Self-healing flexible composite material and preparation method thereof

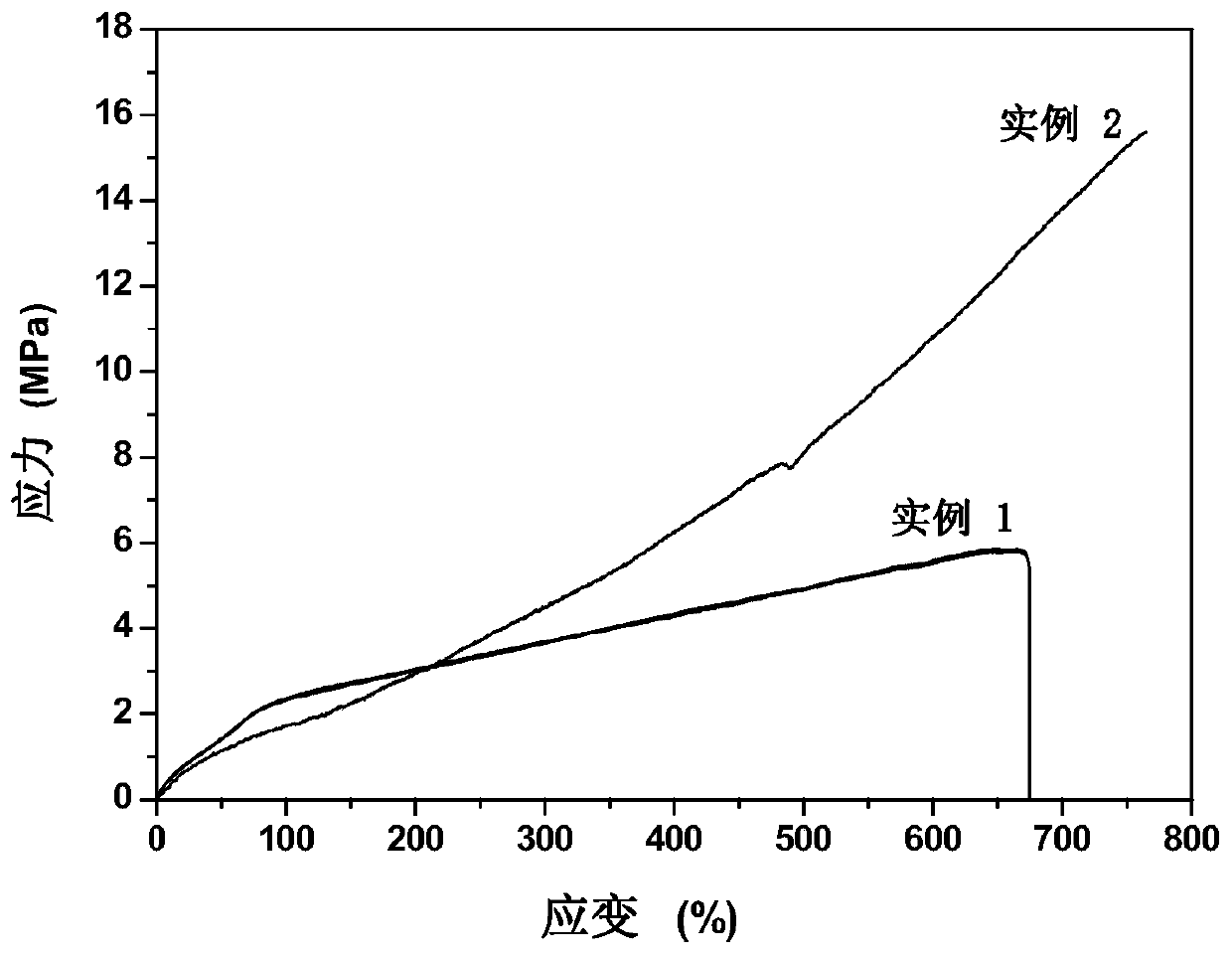

A composite material, self-healing technology, applied in the direction of organic chemistry, organic chemistry, etc., can solve the problems of poor dispersion and low self-healing efficiency of polymer composite materials, achieve enhanced mechanical strength, excellent self-healing performance, increase The effect of interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

