Novel ultrathin battery and preparation process thereof

A battery, ultra-thin technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of large battery production consumables, complex production process, insufficient capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

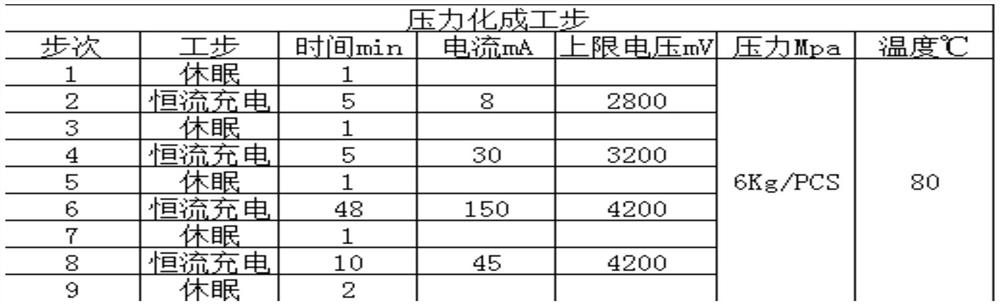

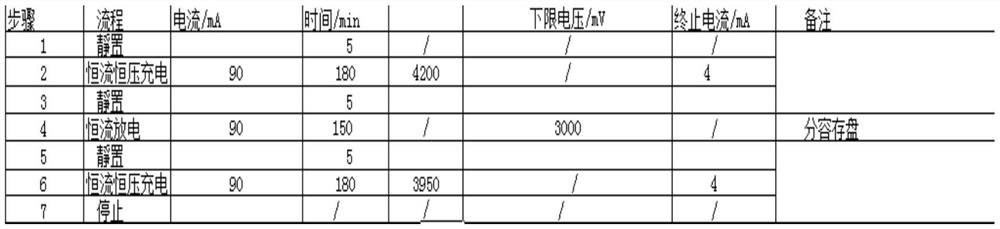

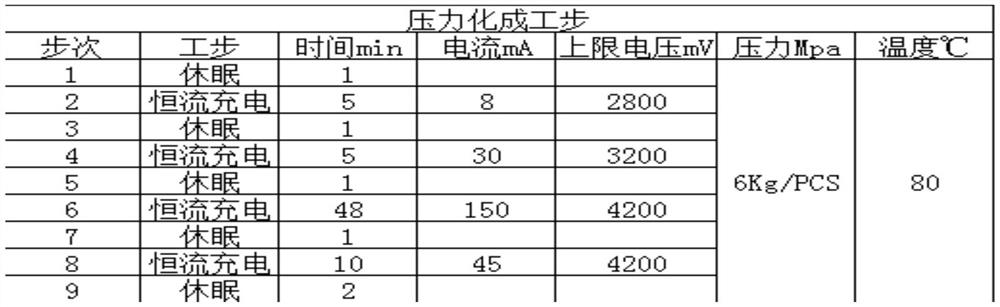

[0105] A new type of ultra-thin battery, including the positive electrode base material of the battery, the negative electrode base material, the positive electrode particle material, the negative electrode particle material, the separator, the positive electrode ear and the negative electrode ear of the battery, and the positive electrode particle material and the negative electrode particle material are respectively coated on the positive electrode substrate and the negative base material, a separator is used between the positive base material and the negative base material. Granular materials, separators, positive and negative tabs are packaged with aluminum-plastic film and filled with electrolyte, and activated and shaped by high-temperature pressure formation.

[0106] The positive electrode substrate is 10 μm aluminum foil, the negative electrode substrate is 6 μm copper foil, the positive electrode particle material / negative electrode particle material is respectively b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com