Method for synthesizing carbon quantum dots by using hydrolyzed polymaleic anhydride as main raw material

A technology of polymaleic anhydride and carbon quantum dots, which is applied in the field of fluorescent materials to achieve the effects of stable chemical properties, simple preparation process, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for synthesizing carbon quantum dots by hydrolyzing polymaleic anhydride, including the following processes:

[0039] Weigh 2.5000g HPMA (Tech, 50%) and dissolve in 46.2500g deionized water, stir well;

[0040] Add 1.2626g of ethylenediamine (Tech, 99%) solution (mass ratio HPMA / EN=1:1) to the above system, mix well, and place in a closed hydrothermal reaction synthesis kettle;

[0041] The reaction kettle was placed in an oven and heated to 180°C, reacted for 5 hours, and naturally cooled to room temperature to obtain a brownish-yellow liquid;

[0042] The above-mentioned brownish-yellow liquid passed through After filtering through the microporous membrane, the fluorescent carbon quantum dot solution is obtained.

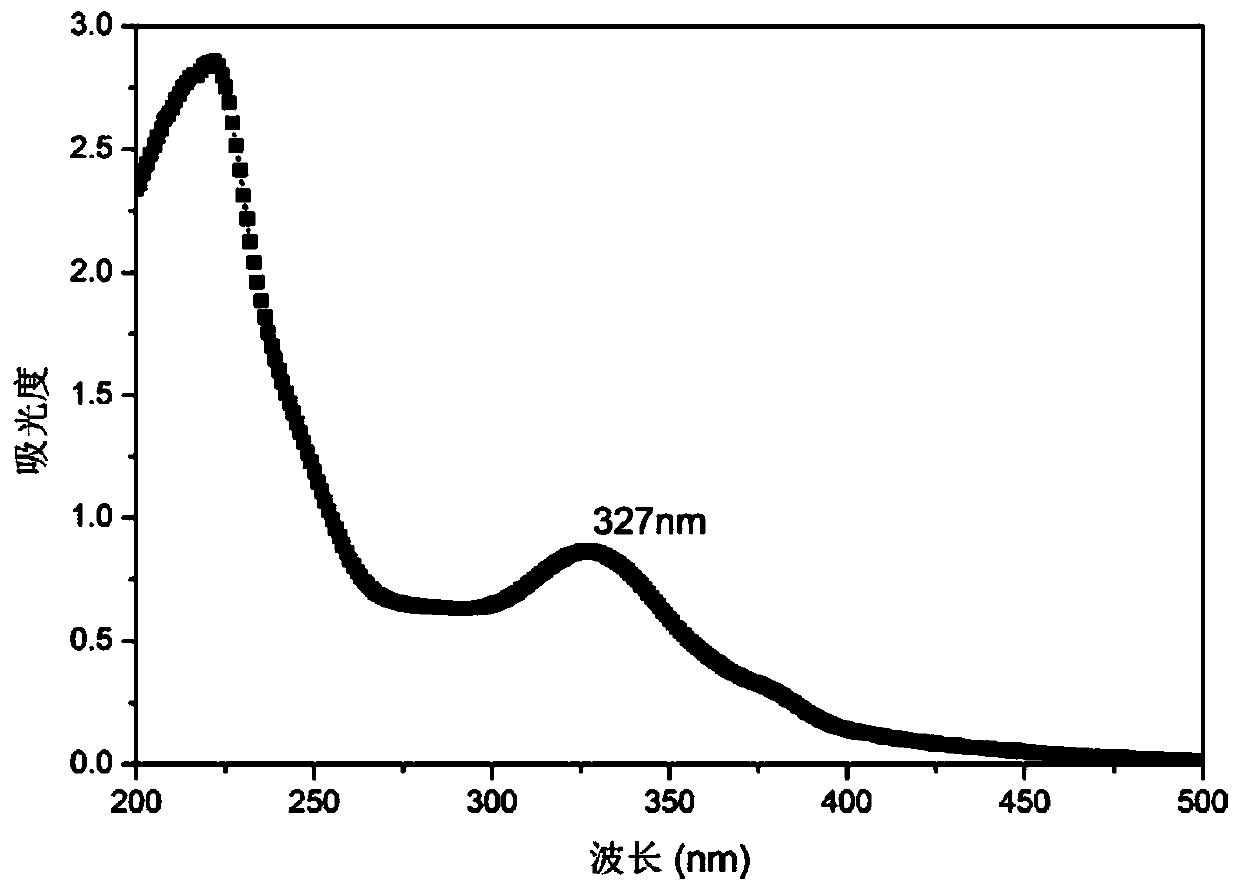

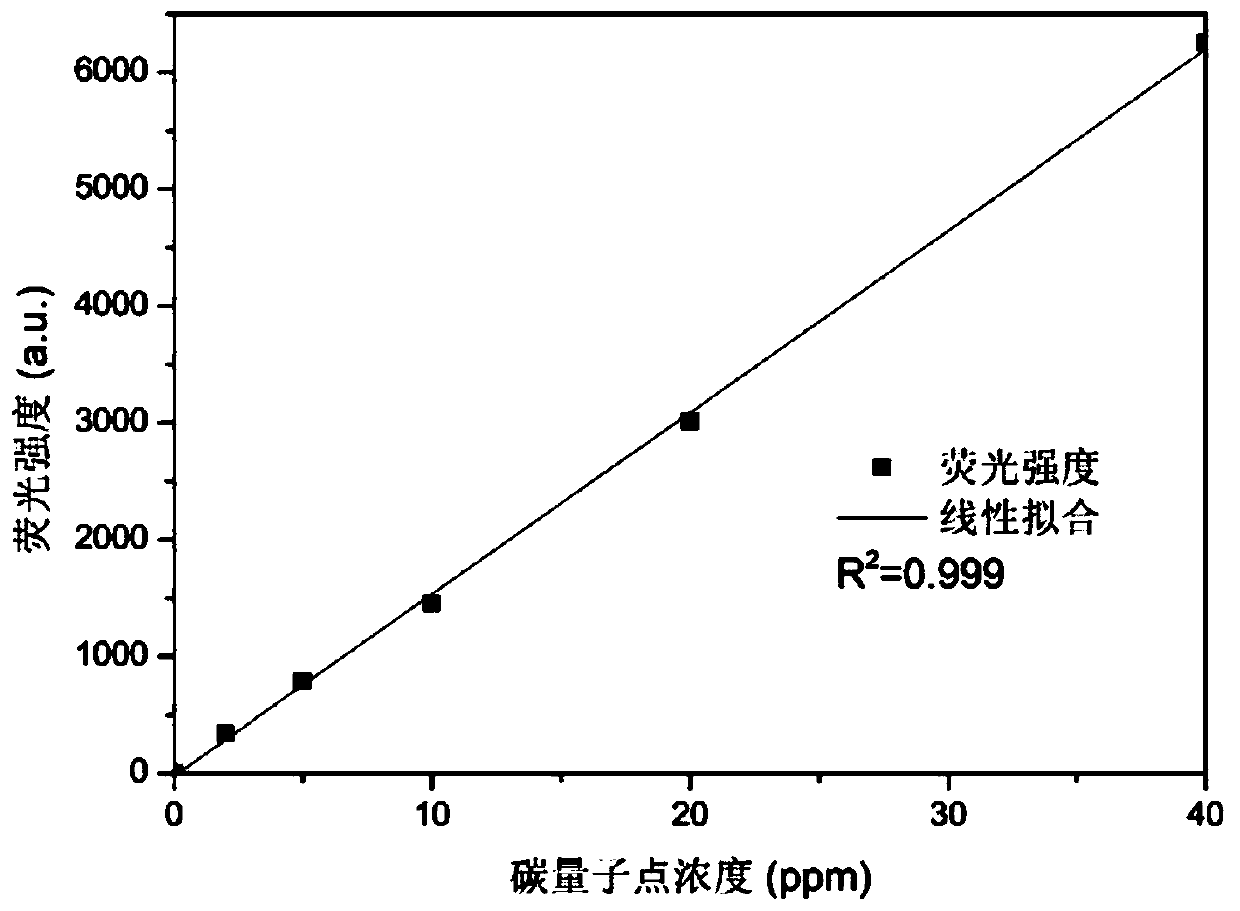

[0043] Get this fluorescent carbon quantum dot solution dilution, by absorption spectrum scanning, the characteristic absorption peak that obtains this quantum dot is 327nm ( figure 1 ); further dilute the fluorescent c...

Embodiment 2

[0046] This embodiment provides a method for synthesizing carbon quantum dots by hydrolyzing polymaleic anhydride, including the following processes:

