Lubricating oil composition as well as preparation method and application thereof

A technology of lubricating oil composition and synthetic ester, which is applied in the field of lubricating oil, and can solve the problems that the anti-oxidation performance is not mentioned, the viscosity-temperature performance needs to be improved, and needs to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

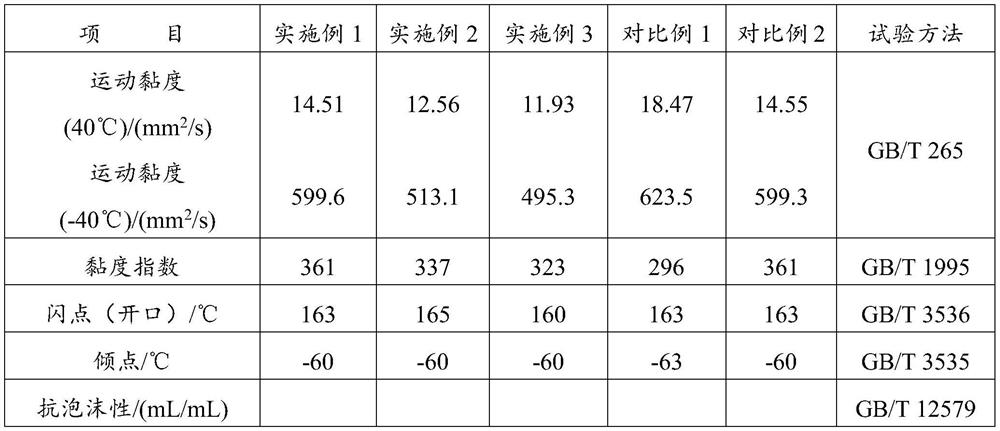

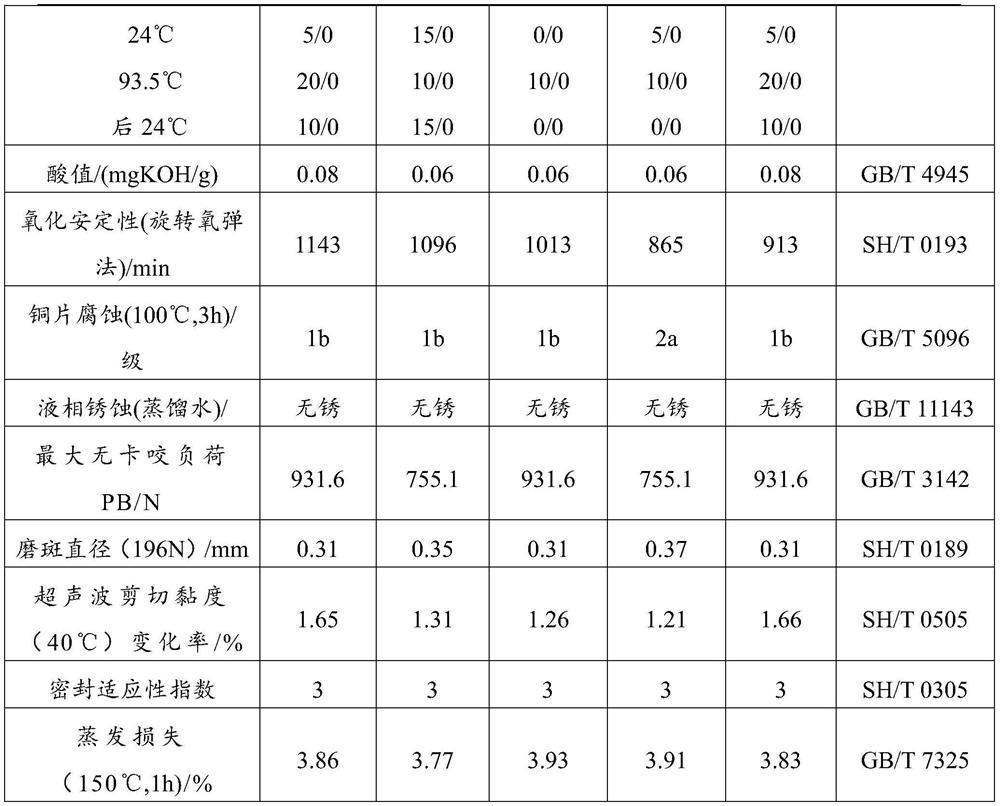

Examples

preparation example Construction

[0032] The present invention provides the preparation method of the lubricating oil composition described in the above technical solution, comprising the following steps:

[0033] The components are mixed to obtain a lubricating oil composition.

[0034] In the present invention, the mixing temperature is preferably 50˜70° C.; and the mixing time is preferably 1.5˜3 h. In the present invention, the mixing is preferably carried out under stirring conditions.

[0035] In the present invention, the mixing of the components preferably includes: improving the viscosity index of polyα-olefin synthetic oil, synthetic ester and polymethacrylate and mixing them uniformly, and then adding antioxidant, extreme pressure antiwear agent, Friction reducer, rust inhibitor and antifoam blend.

[0036] The present invention also provides the application of the lubricating oil composition described in the above technical solution or the lubricating oil composition prepared by the preparation m...

Embodiment 1

[0039] Add 19.5g diisooctyl adipate and 15.0g polymethacrylate viscosity index improver to 65.0g polyalpha-olefin synthetic oil PAO2 (100 ℃ kinematic viscosity is 1390mm 2 / s), stir for 1 hour at 60±5℃ to make it evenly mixed, then add 0.05g of 1-(3,5-di-tert-butyl-4-hydroxybenzyl)-3-methylimidazolium Fluorophosphate, 0.1g dioctyl diphenylamine, 0.05g N-phenyl-α-naphthylamine, 0.05g tricresyl phosphate, 0.05g didodecyl phosphite, 0.05g dialkyl disulfide Phosphate, 0.1g molybdenum dialkyldithiocarbamate, 0.05g low base number C22~24 alkylbenzene sulfonate calcium (base number 26.3), 0.01g polymethyl silicone oil T901 and 0.01g polyacrylate T912, stirred at 60±5° C. for 3 hours, and cooled to room temperature to obtain a lubricating oil composition.

Embodiment 2

[0041] Add 3.0g diisooctyl adipate and 11.65g polymethacrylate viscosity index improver to 85.0g polyalpha-olefin synthetic oil PAO2 (100 ℃ kinematic viscosity is 1390mm 2 / s), stir for 1 hour at 60±5℃ to make it evenly mixed, then add 0.05g of 1-(3,5-di-tert-butyl-4-hydroxybenzyl)-3-methylimidazolium Fluorophosphate, 0.05g dioctyl diphenylamine, 0.1g N-phenyl-α-naphthylamine, 0.03g tricresyl phosphate, 0.02g didodecyl phosphite, 0.09g dialkyl disulfide Molybdenum carbamate, 0.01g neutral calcium dinonylnaphthalene sulfonate, 0.0005g polymethylsilicone T901 and 0.0005g polyacrylate T912, stirred at 60±5°C for 3 hours, cooled to room temperature to obtain lubricating oil combination thing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com