Vinyl chloride polymer and method for preparing same

A vinyl chloride polymer and vinyl chloride polymerization technology, applied in the field of vinyl chloride polymer and its preparation, can solve the problems of low polymerization productivity, fish eyes and deterioration of initial coloring performance, and achieve low melt viscosity, fish eyes quality and The effect of improving the quality of initial coloring performance and shortening the polymerization reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A method of preparing a vinyl chloride polymer according to an embodiment of the present invention may include stirring the above-prepared reaction mixture, and suspension polymerization may be performed by stirring.

[0061] In addition, if necessary, the method for preparing vinyl chloride polymer according to one embodiment of the present invention may also include sodium bicarbonate (NaHCO 3 ), sodium borate (Na 2 B 4 o 7 ), disodium hydrogen phosphate (Na 2 HPO 4 ), sodium carbonate (Na 2 CO 3 ), Potassium dihydrogen phosphate (KH 2 PO 4 ), ammonium hydroxide (NH 4 OH), potassium tartrate (KHC 4 h 4 o 6 ), potassium hydrogen phthalate (KHC 8 h 4 o 4 ) and calcium hydroxide (Ca(OH) 2 ) in any one or a mixture of two or more as a hydrogen ion concentration control agent.

[0062] In addition, the method for preparing a vinyl chloride polymer according to one embodiment of the present invention may further include diallyl maleate (DAM), diallyl phthala...

