A kind of flexible imitation stone veneer sheet and preparation method thereof

A stone imitation and veneer technology, applied in the field of building materials, can solve the problems of easy creases, cracks, poor flexibility, high brittleness, etc., and achieve the effects of short drying time, high production efficiency and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

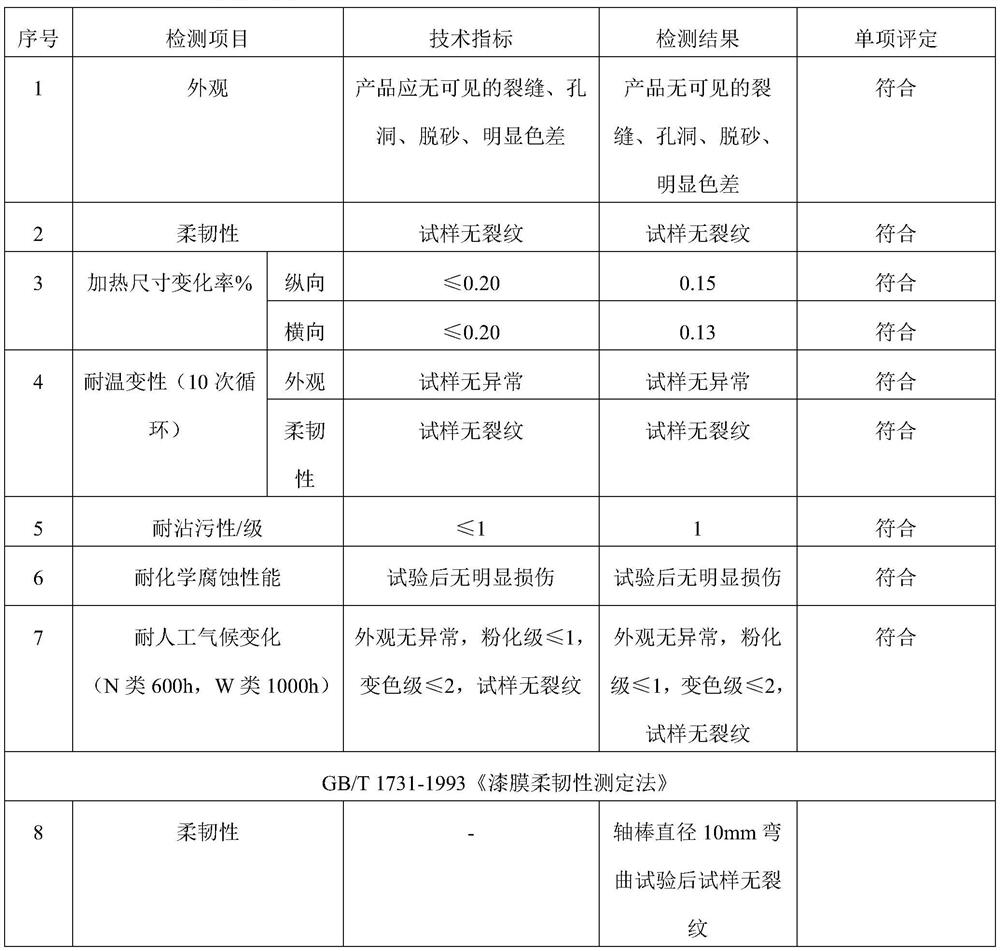

Examples

Embodiment 1

[0031] A flexible imitation stone veneer sheet, including aggregate and component A and component B with a volume ratio of 105:3, adding 60 parts by weight of aggregate to 28 parts by weight of component A, the aggregate is 100- 150 mesh natural colored sand and 50-80 mesh natural colored sand are mixed according to the mass ratio of 1:0.5;

[0032] Component A includes the following raw materials in parts by weight: 2 parts of water-soluble polyvinyl alcohol, 0.13 parts of potassium persulfate, 21 parts of distilled water, 1.8 parts of methacrylic acid, 0.1 part of styrene, 3 parts of methyl methacrylate, isooctyl acrylate 3.5 parts of ester, 0.5 part of isooctyl methacrylate, 0.5 part of acetoacetoxy ethyl methacrylate, 2.3 parts of ethylene-vinyl acetate copolymer;

[0033] Component B includes the following raw materials in parts by weight: 2 parts of zinc acetate, 2 parts of ammonia water, 0.6 parts of water-soluble polyvinyl alcohol and 60 parts of distilled water, and t...

Embodiment 2

[0041] A flexible imitation stone veneer sheet, including aggregate and component A and component B with a volume ratio of 90:3, adding 70 parts by weight of aggregate to 30 parts by weight of component A, and the aggregate is 100- 150 mesh natural colored sand and 50-80 mesh natural colored sand are mixed according to the mass ratio of 1:0.1;

[0042] Component A includes the following raw materials in parts by weight: 3 parts of water-soluble polyvinyl alcohol, 0.23 parts of potassium persulfate, 15 parts of distilled water, 0.8 parts of methacrylic acid, 0.5 parts of styrene, 2 parts of methyl methacrylate, isooctyl acrylate 2 parts of ester, 4 parts of isooctyl methacrylate, 0.3 part of acetoacetoxy ethyl methacrylate, 1.8 parts of ethylene-vinyl acetate copolymer;

[0043] Component B includes the following raw materials in parts by weight: 4 parts of zinc acetate, 1.5 parts of ammonia water, 0.1 part of water-soluble polyvinyl alcohol and 100 parts of distilled water, an...

Embodiment 3

[0051] A flexible imitation stone veneer sheet, including aggregate and component A and component B with a volume ratio of 100:3, adding 80 parts by weight of aggregate to 25 parts by weight of component A, and the aggregate is 100- 150 mesh natural colored sand and 50-80 mesh natural colored sand are mixed according to the mass ratio of 1:0.3;

[0052] Component A includes the following raw materials in parts by weight: 1 part of water-soluble polyvinyl alcohol, 0.33 parts of potassium persulfate, 16 parts of distilled water, 2.8 parts of methacrylic acid, 0.5 parts of styrene, 2 parts of methyl methacrylate, isooctyl acrylate 2 parts of ester, 4 parts of isooctyl methacrylate, 0.3 part of acetoacetoxy ethyl methacrylate, 1.8 parts of ethylene-vinyl acetate copolymer;

[0053] Component B includes the following raw materials in parts by weight: 4 parts of zinc acetate, 1.5 parts of ammonia water, 0.1 part of water-soluble polyvinyl alcohol and 100 parts of distilled water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com