High-performance heat-conducting silicone grease and preparation method thereof

A heat-conducting silicone grease and high-performance technology, which is applied in the field of high-performance thermal-conducting silicone grease and its preparation, can solve problems such as difficulty in dispersion, affecting thermal conductivity, and complexity, and achieve the effects of reducing interface thermal resistance, simplifying the preparation process, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、3、6

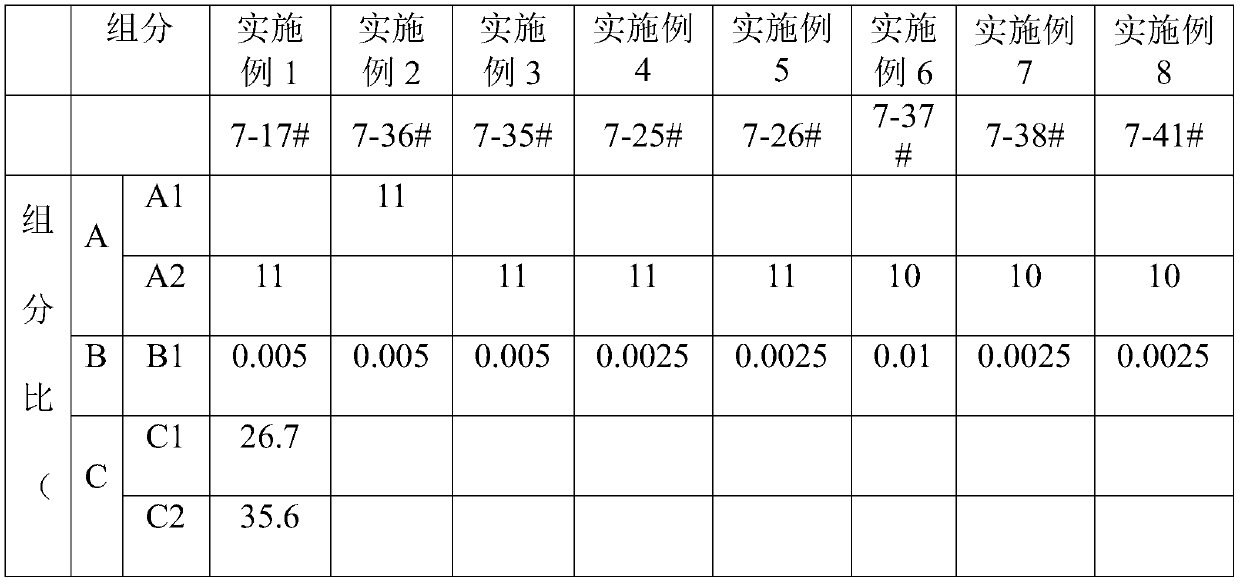

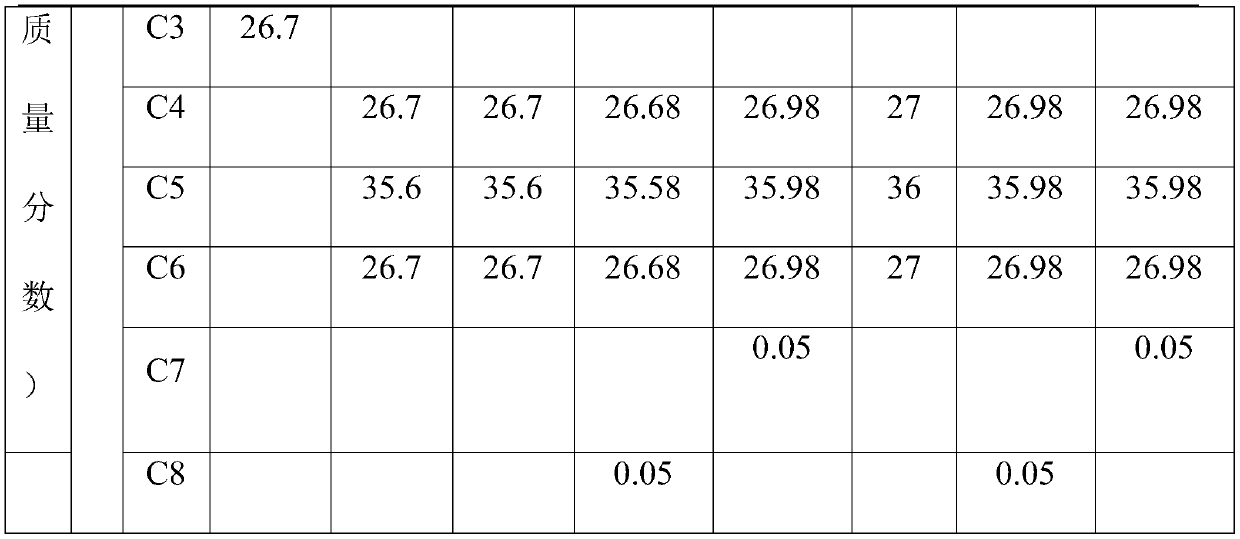

[0019] The preparation steps of embodiment 1, 2, 3, 6 thermal conductive silicone grease are as follows:

[0020] (1) Mix the modifier and the base heat transfer oil in proportion, heat and stir at 90°C for 0.5h to obtain mixture 1;

[0021] (2) Add the alumina powder to the mixture 1 after grading according to the ratio in Table 1, and then stir for 0.5h to obtain the premix;

[0022] (3) Grind the premix in a three-roll machine for 1-2 hours, and then vacuumize to obtain a homogeneous heat-conducting silicone grease.

[0023] The preparation steps of embodiment 4,5,7,8 thermal conductive silicone grease are as follows:

[0024] (1) The modifying agent with 5% powder mass is prepared into a solution with a concentration of 0.1% with ethanol solution, and then thermally conductive fillers C7 and C8 graphene are added to the solution, heated and stirred at 50° C. for 1 hour to obtain a mixed solution, and then put Go into oven and dry, obtain the graphene after modification; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com