Environment-friendly hot-melt marking coating and preparation method thereof

A hot-melt marking paint, environmentally friendly technology, applied in the direction of reflection/signal paint, coating, conjugated diene coating, etc., can solve serious, pollution, crack resistance, compressive strength and fluidity performance indicators Substandard and other problems, to achieve the effect of prolonging service life, reducing pollution, acid and alkali resistance and reflective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The environment-friendly type hot-melt marking paint of the present embodiment is made by the raw material of following weight: modified C5 petroleum resin 13kg, chrome yellow 8kg, quartz sand 27kg, heavy calcium carbonate 28kg, castor oil 1kg, polyethylene wax 4kg, Powdered nitrile rubber 1kg and glass microspheres 23kg.

[0080] Wherein, the modified C5 petroleum resin is prepared by the following method:

[0081] Step 1.1: Weigh the following raw materials to make: 100kg of C5 petroleum resin, 12kg of maleic anhydride and 17kg of powdered nitrile rubber;

[0082] Step 1.2: heat up the 60% by weight C5 petroleum resin weighed in step 1 to 150° C., feed in nitrogen, stir and melt to obtain a primary stirring liquid;

[0083] Step 1.3: Add the remaining C5 petroleum resin to the primary stirring liquid obtained in step 2, and slowly add the maleic anhydride weighed in step 1 while stirring at 150°C, and stir for 1h-2h to obtain maleic C5 petroleum resin;

[0084] Step...

Embodiment 2

[0096] The environment-friendly hot-melt marking paint of the present embodiment is made of the following raw materials: modified C5 petroleum resin 14kg, pigment 7kg, quartz sand 28kg, heavy calcium carbonate 27kg, castor oil 2kg, polyethylene wax 3kg, powder Nitrile rubber 2kg and glass beads 22kg.

[0097] Wherein, the modified C5 petroleum resin is prepared by the following method:

[0098] Step 1.1: Weigh the following raw materials to make: 100kg of C5 petroleum resin, 13kg of maleic anhydride and 16kg of powdered nitrile rubber;

[0099] Step 1.2: heat up the 62% by weight C5 petroleum resin weighed in step 1 to 152° C., feed in nitrogen, stir and melt to obtain a primary stirring liquid;

[0100] Step 1.3: Add the remaining C5 petroleum resin to the primary stirring liquid obtained in step 2, and slowly add the maleic anhydride weighed in step 1 while stirring at 152°C, and stir for 1.5 hours to obtain maleic C5 petroleum resin;

[0101] Step 1.4: At 198°C, add the p...

Embodiment 3

[0114] The environment-friendly hot-melt marking paint of the present embodiment is made of the following raw materials: modified C5 petroleum resin 15kg, pigment 6kg, quartz sand 29kg, heavy calcium carbonate 26kg, castor oil 3kg, polyethylene wax 2kg, powder Nitrile rubber 3kg and glass beads 20kg.

[0115] Wherein, the modified C5 petroleum resin is prepared by the following method:

[0116] Step 1.1: Weigh the following raw materials to make: 100kg of C5 petroleum resin, 15kg of maleic anhydride and 15kg of powdered nitrile rubber;

[0117] Step 1.2: heat up the 65% by weight C5 petroleum resin weighed in step 1 to 155° C., feed in nitrogen, stir and melt to obtain a primary stirring liquid;

[0118] Step 1.3: Add the remaining C5 petroleum resin to the primary stirring liquid obtained in step 2, and slowly add the maleic anhydride weighed in step 1 while stirring at 155° C., and stir for 2 hours to obtain maleic C5 petroleum resin;

[0119] Step 1.4: At 200°C, add the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

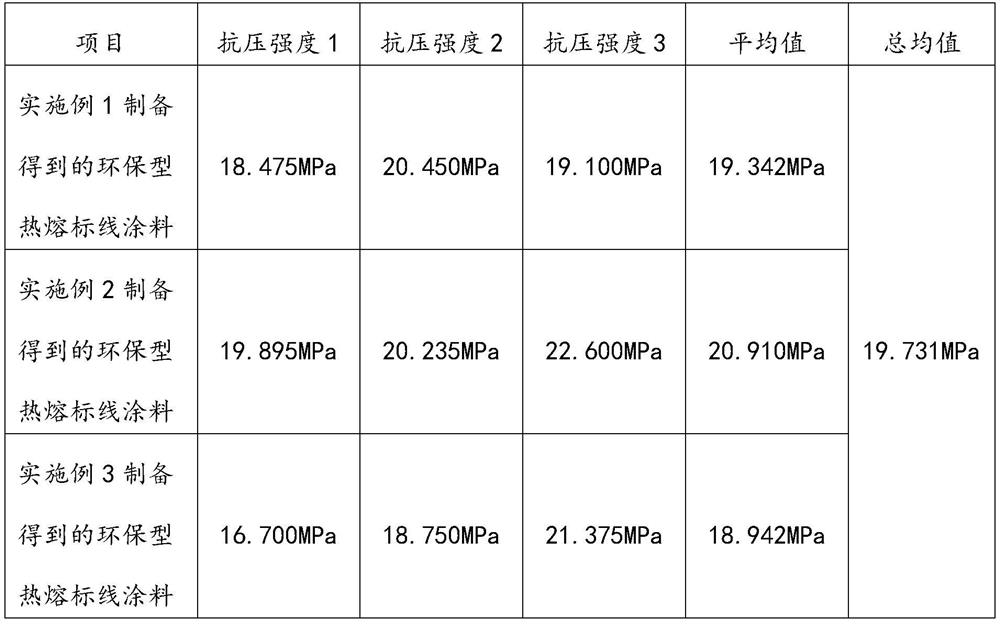

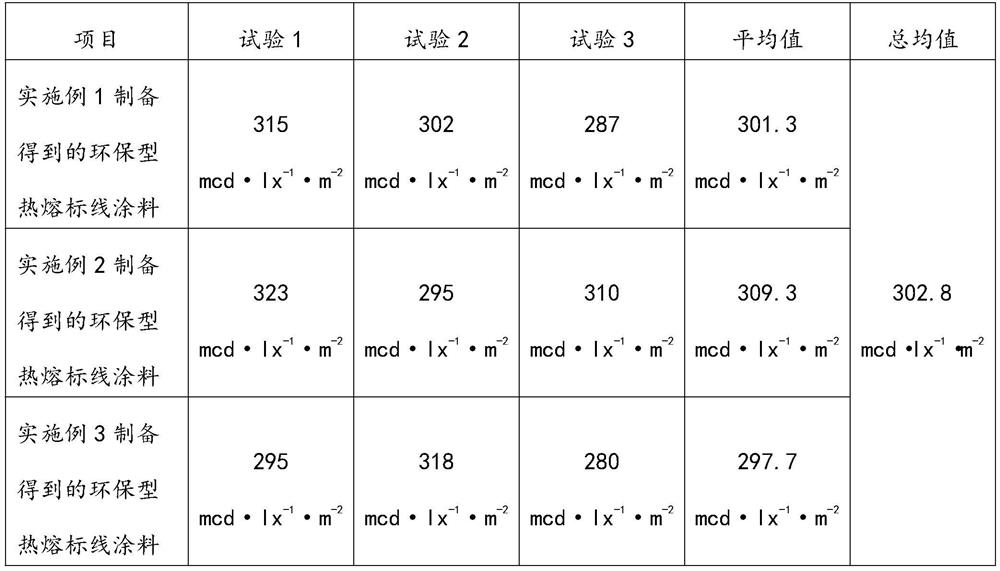

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com