A Laser Scanning-Based Wire Filling Welding Method for Thick Plates with Narrow Gap

A technology of laser scanning and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unfused interlayers and unfused side walls, achieve sufficient heat input, increase area, and reduce pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

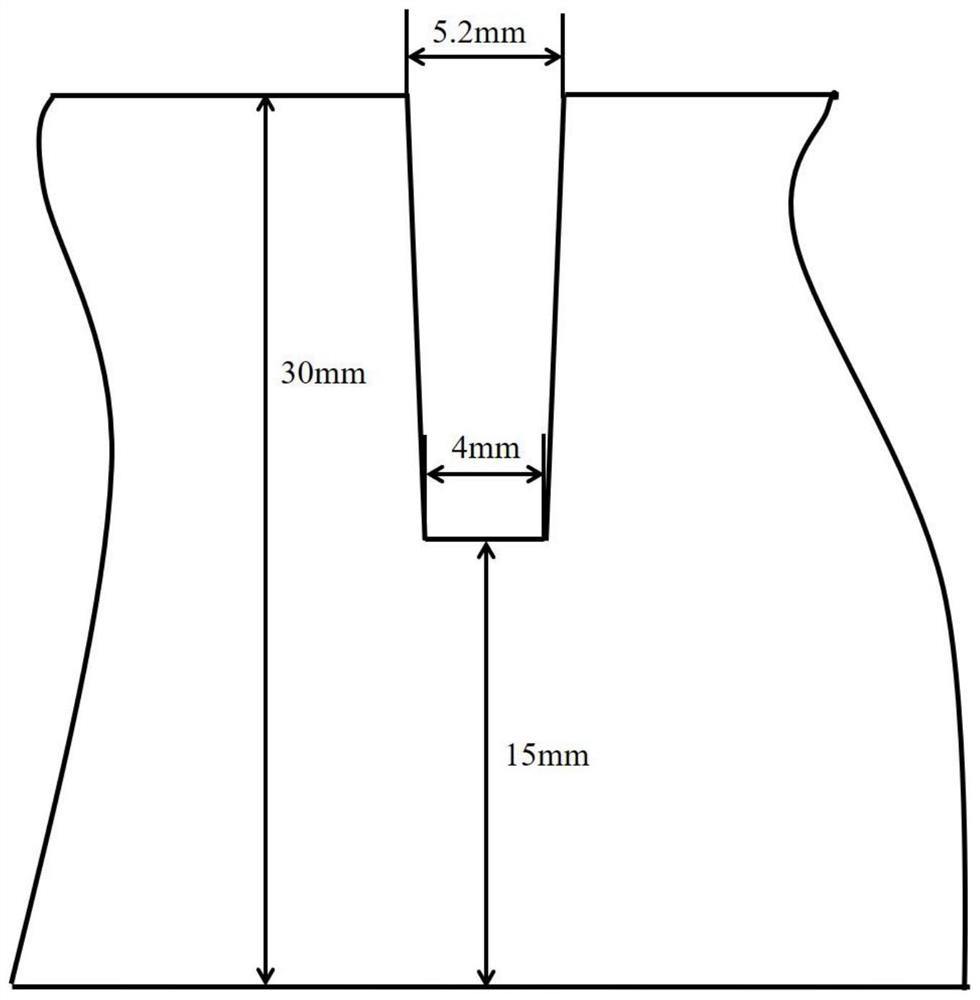

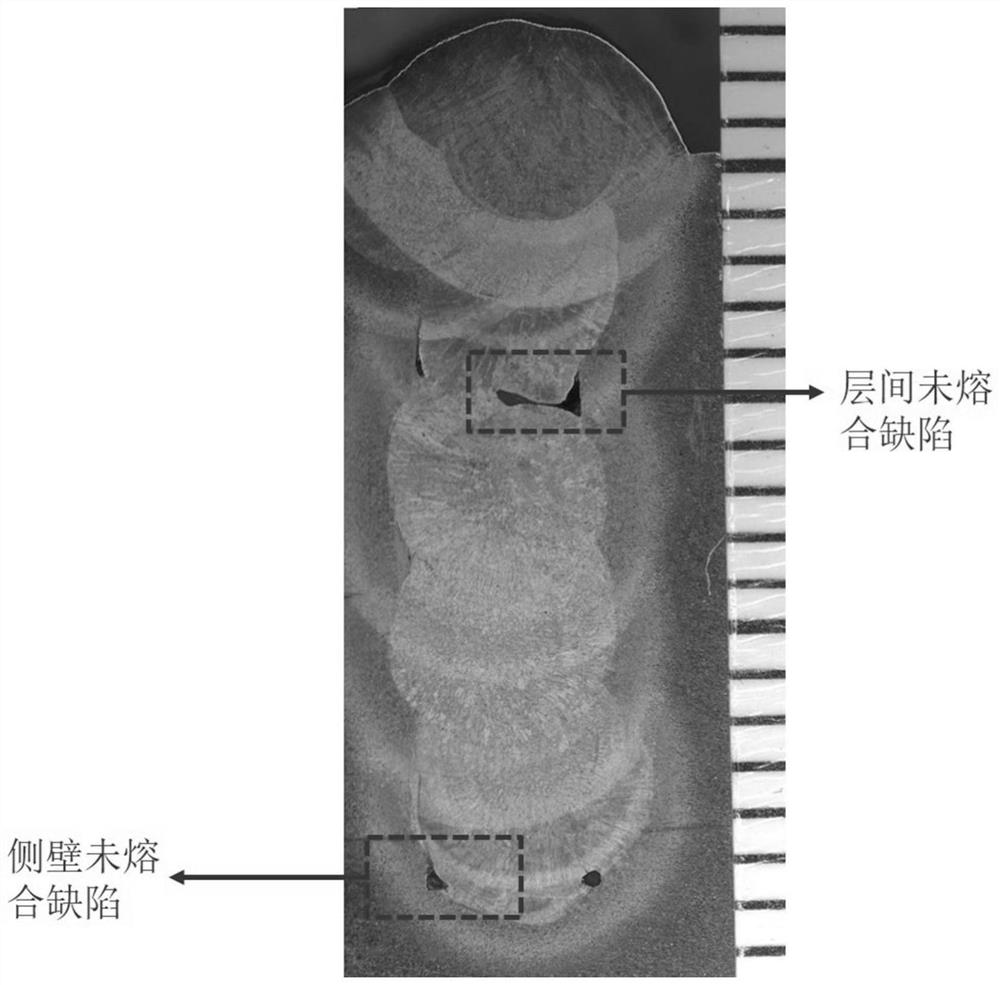

[0055] In this embodiment, the laser does not scan the narrow gap filler wire to weld the Q235 test plate, and the groove form of the test plate is as follows figure 1 As shown, specifically, the Q235 test plate is first polished with sandpaper to remove oxides and impurities on the surface of the Q235 test plate to reveal the metallic luster, and then use acetone to scrub the Q235 test plate; Argon gas with a purity of 99.99% is introduced into the welding gas protection device, and the gas flow rate is 25L / min; adjust the laser welding head so that the angle between the axis of the laser beam emitted by the laser welding head and the vertical direction is 5°; Wire nozzle, so that the angle between the wire feeding nozzle and the plane of the test plate is 45°; turn on the laser, adjust the distance between the light wires to 0mm, and perform single-channel single-layer wire-filled welding along the welding direction, the laser power is 4000W, and the defocus is + 45mm, the w...

