Organic material decomposing agent and preparation method thereof

A technology of organic material and decomposing agent, applied in the field of agricultural production, can solve the problems of agricultural non-point source pollution, soil structure damage, nutrient ratio imbalance, etc., and achieve the effects of high enzyme activity, strong environmental adaptability and large number of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Clostridium butyricum, Saccharomyces cerevisiae, Lactobacillus plantarum, and Bacillus subtilis were carried out in liquid fermentation, and the single-species fermentation liquid was mixed evenly according to the weight ratio of 15:20:15:40 to make a composite liquid bacterial strain (the butyric acid The number of live bacteria of Clostridium species ≥ 10 9 cfu / mL, viable count of Saccharomyces cerevisiae ≥10 9 cfu / mL, the number of live bacteria of Lactobacillus plantarum and Bacillus subtilis ≥10 8 cfu / mL).

[0042] Mix 60 parts of rice husk powder, 20 parts of bran, 15 parts of corn flour, and 15 parts of soybean meal in parts by weight to form a solid medium; dissolve 5 parts of the compound liquid bacteria in water and add to the solid medium, mix Uniform; add water to the weight ratio of water to material 1:2.

[0043]Put the inoculated material into the woven bag and put it into the fermentation room for fermentation.

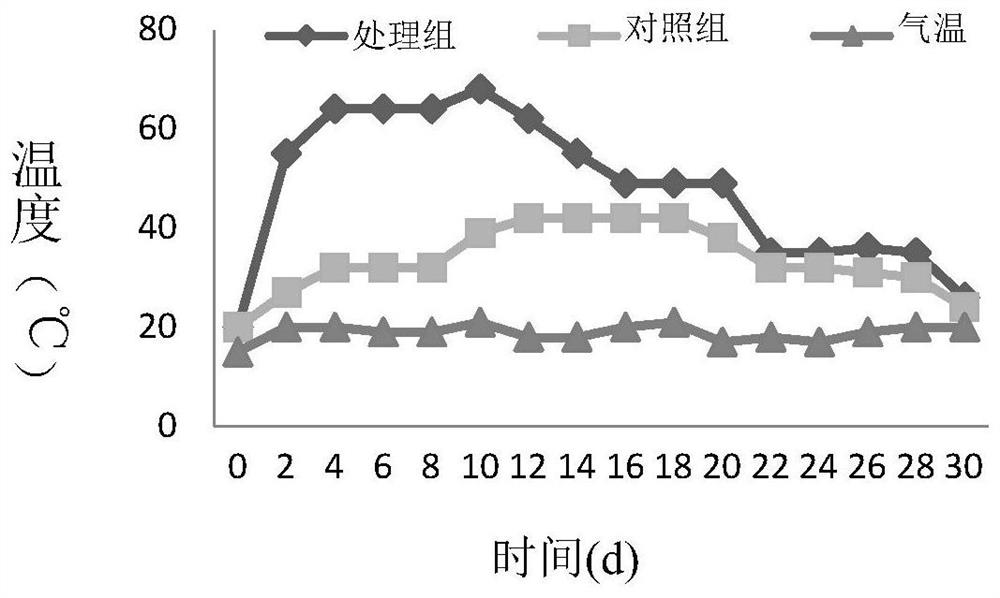

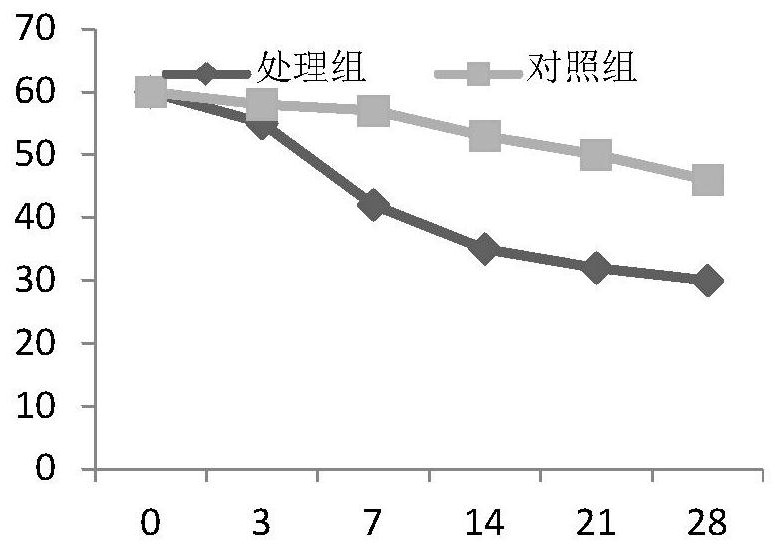

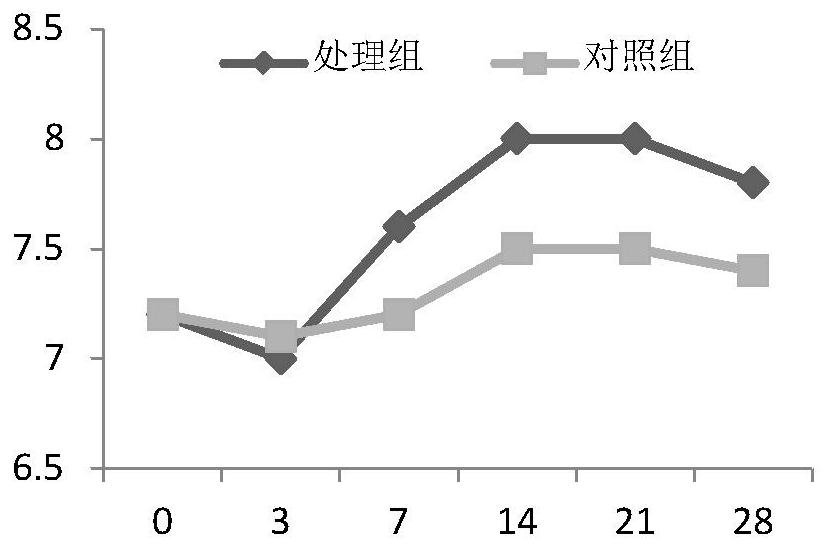

[0044] The initial fermentation condi...

Embodiment 2

[0048] Clostridium butyricum, Saccharomyces cerevisiae, Lactobacillus plantarum, and Bacillus subtilis were carried out in liquid fermentation, and the single-species fermentation liquid was mixed evenly according to the weight ratio of 15:20:15:40 to make a composite liquid bacterial strain (the butyric acid The number of live bacteria of Clostridium species ≥ 10 9 cfu / mL, viable count of Saccharomyces cerevisiae ≥10 9 cfu / mL, the number of live bacteria of Lactobacillus plantarum and Bacillus subtilis ≥10 8 cfu / mL).

[0049] Mix 65 parts of rice husk powder, 20 parts of bran, 10 parts of corn flour, and 10 parts of soybean meal to form a solid medium; dissolve 5 parts of the compound liquid bacteria in water and add it to the solid medium, and mix well; replenish water To water material weight ratio 2:3.

[0050] Put the inoculated material into the woven bag and put it into the fermentation room for fermentation.

[0051] The initial fermentation conditions are as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bacteria | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com