Polypropylene film

A technology of polypropylene film and polypropylene resin, applied in the direction of film/thick film capacitors, ion implantation plating, coating, etc., can solve the problem of increased electrical breakdown rate of materials, shortened life of film capacitors, and poor heat dissipation of film capacitors Uniformity and other problems, to achieve the effect of reduced life and reduced capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

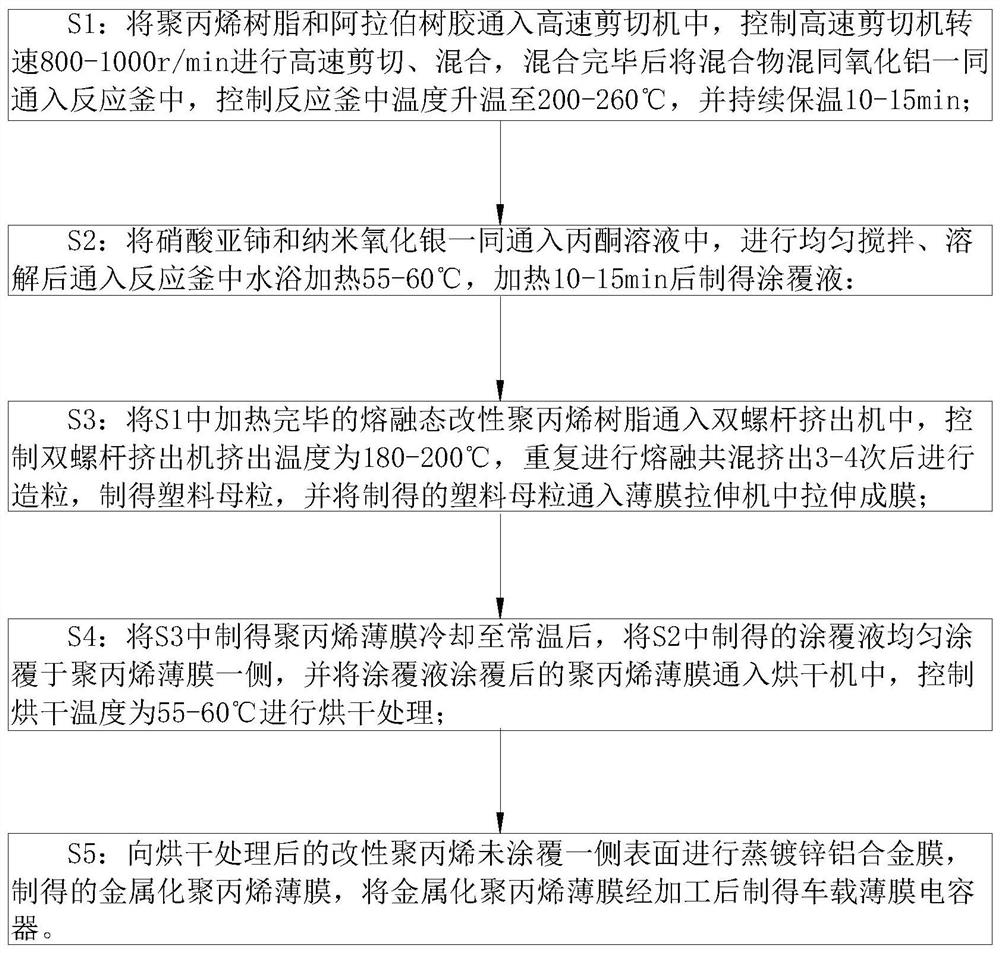

[0032] The preparation method of described polypropylene film comprises the following steps:

[0033] S1: Pass the polypropylene resin and gum arabic into the high-speed shearing machine, control the speed of the high-speed shearing machine to 800-1000r / min for high-speed shearing and mixing, and pass the mixture together with alumina into the reaction kettle after mixing. Control the temperature in the reaction kettle to rise to 200-260°C, and keep it warm for 10-15 minutes; modify the polypropylene resin with gum arabic, and make use of the high-quality viscosity of gum arabic, so that the prepared polypropylene resin film is stretched The intermolecular bonding strength is strong, which effectively prevents tiny voids from being damaged during the stretching process. At the same time, polypropylene resin and gum arabic are mixed at high speed at room temperature to effectively avoid the high viscosity of gum arabic in its molten state. , which is not conducive to the unifor...

Embodiment approach

[0039] As an embodiment of the present invention, wherein the raw material also includes active manganese dioxide powder;

[0040] The selected active manganese dioxide in the raw material can decompose by itself in a high temperature environment, and then release a large amount of oxygen ions by itself, and when there are defects or defects in the metallized film, the current of the metal layer at the defect or defect increases rapidly, and then in the short-term Within a short period of time, the temperature of the metal layer at the defect or defect will increase rapidly to reach the melting point of the metal film. At this time, the heat will be conducted into the polypropylene film and cause the polypropylene film to self-dissolve, and the active manganese dioxide inside will decompose and release oxygen ions. The aluminum vapor at the melting point is in contact with each other to form an aluminum oxide film. The formation of the aluminum oxide film cuts off the electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com