Method for local ion nitriding of deep cavity thread of titanium alloy part

A technology of ion nitriding and titanium alloy, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of not meeting the requirements of thread wear resistance, uneven distribution of nitriding layer depth, deep cavity No nitriding and other problems can be achieved to shorten the nitriding time, avoid hydrogen embrittlement and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

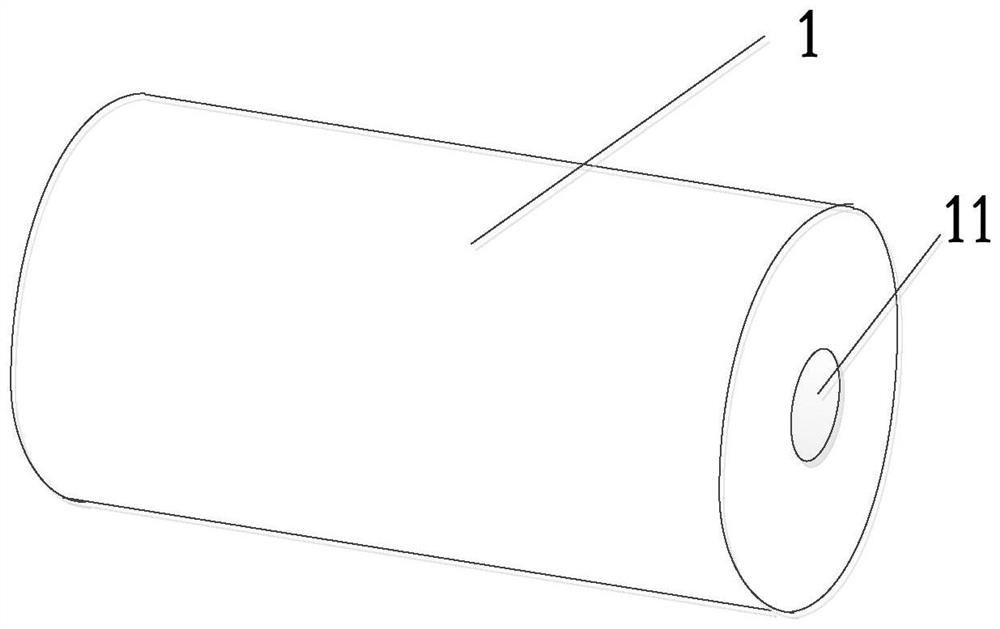

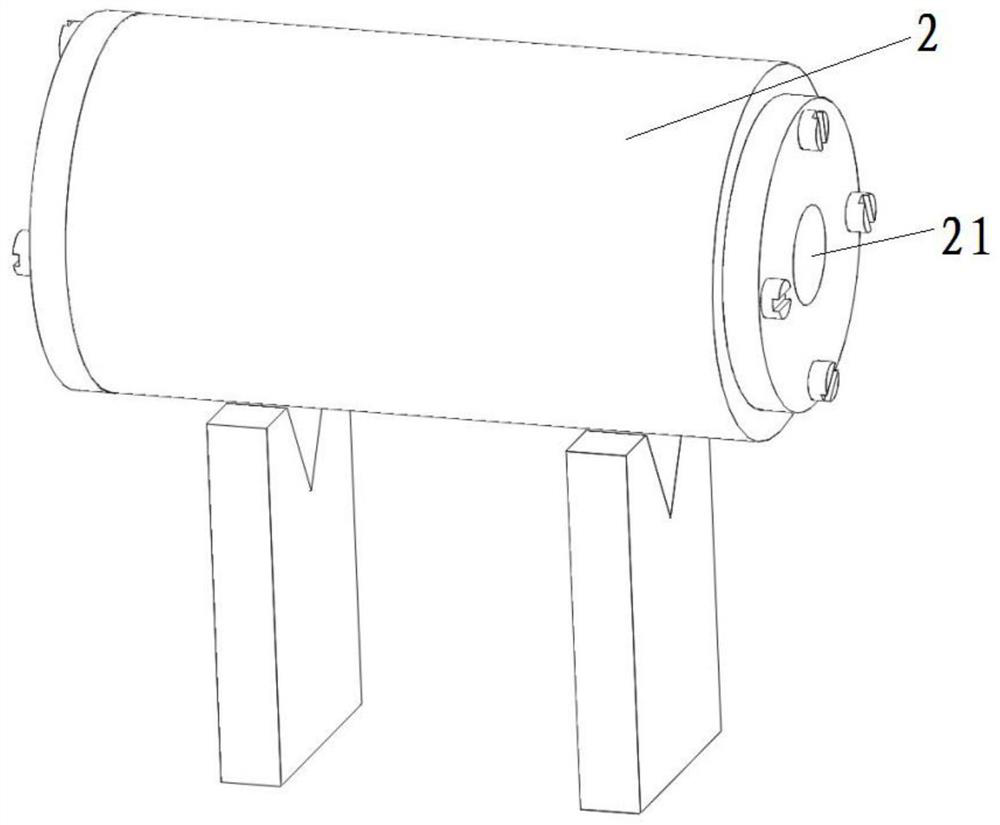

[0064] 1) Nitriding tooling 2 is designed according to the size and shape of the titanium alloy part 1 to protect the outer surface and both ends of the titanium alloy part 1 and expose the inner cavity of the end face.

[0065] 2) Carry out vacuum annealing heat treatment on the nitriding tooling 2, and the heat treatment parameters are as follows:

[0066] Furnace loading method: room temperature furnace;

[0067] Heating rate: 10°C / min;

[0068] Vacuum annealing temperature: 830°C;

[0069] Heat preservation: 2h;

[0070] Cooling: The furnace temperature is below 150°C.

[0071] 3) Use absolute ethanol to wipe the entire outer surface and inner cavity of the nitriding tooling 2 and the titanium alloy part 1 in the step, and blow dry with compressed air;

[0072] 4) Fix the titanium alloy part 1 in the nitriding tooling 2, and adjust the tooling so that both ends of the inner cavity are unobstructed;

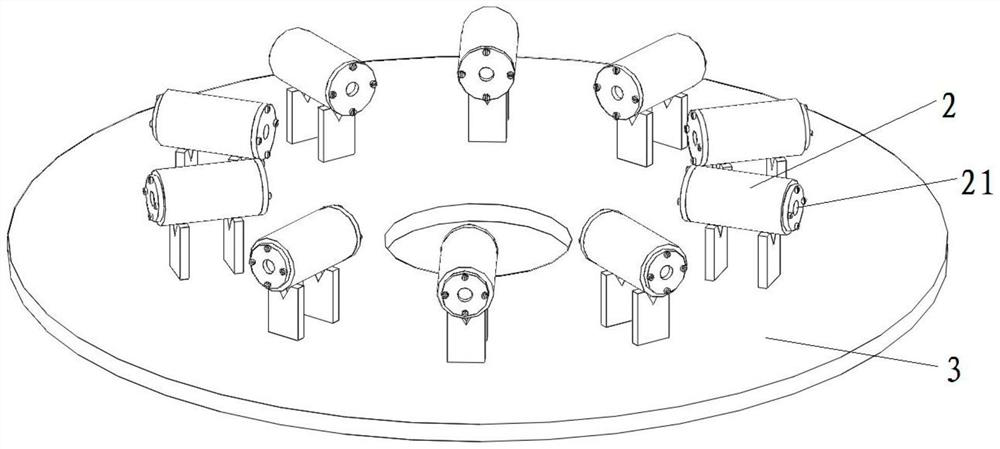

[0073] 5) Evenly distribute the middle nitriding tooling 2 (equipped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com