[0047] Weigh 3.3333g HPMA (Tech, 50%) and dissolve in 45.8334g deionized water, stir well;

[0048]Add 0.8333g of ethylenediamine (Tech, 99%) solution (mass ratio HPMA / EN=2:1) to the above system, mix well, and place in a closed hydrothermal reaction synthesis kettle;

[0049] The reaction kettle was placed in an oven and heated to 180°C, reacted for 5 hours, and naturally cooled to room temperature to obtain a brownish-yellow liquid;

[0050] The above-mentioned brownish-yellow liquid passed through After filtering through the microporous membrane, the fluorescent carbon quantum dot solution is obtained.

Embodiment 3

[0052] This embodiment provides a method for synthesizing carbon quantum dots by hydrolyzing polymaleic anhydride, including the following processes:

[0053] Weigh 1.6667g HPMA (Tech, 50%) and dissolve in 46.6666g deionized water, stir well;

[0054] Add 1.6667g of ethylenediamine (Tech, 99%) solution (mass ratio HPMA / EN=0.5:1) to the above system, mix well, and place in a closed hydrothermal reaction synthesis kettle;

[0055] The reaction kettle was placed in an oven and heated to 180°C, reacted for 5 hours, and naturally cooled to room temperature to obtain a brownish-yellow liquid;

[0056] The above-mentioned brownish-yellow liquid passed through After filtering through the microporous membrane, the fluorescent carbon quantum dot solution is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com