Production method for flexible packaging film

A manufacturing method and flexible packaging technology, applied in the manufacturing field of the process, can solve problems such as promoting overflow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

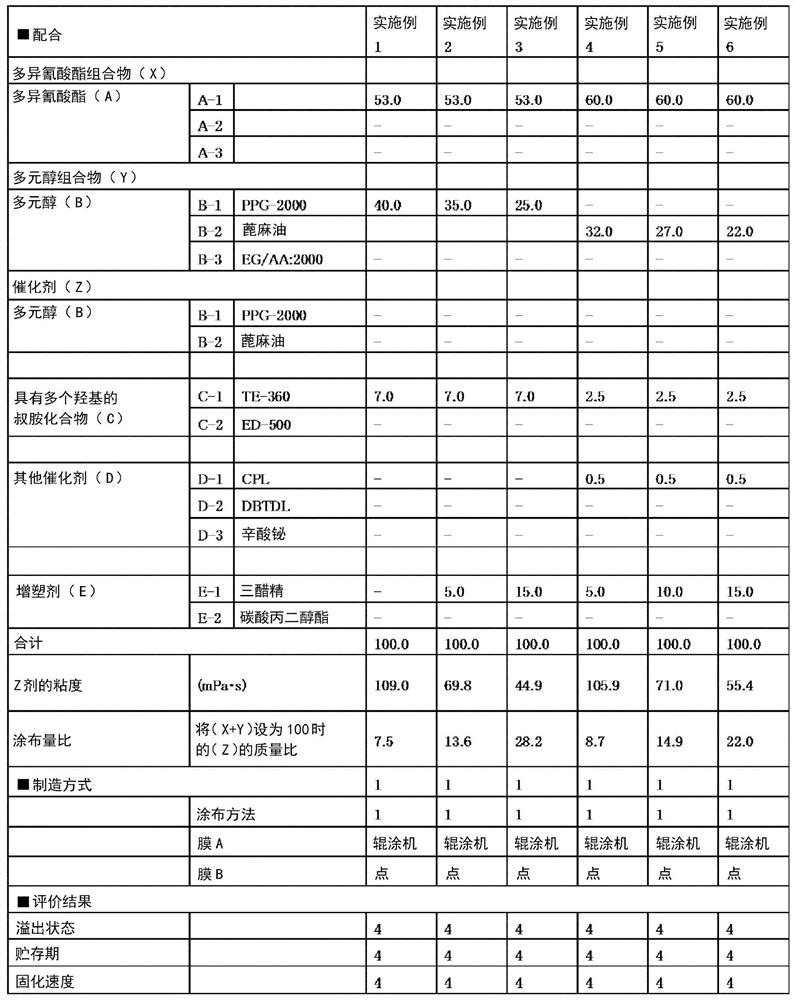

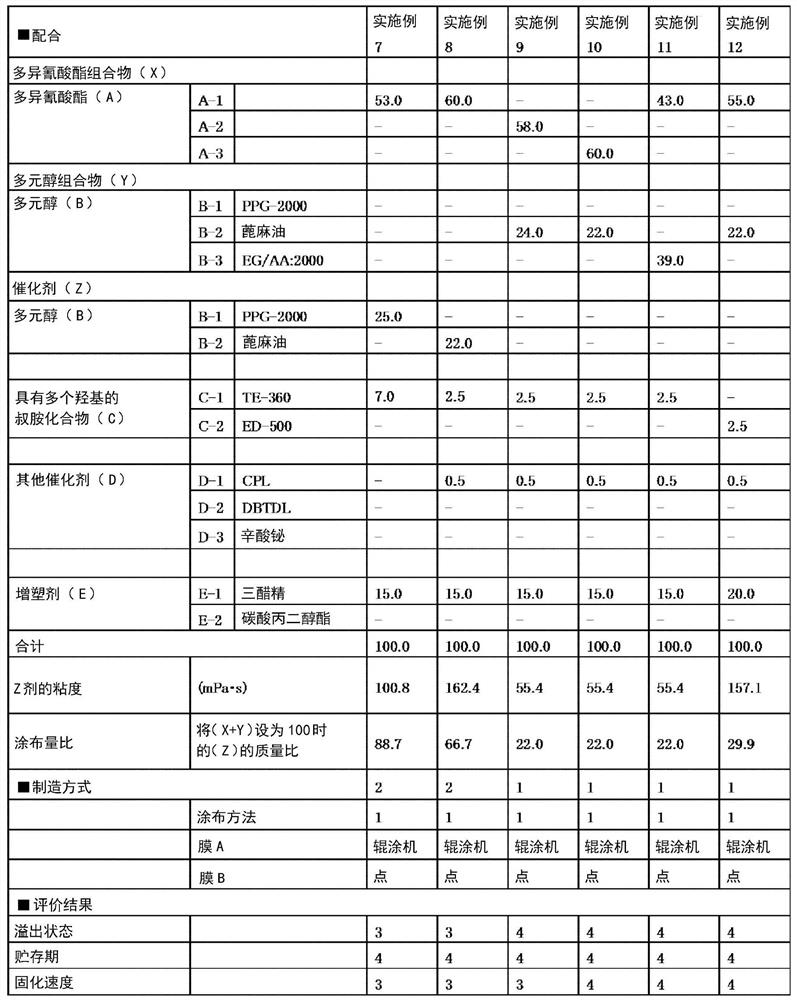

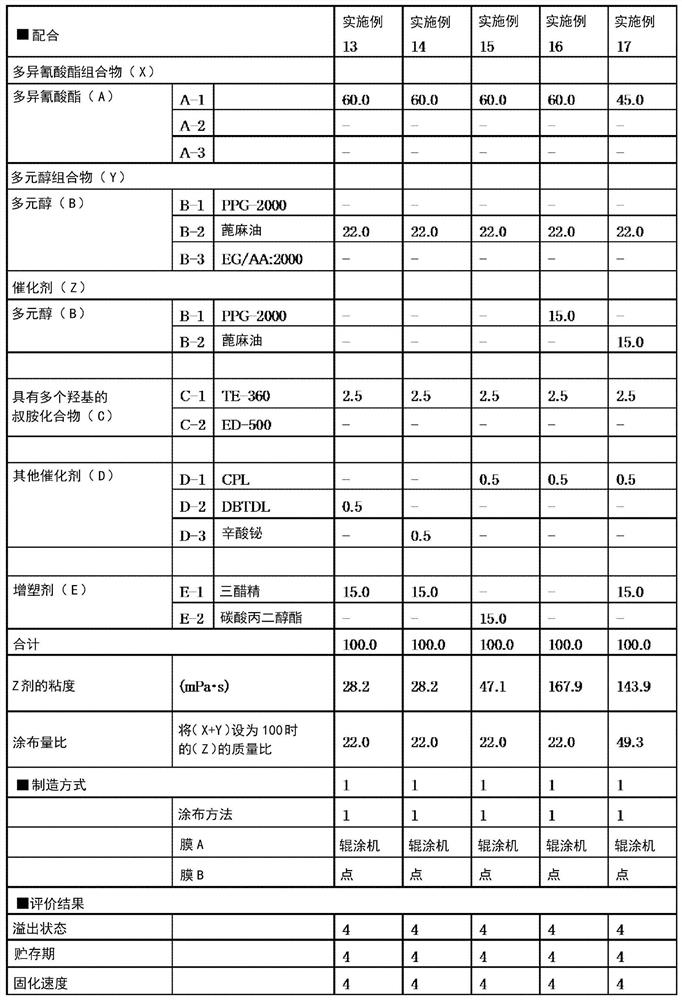

Examples

manufacture example 1

[0113] Production Example 1 [Synthesis of Polyisocyanate (A-1)]

[0114] In a flask equipped with a stirrer, a thermometer, and a nitrogen inlet tube, 17 parts of 4,4-diphenylmethane diisocyanate and 38 parts of an MDI mixture ["Lupranate MI" manufactured by BASF Corporation, 4,4'-diphenyl A mixture of methane diisocyanate / 2,4'-diphenylmethane diisocyanate (mass ratio) of 1 / 1] was put into the reaction container, stirred and heated to 80° C. under nitrogen. 11 parts of polypropylene glycol with a number average molecular weight of 400 (hereinafter abbreviated as "PPG"), 22 parts of PPG with a number average molecular weight of 1000, and 12 parts of PPG with a number average molecular weight of 2000 were added dropwise, stirring for 5- After 6 hours, the carbamation reaction was complete. The NCO group content rate of the obtained polyisocyanate was 13.8%, and the melt viscosity at 40 degreeC was 1500 mPa.s. Hereinafter, this polyisocyanate is abbreviated as "A-1".

manufacture example 2

[0115] Production Example 2 [Synthesis of Polyisocyanate (A-2)]

