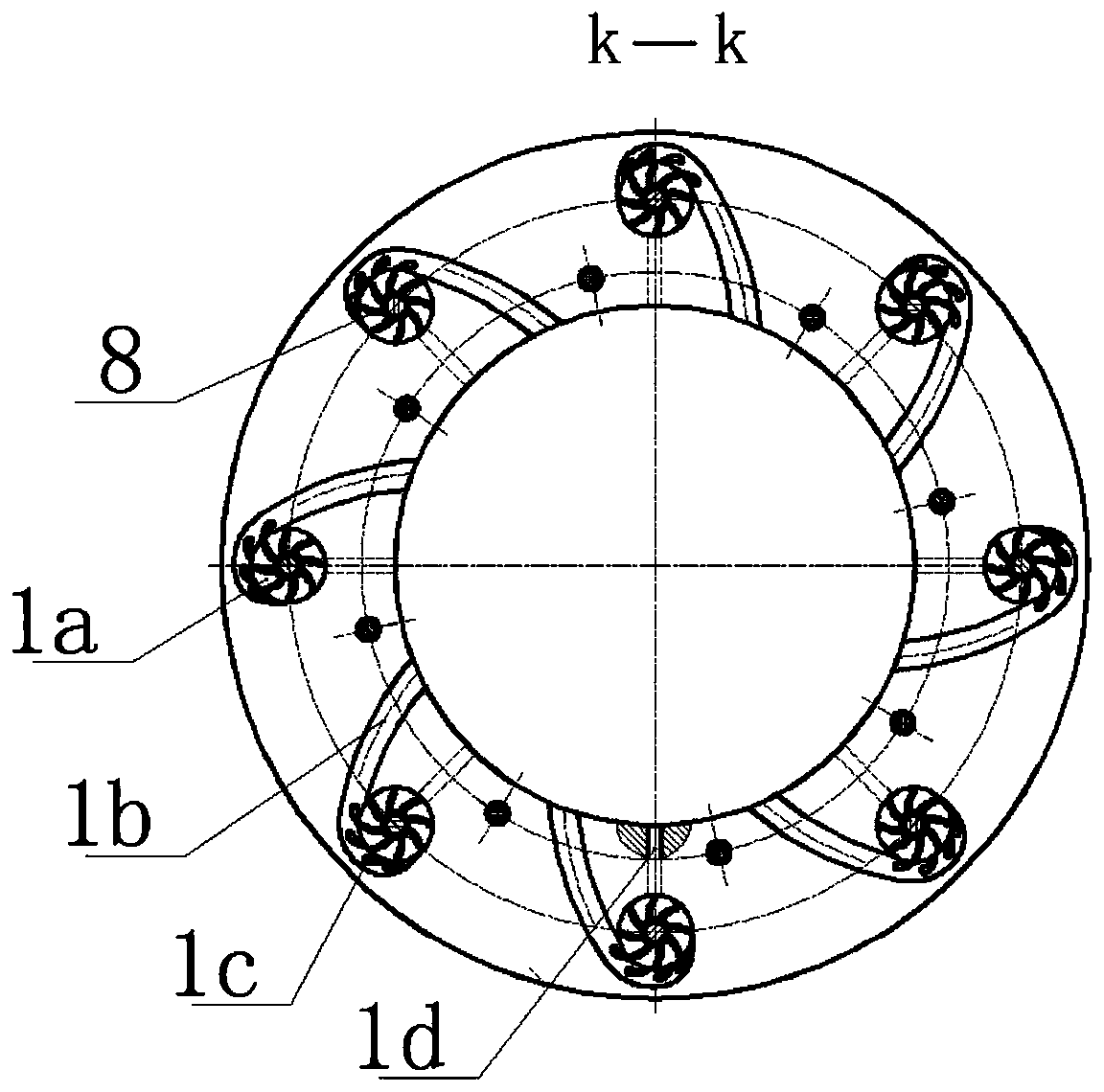

[0021] The sealing ring 6 is installed in the inner hole of the bearing seat 2, the lower end of the bearing seat is fixedly connected with the gasket 7, and the screw rod 9 connected with the turbine 8 in the circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com