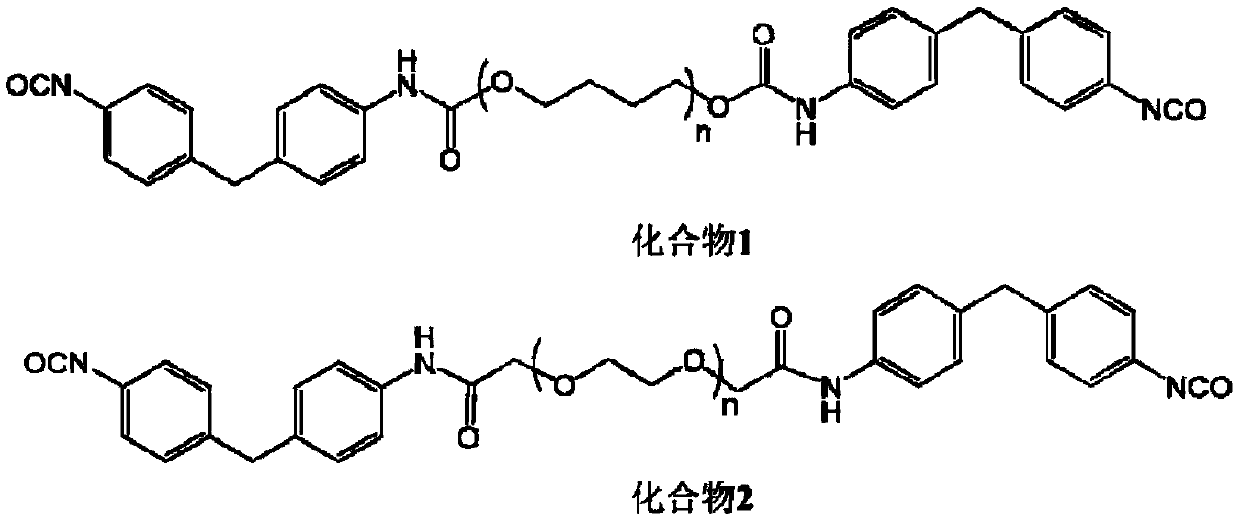

[0037] (1) Dissolve 0.02mol of compound 1 in N,N'-dimethylformamide, add 0.04mol of furan-3-methanol under nitrogen atmosphere, and react at 80°C for 5h;

[0038] (2) Preparation of maleimide derivatives

[0039] Dissolve 0.01mol of 1,8-octanediamine and 0.02mol of maleic anhydride in chloroform, react in ice bath for 4 hours, react at room temperature for 24 hours, collect the precipitate by filtration, add triethylamine, acetic anhydride and nickel acetate after drying, Dissolved in acetone, heated to reflux for 6 hours to collect the product, and further recrystallized with a mixed solution of chloroform:methanol=5:3 (v / v) to obtain the maleimide derivative 1;

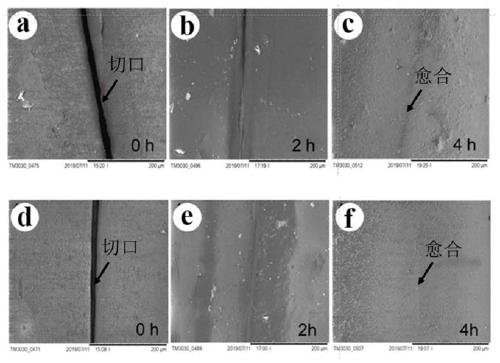

[0040] (3) Add 0.02 mol of maleimide derivative 1 to the reaction solution in step (1), and continue to react at 80°C for 3 hours; after the reaction, pour the reaction solution into a mold, and dry the volatile solvent to obtain a flexible material ; Use a blade to draw a wound on the obtained material, and the se...

Embodiment 2

[0048] (1) Disperse 0.15wt% graphene oxide in N,N'-dimethylformamide, add 4,4'-methylene bis(phenylisocyanate), and then react at 100°C for 2h, the reaction After completion, obtain isocyanate group-terminated graphene oxide; add 3-furfuraldehyde to the reaction solution that has completed the reaction, and react at 120° C. for 4 hours under an atmosphere of inert gas, and obtain furan-functionalized graphene oxide after the reaction is completed;

[0049] (2) The functionalized graphene oxide containing furan group obtained in step 1) and the maleimide derivative obtained in step 2) of Example 1 are mixed for Diels-Alder reaction, and self-healing properties are obtained after the reaction is completed flexible composite material; Diels-Alder reaction conditions: temperature 120 ℃, time 3h.

Embodiment 3

[0051] (1) Dissolve maleic anhydride and 1,5-naphthalene diamine in chloroform, react in ice bath for 4 hours, react at room temperature for 24 hours, collect the precipitate by filtration, add triethylamine, acetic anhydride, nickel acetate after drying, dissolve In acetone, heat and reflux for 6 hours to collect the product, and further precipitate with a large amount of ether to obtain the maleimide derivative 2;

[0052] (2) Mix the furan-functionalized graphene oxide obtained in step 1) of Example 2 and the maleimide derivative obtained in step 1) to perform Diels-Alder reaction, and obtain a flexible composite material with self-healing properties after the reaction is completed ; Diels-Alder reaction conditions: temperature 40 ℃, time 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com