Ultraviolet-assisted ultrasonic coupling electrocatalytic oxidation water treatment system and water treatment method

A technology of electrocatalytic oxidation and water treatment system, which is applied in the field of ultraviolet-assisted ultrasonic coupled electrocatalytic oxidation water treatment system and water treatment, which can solve the problems of low degradation efficiency and achieve high catalytic activity, excellent electrical conductivity and high corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

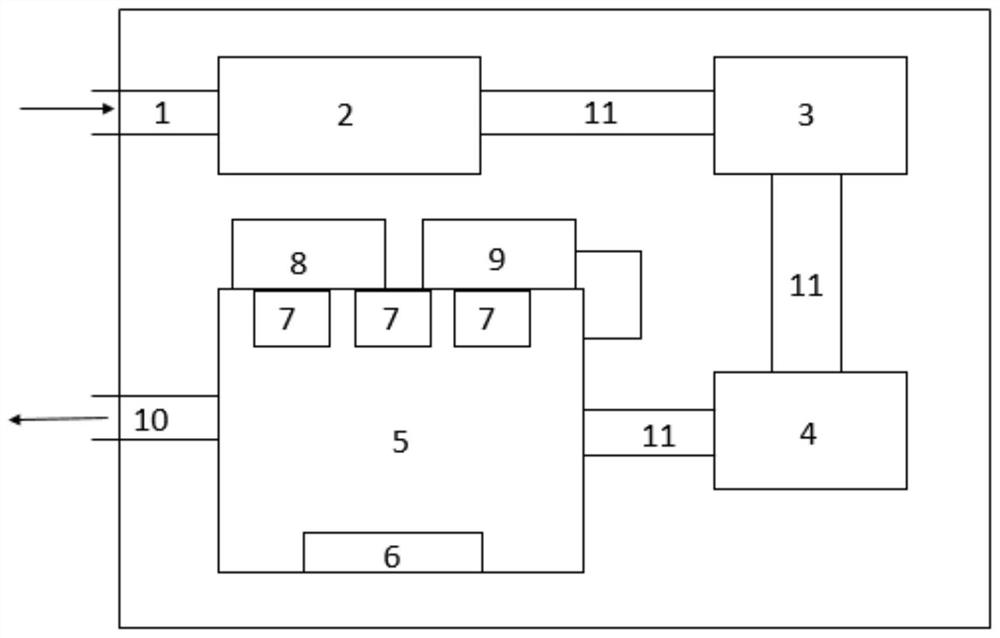

[0060] Such as figure 1 As shown, a UV-assisted ultrasonic coupling electrocatalytic oxidation water treatment system includes a pH adjustment tank 2, a particle filter module 3, the output of the pH adjustment tank 2 is connected to the particle filter module, and the outlet of the particle filter module 3 is connected to the microbial desalination Module 4, the outlet of microbial desalination module 4 is connected to electrochemical degradation module 5,

[0061] Among them, the pH adjustment pool 2 is used to adjust the pH value of the water. According to the water quality, the pH value of the water is adjusted to 6-8 by inputting lye or acid;

[0062] Wherein, the particle filter module 3 is used to filter the water after adjusting the pH value; the water with the adjusted pH value is transported to the particle filter module 3 by an automatic pump, and is filtered and separated by the filter material in the particle filter module 3, and the obtained filtrate ( The filte...

Embodiment 2

[0074] Other conditions are the same as in Example 1, except that the anodes used are two sets of flat plate electrodes parallel to each other but not in contact with each other, which are respectively placed at the left and right ends of the cathode, with a distance of about 1 cm from the cathode. Use the above system to degrade the same landfill leachate, and apply the same average current of 1.5A. As the degradation time increases, the color of the water changes from dark to light, and finally close to clarity. The specific water sample with the degradation time is shown in the figure figure 2 . After 18 hours of degradation, the water body is basically transparent and clear, and its COD removal rate reaches 98.66%.

Embodiment 3

[0076] Other conditions are different from Example 1, except that the substrate of the boron-doped diamond electrode material is porous TiC-Cr material. The above-mentioned system is also used to degrade the chemical wastewater of a certain factory. The average current is 1.5A, and the color of the water gradually becomes lighter. After 22 hours The degraded water gradually became clearer, and the COD removal rate was found to be 97.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com