Manufacturing method of grid combined type graphic model based on magnetic principle

A production method and combined technology, which can be used in teaching models, manufacturing auxiliary devices, electrical digital data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

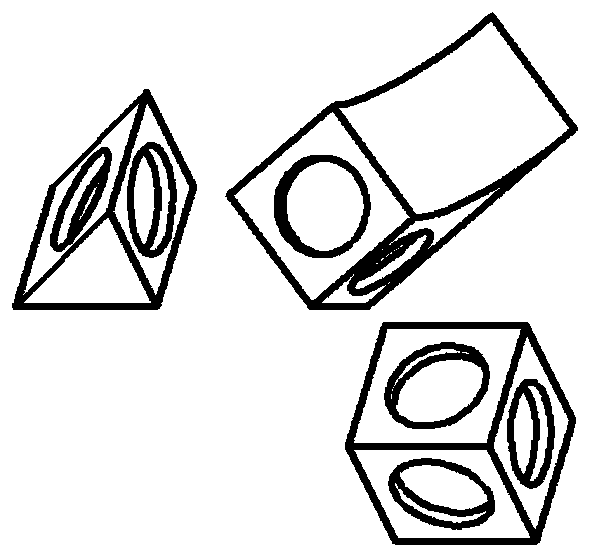

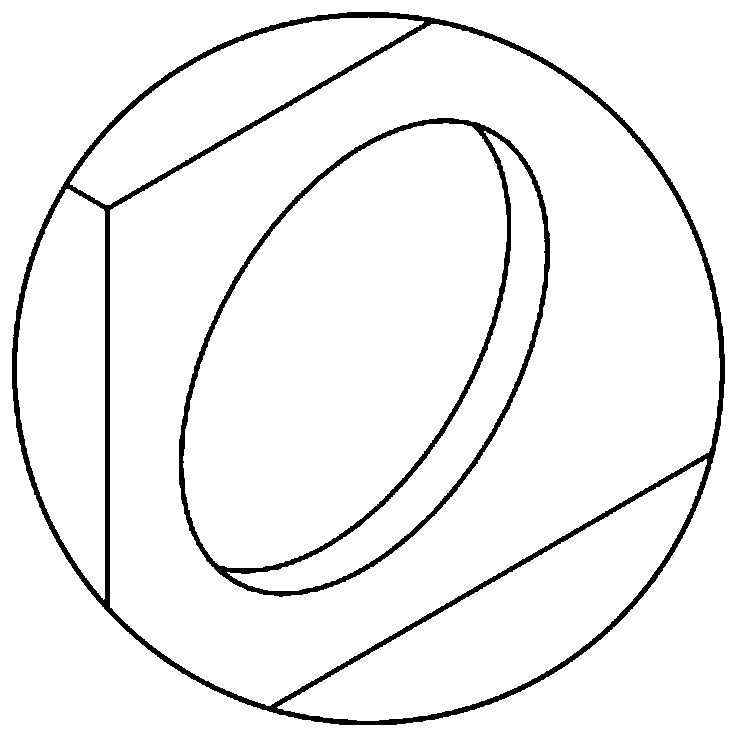

[0034] Such as Figure 1-6 As shown, a method for making a grid combined graphical model based on magnetic principles is characterized in that it comprises the following steps:

[0035] In the first step, 3D modeling of the basic unit geometry (such as figure 1 );

[0036] The second step is to 3D print and shape the basic geometry according to the model data;

[0037] The third step is the surface magnetization treatment of the unit basic geometry model;

[0038] In the fourth step, the magnetization unit body model is modularized and freely combined in a grid format to generate a new combination model;

[0039] The fifth step is to observe the formation process of the relevant intersecting lines and intersecting lines on the inner and outer surfaces of the new composite model, and analyze its view projection characteristics.

[0040] Further, the 3D modeling of the basic unit geometry is specifically:

[0041] Establish 3D models of the basic geometry of various units, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com