Working electrolyte of aluminum electrolytic capacitor with voltage lower than 63V

An aluminum electrolytic capacitor and electrolyte technology, applied in the field of capacitors, can solve the problems of increasing the flash voltage of the electrolyte, failing to meet the requirements of small size, and high initial electrical characteristics of the capacitor, so as to achieve favorable capacity performance, satisfactory conductivity, and characteristics Effect with little deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

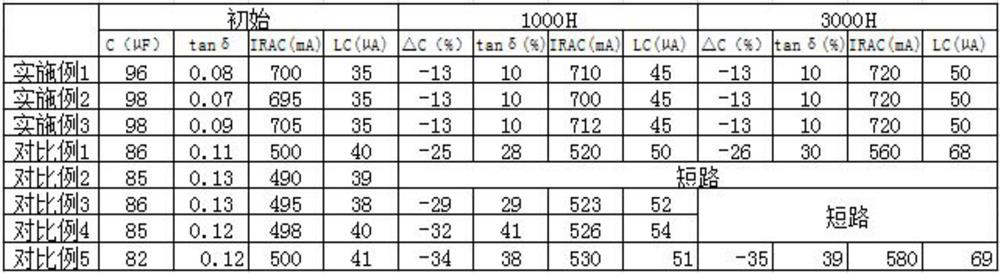

Examples

preparation example Construction

[0034] A method for preparing a working electrolyte of an aluminum electrolytic capacitor with a voltage lower than 63V, wherein the preparation of the working electrolyte of an aluminum electrolytic capacitor lower than 63V comprises the following steps:

[0035] S1. After mixing the main solvent and the auxiliary solvent, heat it to 100-125°C, add the solute, and keep it warm for 5-20 minutes to obtain a mixed solution;

[0036] S2. Under the condition that the temperature is 100-110°C, add a flash voltage booster to the mixed solution until dissolved, heat to 125-135°C, and keep warm for 10-40 minutes;

[0037] S3, after adding all the components of the electrolyte, stir evenly, lower the temperature to 85-100° C., keep the temperature for 10-30 min, and cool to obtain the electrolyte.

Embodiment 1

[0039] A working electrolyte for an aluminum electrolytic capacitor with a voltage lower than 63V. The working electrolyte for an aluminum electrolytic capacitor with a voltage lower than 63V includes the following components in parts by mass: 70 parts of a main solvent, 15 parts of an auxiliary solvent, and 18 parts of a solute , 5 parts of flash voltage booster, 0.8 part of waterproof mixture, described waterproof mixture is 1 part of 8-hydroxyquinoline, 0.8 part of 3,5-dihydroxybenzoic acid, 3 parts of phosphoric acid, 2 parts of polyphosphoric acid, 1 part of ten A mixture of dialkyl phosphate and 0.5 part cetyl phosphate.

[0040] The main solvent is ethylene glycol. Described auxiliary solvent comprises deionized water and ethylene glycol methyl ether, ethylene glycol ether.

[0041] Described solute comprises dimer acid salt, sebacic acid, adipic acid, benzoic acid benzyl ester;

[0042] The flash voltage booster includes nano-silica dispersant, amorphous copper nanop...

Embodiment 2

[0049] A working electrolyte for an aluminum electrolytic capacitor with a voltage lower than 63V. The working electrolyte for an aluminum electrolytic capacitor with a voltage lower than 63V includes the following components in parts by mass: 60 parts of a main solvent, 10 parts of an auxiliary solvent, and 10 parts of a solute , 4 parts of flash voltage booster, 0.2 part of waterproof mixture, described waterproof mixture is 3 parts of 8-hydroxyquinoline, 1 part of 3,5-dihydroxybenzoic acid, 0.5 part of phosphoric acid, 0.8 part of polyphosphoric acid, 1 part of ten A mixture of dialkyl phosphate and 0.6 part cetyl phosphate.

[0050] The main solvent is ethylene glycol. Described auxiliary solvent comprises deionized water and ethylene glycol ethyl ether, ethylene glycol butyl ether.

[0051] Described solute comprises dimer salt, sebacic acid, adipic acid, azelaic acid, dodecanedioic acid, benzoic acid;

[0052] The flash voltage booster includes nano-silica dispersant, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com