High-temperature plateau mountain vehicle hub bearing lubricating grease and preparation method thereof

A technology for wheel hub bearing and grease, which is applied to the field of high temperature plateau mountain vehicle wheel hub bearing grease and its preparation, can solve the problems of low grease dropping point, grease loss, low performance, etc., and achieves good storage stability and good rubber. Compatibility, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

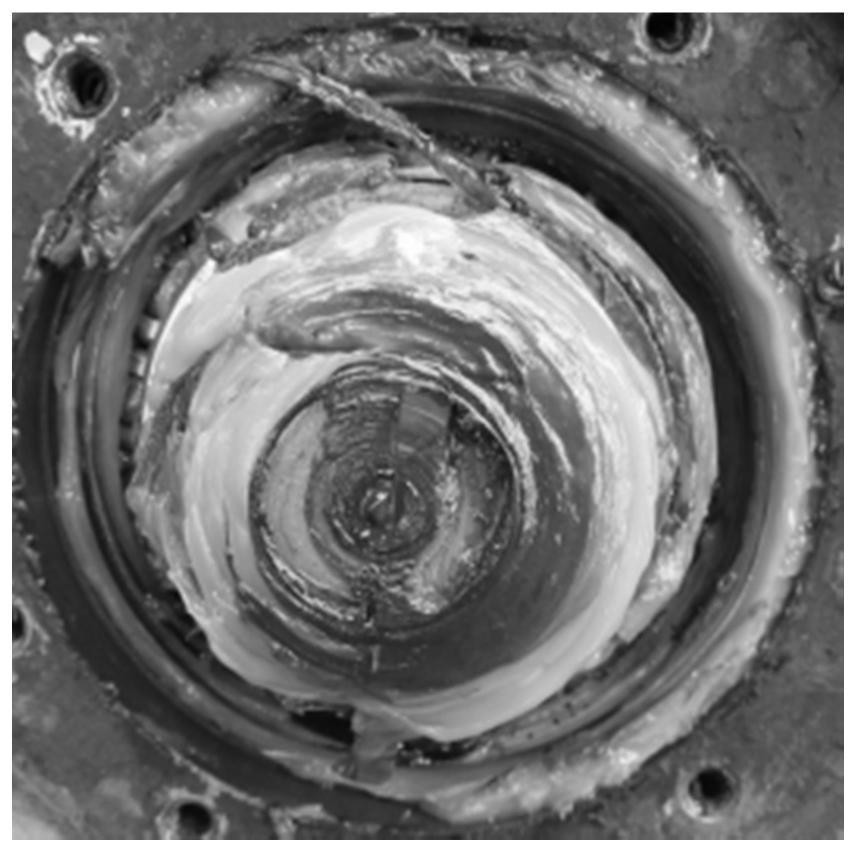

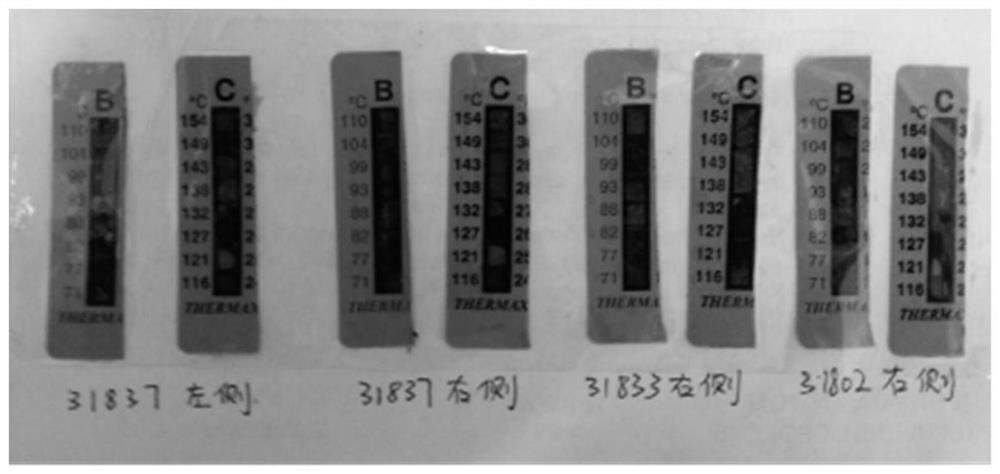

Image

Examples

Embodiment 1

[0046] This embodiment provides a (full mineral oil type) high-temperature and high-altitude mountain vehicle hub bearing lubricating grease. The components are: 85.5% base oil, 10% thickener, and 4.5% additives. The base oil is a refined paraffin-based blended lubricating oil. The thickener is a complex lithium-based thickener, the base is lithium hydroxide, the molar ratio of lithium hydroxide to water in the lye is 1:4, the high-molecular acid is 12-hydroxystearic acid, and the low-molecular acid is decane Acid, the molar ratio of 12-hydroxystearic acid to sebacic acid is 3:1. The additives are 0.5% of alkyl diphenylamine antioxidant, 0.5% of polymer liquid phenol antioxidant, 0.2% of thiocarbamate / thiophosphate antioxidant, and 0.2% of benzotriazole rust inhibitor. %, triphenyl thiophosphate extreme pressure antiwear agent 2.5%, ethylene-propylene copolymer tackifier 0.6%, the sum is 100%.

[0047] This embodiment also provides a kind of (full mineral oil type) high-temp...

Embodiment 2

[0053] This embodiment provides a (full mineral oil type) high-temperature and high-altitude mountain vehicle hub bearing lubricating grease. The components are: 79.8% of base oil, 12% of thickener, and 8.2% of additives. The base oil is refined paraffin-based mixed lubricating oil, the thickener is a complex lithium-based thickener, the alkali is lithium hydroxide, the molar ratio of lithium hydroxide to water in the lye is 1:6, and the polymer acid is 12-hydroxyl Stearic acid, the low-molecular acid is azelaic acid, and the molar ratio of 12-hydroxystearic acid to the low-molecular acid composition is 6:1. Additives include 0.8% alkyl dianiline antioxidant, 0.8% polymer liquid phenol antioxidant, 1% thiocarbamate / thiophosphate antioxidant, 0.6% barium petroleum sulfonate rust inhibitor , Thiophosphate type extreme pressure antiwear agent 4%, polyisobutylene tackifier 1%, the sum is 100%.

[0054] This embodiment also provides a kind of (all mineral oil type) high-temperatur...

Embodiment 3

[0060] This embodiment provides a (full mineral oil type) high-temperature and high-altitude mountain vehicle hub bearing lubricating grease. The components are: 79% of base oil, 12% of thickener, and 9% of additives. The base oil is refined paraffin-based mixed lubricating oil with a viscosity of 180mm at 40°C 2 / s~220mm 2 / s, viscosity greater than 15mm at 100°C 2 / s. The thickener is a complex lithium-based thickener, the base is lithium hydroxide, the molar ratio of lithium hydroxide to water in the lye is 1:2 to 1:6, the high molecular acid is 12-hydroxystearic acid, and the low molecular weight The acid is a combination of azelaic acid and sebacic acid, and the molar ratio of 12-hydroxystearic acid to the low-molecular acid composition is 1:1. Additives include 0.5% alkyl dianiline antioxidant, 0.7% polymer liquid phenol antioxidant, 1.3% thiocarbamate / thiophosphate antioxidant, 0.5% calcium petroleum sulfonate rust inhibitor , thiourethane and thiophosphate type ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com