Cigarette cooling particles and application thereof

A cigarette and particle technology, applied in the application, tobacco, e-liquid filter and other directions, can solve the problems of filter rod leakage, affecting the consumer's smoking experience, etc., to achieve sweet and sweet smoke, improve the smoking experience, raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

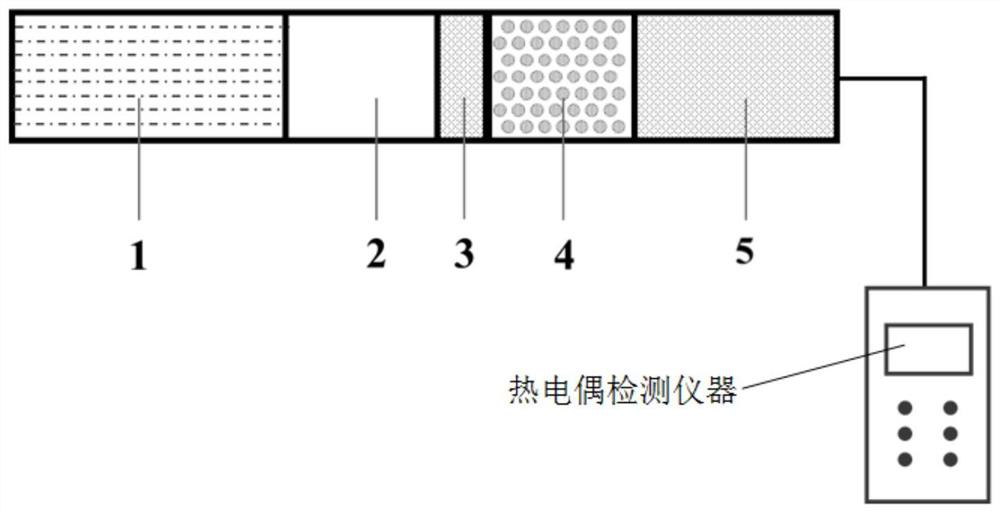

[0029] Weigh 10g of erythritol and 7.5g of polyethylene glycol 4000, heat to melt, stir for 1 hour, then cool and crystallize at room temperature for 1 hour, and then pulverize into particles of about 20 meshes to obtain the cigarette cooling particles. From its DSC curve ( figure 1 ) shows that the phase transition temperature of the cooling particles is 63.4°C, and the phase transition enthalpy is 103 J / g. Weigh 75 mg / cigarette cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. see figure 2 , the cigarette sample includes a tobacco segment 1, a hollow filter rod segment 2, a first cellulose acetate filter rod segment 3, a cooling segment 4 and a second cellulose acetate filter rod segment 5 connected in sequence from left to right, and the cooling segment 4 The cigarette temperature-lowering particles are added inside, and the added amount is 75mg / stick.

Embodiment 2

[0031] Weigh 10g of xylitol and 10g of polyethylene glycol 2000 and heat to melt, stir for 1 hour, then cool and crystallize at -20°C for 4 hours, then crush and sieve out particles of about 20 meshes to obtain the cigarette cooling particles. Weigh 100 mg / cigarette cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. The structure of the cigarette sample in this example is the same as the cigarette sample in Example 1, the only difference is that the cigarette cooling granules provided in this example are added in the cooling section, and the added amount is 100 mg / cigarette.

Embodiment 3

[0033] Weigh 10g of erythritol and 20g of polyethylene glycol 4000, heat to melt, stir for 1 hour, then cool and crystallize at room temperature for 1 hour, and then pulverize into particles of about 20 meshes to obtain the cigarette cooling particles. Weigh 150 mg / cigarette cooling particles to prepare a composite filter rod, and wrap it into the rear end of a heat-not-burn cigarette rod to obtain a cigarette sample. The structure of the cigarette sample in this example is the same as the cigarette sample in Example 1, the only difference is that the cigarette cooling granules provided in this example are added in the cooling section, and the added amount is 150 mg / cigarette.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com