Advanced treatment method for electroplating wastewater

A technology for advanced treatment of electroplating wastewater, applied in metallurgical wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problem of ineffective removal of surfactants and other organic pollutants, high treatment costs, and large footprint and other problems, to achieve the effect of high removal rate of suspended solids, improvement of removal rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

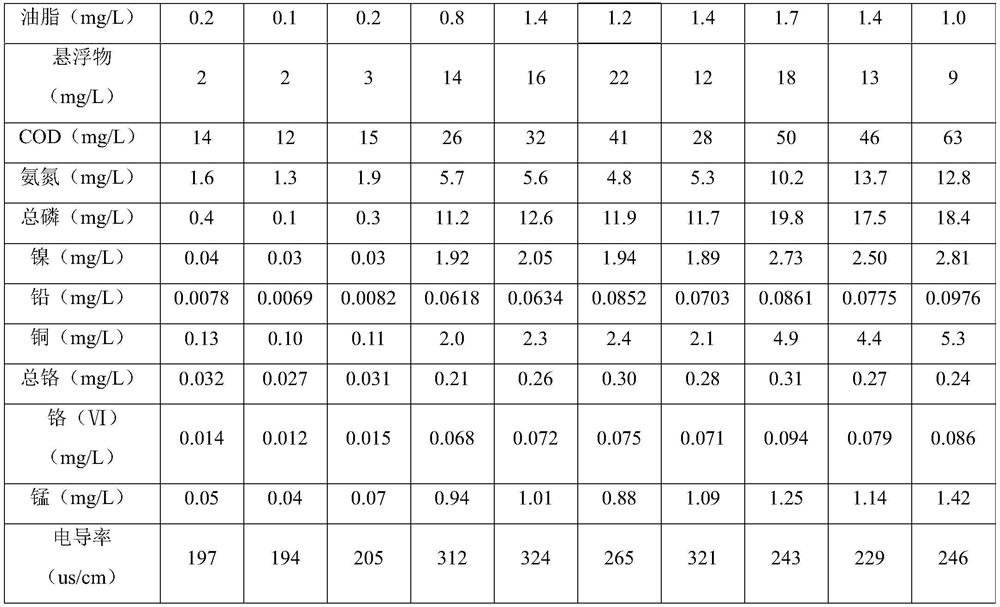

Embodiment 1

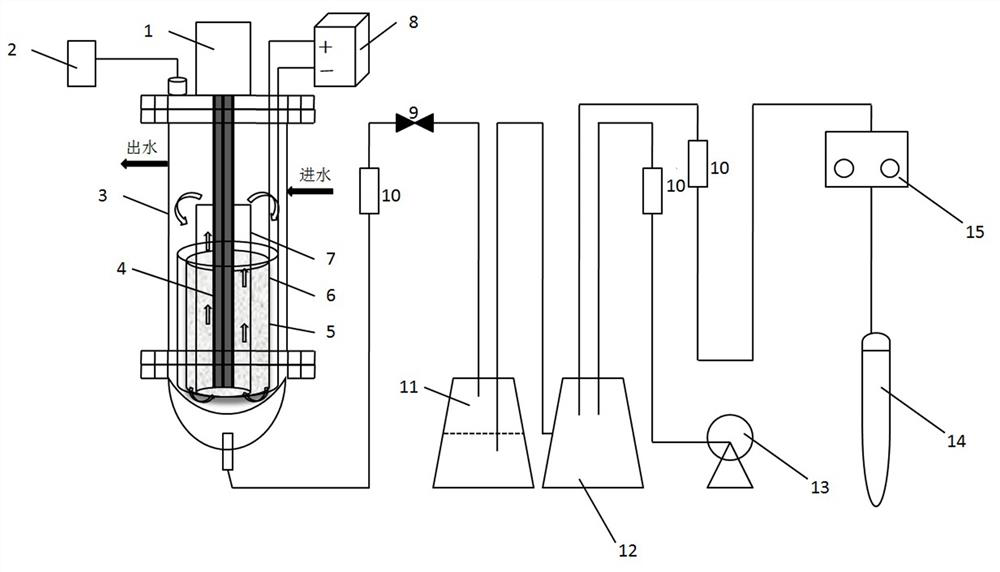

[0032] A method for advanced treatment of electroplating wastewater, comprising the following steps:

[0033] Step 1. Pretreatment: Homogenize the electroplating wastewater in the adjustment tank, then enter the pH reaction tank, adjust the pH to 4.5, and then pass it into the degreasing device, and remove the grease through the PERFECT degreasing film of the degreasing device;

[0034] Step 2, coagulation and sedimentation: the effluent of the oil removal device enters the coagulation and sedimentation tank, and the compound flocculant is added at a rate of 1.5kg / t in the stirring and coagulation area of the coagulation and sedimentation tank for reaction coagulation, and solid-liquid separation is carried out in the sedimentation area. The effluent from the coagulation sedimentation tank enters the subsequent section after passing through the microfiltration HMF membrane filter;

[0035] Step 3, electrochemical-photocatalytic-ozone synergistic treatment: the effluent from ...

Embodiment 2

[0048] Step 1. Pretreatment: Homogenize the electroplating wastewater in the adjustment tank, then enter the pH reaction tank, adjust the pH to 4.5, and then pass it into the degreasing device, and remove the grease through the PERFECT degreasing film of the degreasing device;

[0049] Step 2, coagulation and sedimentation: the effluent of the oil removal device enters the coagulation and sedimentation tank, and the compound flocculant is added at a rate of 2.0kg / t in the stirring and coagulation area of the coagulation and sedimentation tank for reaction coagulation, and solid-liquid separation is carried out in the sedimentation area. The effluent from the coagulation sedimentation tank enters the subsequent section after passing through the microfiltration HMF membrane filter;

[0050] Step 3. Electrochemical-photocatalytic-ozone synergistic treatment: the effluent from the microfiltration HMF membrane filter enters the electrochemical-photocatalytic-ozone synergistic reac...

Embodiment 3

[0063] A method for advanced treatment of electroplating wastewater, comprising the following steps:

[0064] Step 1. Pretreatment: Homogenize the electroplating wastewater in the adjustment tank, then enter the pH reaction tank, adjust the pH to 4.5, and then pass it into the degreasing device, and remove the grease through the PERFECT degreasing film of the degreasing device;

[0065]Step 2, coagulation and sedimentation: the effluent of the oil removal device enters the coagulation and sedimentation tank, and the compound flocculant is added in the stirring and coagulation area of the coagulation and sedimentation tank to react coagulation, and the solid-liquid separation is carried out in the sedimentation area, and the coagulation and sedimentation tank effluent After passing through the microfiltration HMF membrane filter, it enters the subsequent section;

[0066] Step 3. Electrochemical-photocatalytic-ozone synergistic treatment: the effluent from the microfiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com