Water cooling tower and basalt fiber industrialization production line cooling system

A technology of basalt fiber and cooling water tower, which is applied in the direction of water shower cooler, furnace cooling device, process efficiency improvement, etc., can solve the problems of reduced cooling effect of cooling water, high humidity coefficient, low air drying coefficient, etc., and achieve extended use Longevity, improvement of convection effect, effect of suppressing expansion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

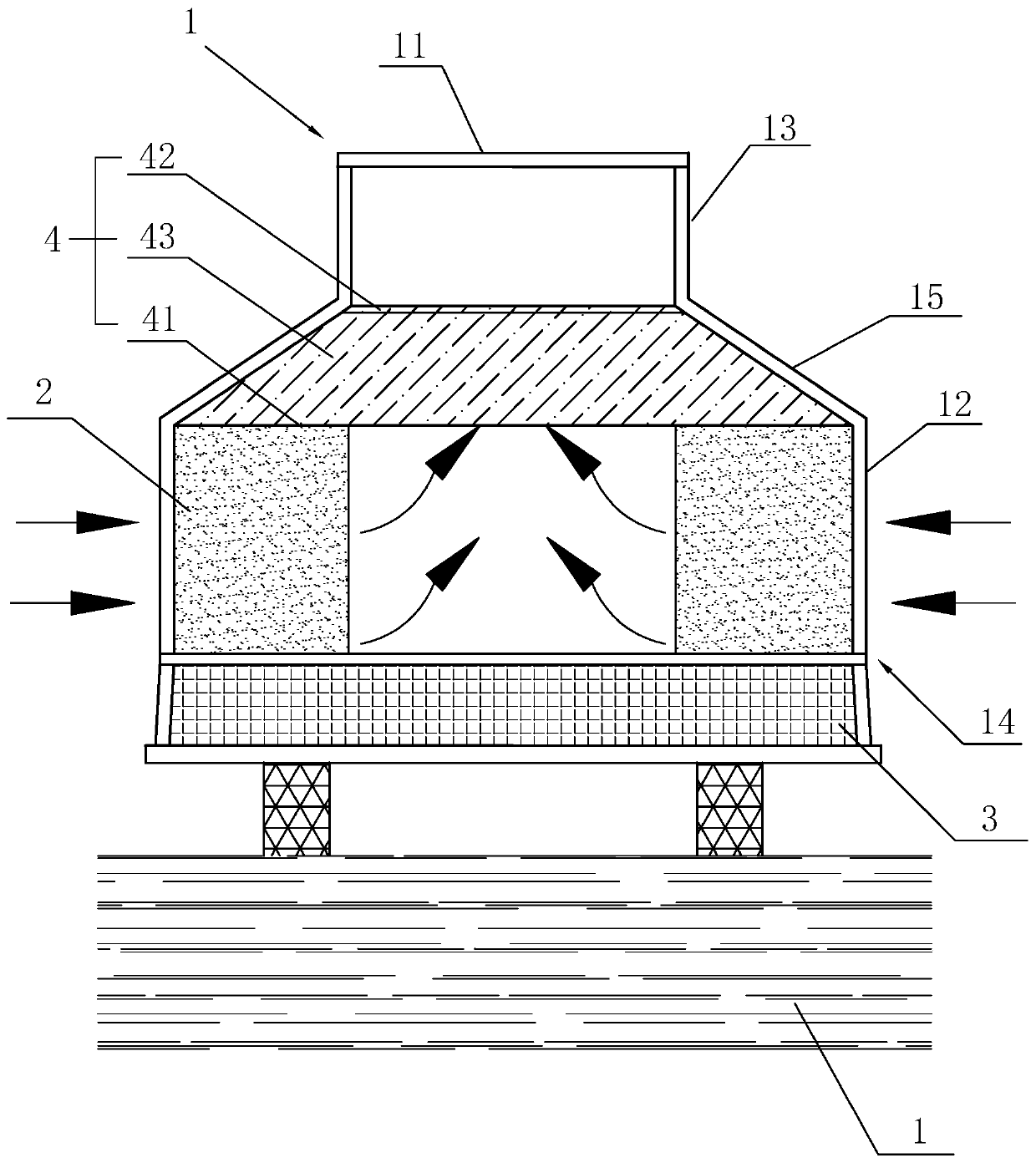

[0040] refer to figure 1, the present invention provides a cooling water tower, comprising a tower body 1, a drying layer 2 and a sump 3, the tower body 1 is placed on the ground, an upper end 13 of the tower body 1 is provided with a water inlet 11, and the sump 3 is arranged on Below the tower body 1 , the side of the tower body 1 is provided with an air inlet channel 12 .

[0041] When using the cooling water tower 77 to cool the high-temperature cooling water, the cooling water will enter the inside of the tower body 1 from the water inlet 11 above the tower body 1, and the outside air will enter the inside of the tower body 1 from the air inlet channel 12 and enter the tower body. The air in 1 will first pass through the drying layer 2. The drying layer 2 can absorb the moisture in the air, increase the drying coefficient of the air, and reduce the humidity coefficient of the air. Molecules will continue to evaporate in the air to become water vapor molecules, and the av...

Embodiment 2

[0050] refer to Figure 4 , the present invention provides a cooling system for the industrial production line of basalt fiber, capable of cooling the kiln 6 in the industrial production line of basalt fiber, which includes the cooling water tower 77, water inlet pipe 71, water outlet pipe 72 and cold water pump 73 in Embodiment 1 One end of the water inlet pipe 71 communicates with the inside of the cooling water tower 77 from the position of the water inlet 11 of the cooling water tower 77, and the other end extends to the top of the kiln 6, and one end of the water outlet pipe 72 communicates with the inside of the sump 3 at the bottom of the sump 3, The other end extends towards the direction close to the kiln 6, and extends upwards on the outer surface of the kiln 6 in a spiral shape after extending to the bottom of the kiln 6, and finally communicates with the end of the water inlet pipe 71 close to the kiln 6, and the cold water pump 73 is arranged on On the outlet pipe...

Embodiment 3

[0060] refer to Figure 5 The difference between this embodiment and the second embodiment is that: the water inlet pipe 71 is provided with a hot water pump 76 and a backup water pump 74 with the same structure as the cold water pump 73, and the backup water pump 74 and the hot water pump 76 on the water inlet pipe 71 are arranged in parallel, and the heat Both the water pump 76 and the standby water pump 74 are located on the side of the regulating valve 75 away from the cooling water tower 77 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com