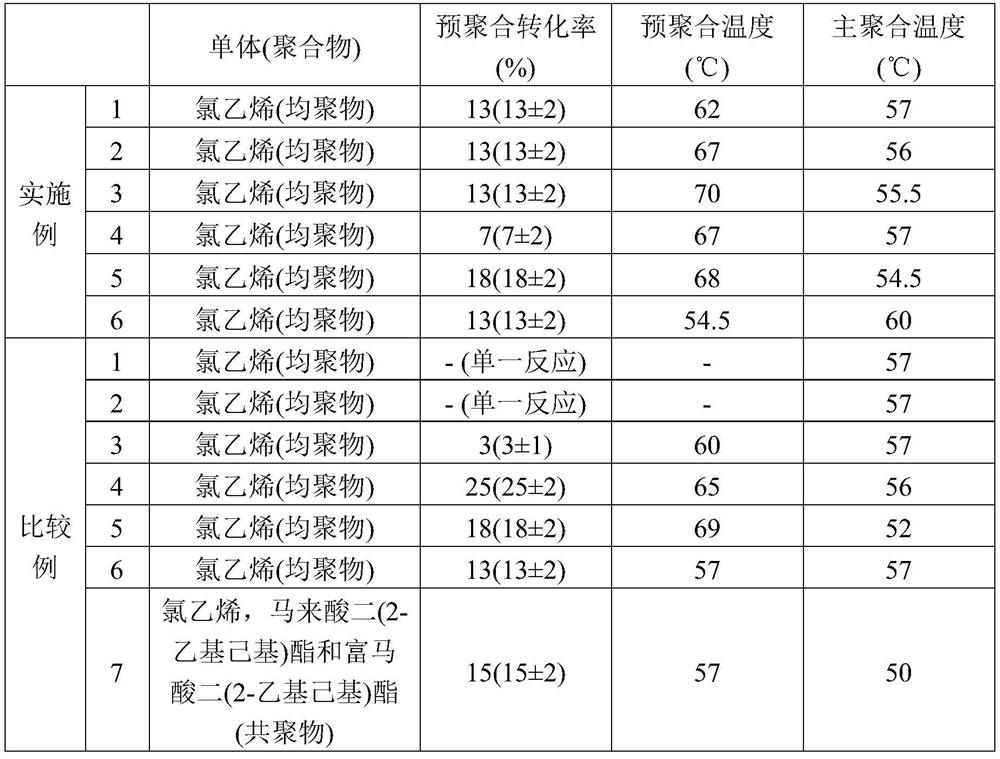

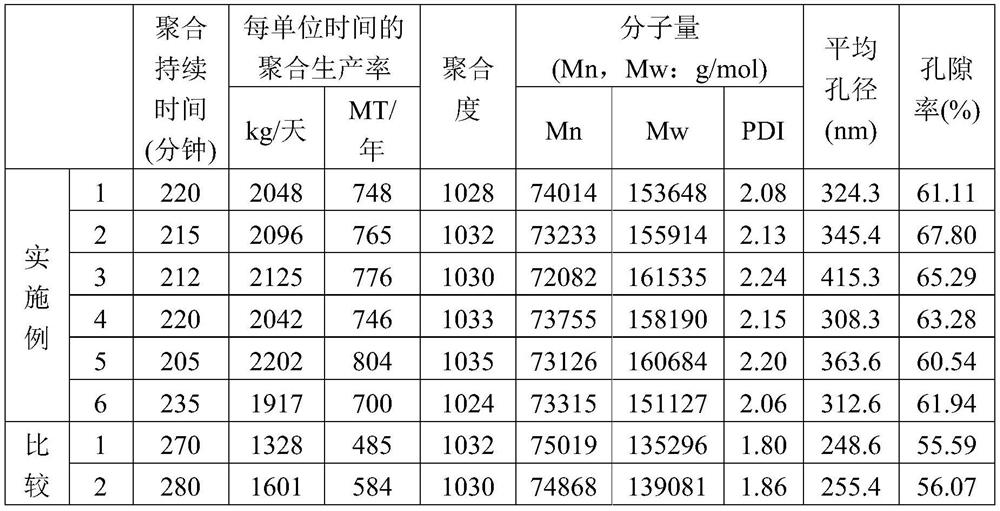

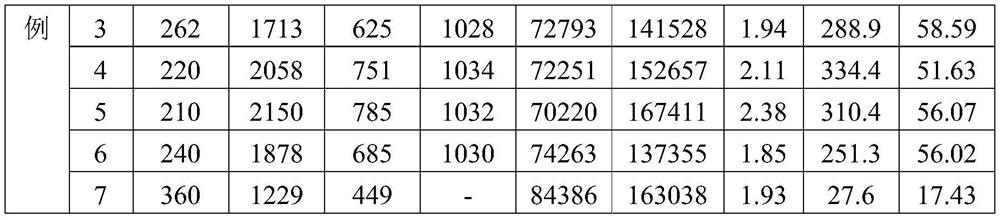

Embodiment 1

[0082] The internal volume is 0.2m 3 90kg of deionized water, 45g of hydroxy-dimethylbutyl peroxide, 60g of hydration degree of 80% and a viscosity of 30cps in a 4% aqueous solution at room temperature were introduced into the reactor (pre-polymerization reactor) Polyvinyl alcohol, 40 g of polyvinyl alcohol with a hydration degree of 40% and a viscosity of 20 cps in a 4% aqueous solution at room temperature. After the vacuum was applied, 75 kg of vinyl chloride monomer was introduced into the reactor, and the polymerization temperature was raised to 62° C. to perform a polymerization reaction. Afterwards, when the polymerization conversion rate reaches 13% (13±2%), all the prepared vinyl chloride polymerization seeds and unreacted monomers are transferred to the main polymerization reactor. At this time, the polymerization conversion was measured by gas chromatography using a butane tracer. Under predetermined polymerization conditions, whenever each polymerization condition...

Embodiment 2

[0086] In addition to raising the polymerization temperature of the pre-polymerization reactor to 67°C for polymerization, and controlling the polymerization temperature of the main polymerization reactor to 56°C for polymerization, then when the pressure of the polymerization reactor reaches 6.3kgf / cm 2 (when the polymerization conversion rate was 84% (84±2%)), except that the polymerization reaction was terminated, a vinyl chloride polymer was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com