[0116] In a flask equipped with a stirrer, a thermometer, and a nitrogen gas introduction tube, 14 parts by mass of 4,4-methylene bis-diphenylisocyanate and 42 parts of an MDI mixture (the above-mentioned "Lupranate MI" manufactured by BASF Corporation) were charged into the reaction container. Stir and heat to 80° C. under nitrogen. 44 parts of polyester polyol resin ("POLYLITE OD-X-2376" manufactured by DIC Corporation, acid value 0.8mgKOH / g, molecular weight about 1000) was added dropwise, stirred for about 5 to 6 hours, and the carbamic acid The esterification reaction is complete. The NCO group content of the obtained polyisocyanate was 15.0%, and the melt viscosity at 40° C. was 2000 mPa·s. Hereinafter, this polyisocyanate is abbreviated as "A-2".

manufacture example 3

[0117] Production Example 3 [Synthesis of Polyisocyanate (A-3)]

[0118] In a flask equipped with a stirrer, a thermometer, and a nitrogen introduction tube, 35 parts of 4,4-diphenylmethane diisocyanate was put into a reaction container, and it heated to 80 degreeC with stirring under nitrogen. 5 parts of trifunctional PPG with a number average molecular weight of 400 (manufactured by Asahi Glass Co., Ltd. "Excenol 430"), 18 parts of PPG with a number average molecular weight of 1000, and 32 parts of PPG with a number average molecular weight of 2000 were added dropwise, stirring for 5 to 6 hours, the carbamate reaction was complete. After the reaction, 5 parts of isocyanurate body of 1,6-hexamethylene diisocyanate (manufactured by Covestro "Desmodul N3300"), 5 parts of polymerized diphenylmethane diisocyanate (manufactured by BASF " Lupranate M20S") and stirred for 30 minutes. The NCO group content of the obtained polyisocyanate was 10.0%, and the melt viscosity at 40° C. w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com