Process method for separating talc and chalcopyrite through three-step method and collecting agent used in process method

A process method and a three-step technology, applied in the field of collectors, can solve the problems that talc and copper sulfide minerals cannot be effectively separated, and achieve the effects of avoiding a large degree of foam richness, strengthening the collection capacity, and reducing surface tension

Active Publication Date: 2020-08-25

安徽铜冠产业技术研究院有限责任公司

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The object of the present invention is to provide a three-step process for separating talc and chalcopyrite, to solve the technical problem of beneficiation that talc and copper sulfide minerals cannot be effectively separated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

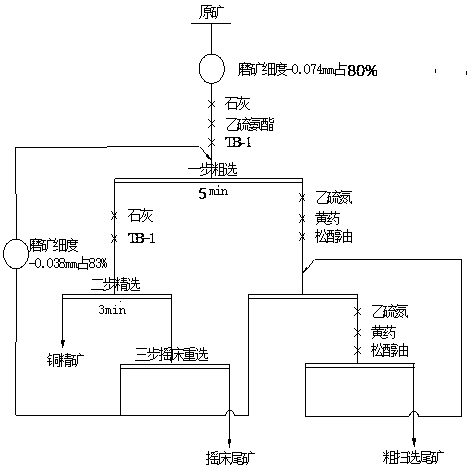

Embodiment 2

[0058] Table 5 Embodiment 2 Flotation test index (wt%)

[0059] product name Yield copper grade Copper recovery rate copper concentrate 3.53 20.80 87.42 shaker tailings 7.60 0.345 3.12 Rough sweeping tailings 88.87 0.089 9.46 Raw ore 100.00 0.84 100.00

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

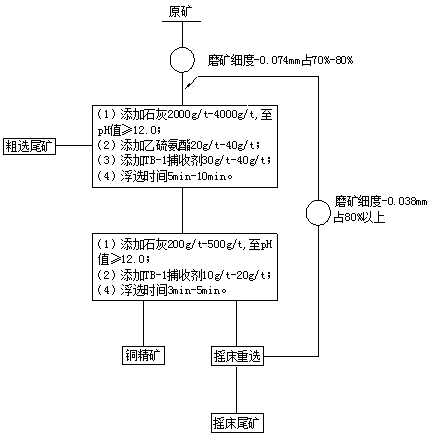

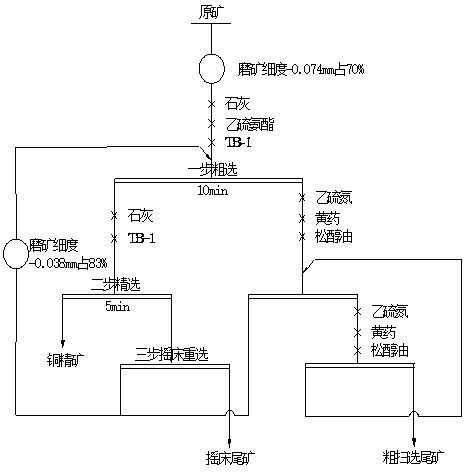

The invention provides a process method for separating talc and chalcopyrite through a three-step method and a collecting agent used in the process method. The method comprises the steps of carrying out ore grinding, carrying out first-step roughing, carrying out second-step concentration, and carrying out third-step table reselection and regrinding operation. The process method aims at separationof the talc and the chalcopyrite, the preferential copper separation technological process is adopted for the first time under the condition that a special-effect talc inhibitor is not added, and effective separation of the talc and the chalcopyrite is achieved. According to the process method, the collecting agent TB-1 formed by mixing isobutyl xanthate propionitrile ester, N-allyl-O-alkyl thiocarbamate and Spans type sorbitan ester is adopted to strengthen flotation of the chalcopyrite, the thickness of a foam layer is adjusted through the defoaming performance of the collecting agent TB-1,and the relative floating speed of the talc and the chalcopyrite is changed; and the flotation and reselection combined technological process is adopted, and effective separation of talc and chalcopyrite is achieved through three steps. The flotation reagent adopted in the process method has the characteristics of low toxicity or no toxicity, environment friendliness, good effect and the like, and an environment-friendly and high-efficiency process method for separating the talc and the chalcopyrite is provided.

Description

technical field [0001] The invention relates to the technical field of mineral processing engineering, in particular to a process for separating talc and chalcopyrite and a used collector. Background technique [0002] The separation of talc and chalcopyrite is a recognized technical problem in the field of mineral processing. Due to the low hardness of talc and its natural buoyancy, there is a large amount of easily floatable slime in the flotation pulp, which is produced together with the concentrate, resulting in Decrease in concentrate grade. At the same time, the proportion of talc-type copper sulfide minerals is increasing, and the smelting industry has increasingly high requirements for concentrate quality, which makes it important to realize the efficient separation and recovery of talc and chalcopyrite. [0003] At present, there are two main methods for the separation of talc and chalcopyrite: one is to use the physical properties and flotation characteristics of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03B7/00B03B9/00B03D1/018B03D101/02B03D103/02

CPCB03B7/00B03B9/00B03D1/018B03D2201/02B03D2203/02

Inventor 丁鹏王周和姚道春张驰董世华周贵斌彭时忠庞勃郭运鑫朱继生李沛原

Owner 安徽铜冠产业技术研究院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com