Embodiment B

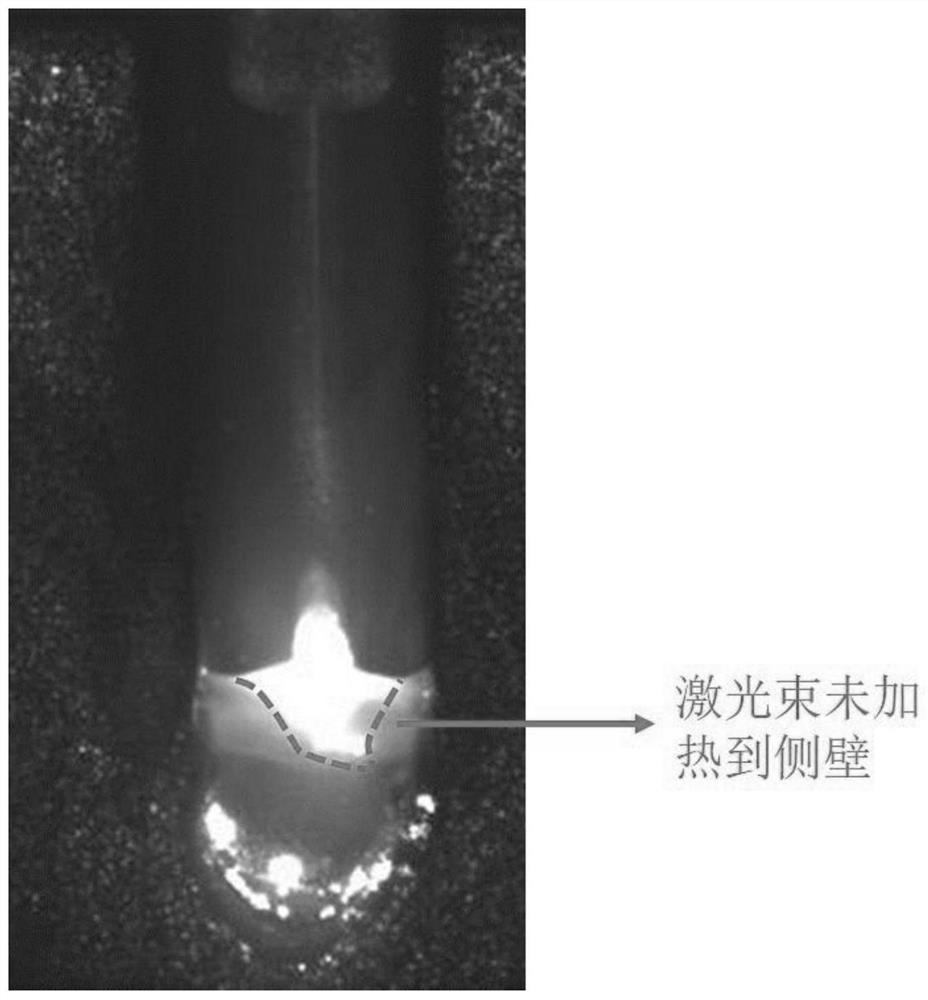

[0057] In this embodiment, the laser scanning narrow gap filler wire welds the Q235 test plate, and the groove form of the test plate is as follows figure 1 As shown, specifically, the Q235 test plate is first polished with sandpaper to remove oxides and impurities on the surface of the Q235 test plate to reveal the metallic luster, and then use acetone to scrub the Q235 test plate; Argon gas with a purity of 99.99% is introduced into the welding gas protection device, and the gas flow rate is 25L / min; adjust the laser swing welding head so that the angle between the axis of the laser beam emitted by the laser swing welding head and the vertical direction is 5°; at the same time Adjust the wire feeding nozzle so that the angle between the wire feeding nozzle and the plane of the test plate is 45°; turn on the laser and scan the laser beam emitted by the laser scanning welding head to perform five-level scanning pre-scanning on the groove area of the low carbon steel test plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com