Drug-loaded embolism microsphere with developing function and preparation method thereof

A technology of embolization and microspheres, applied in the fields of medical developing materials and medical devices, can solve the problems of residual organic solvent, affect the reactivity, complicated operation steps, etc., and achieve the effect of avoiding the use of heavy metal elements, fully reacting, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

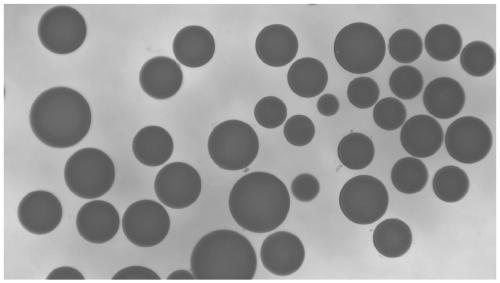

[0061] Example 1: Preparation of Developable Polyvinyl Alcohol Embolization Microspheres

[0062] Step 1: Preparation of reverse phase suspension polymer oil phase

[0063] Using the reverse phase suspension polymerization method, add 100ml of butyl acetate into a four-necked bottle, weigh 1.2g of cellulose acetate butyrate, and dissolve it under the condition of heating and stirring in a constant temperature water bath at 60°C until a uniform oil phase system is formed. The reaction device is an electric stirrer (model JJ-1A) routinely used in the laboratory, and the constant temperature water bath is Changzhou Jintan digital display constant temperature water bath.

[0064] Step 2: Prepare the water phase of the reversed-phase suspension polymerization system

[0065] Prepare an aqueous solution of polyvinyl alcohol with a mass fraction of 10% under the condition of heating in a constant temperature water bath at 90°C for subsequent use;

[0066] Weigh 3.73g of iohexol and...

Embodiment 2

[0070] Example 2: Preparation of Developable Polyvinyl Alcohol Embolization Microspheres

[0071] Step 1: Preparation of reverse phase suspension polymer oil phase

[0072] Using the reverse-phase suspension polymerization method, add 100ml of butyl acetate into a four-necked bottle, weigh 1.5g of cellulose acetate butyrate, and dissolve it under the condition of heating and stirring in a constant temperature water bath at 60°C until a uniform oil phase system is formed. The reaction device is an electric stirrer (model JJ-1A) routinely used in the laboratory, and the constant temperature water bath is Changzhou Jintan digital display constant temperature water bath.

[0073] Step 2: Prepare the water phase of the reversed-phase suspension polymerization system

[0074] Prepare a polyvinyl alcohol aqueous solution with a mass fraction of 15% under the heating condition of a 95°C constant temperature water bath (the constant temperature water bath is Changzhou Jintan digital d...

Embodiment 3

[0079] Example 3: Preparation of Developable Gelatin Embolization Microspheres

[0080] Step 1: Preparation of reverse phase suspension polymer oil phase

[0081] Using the reverse phase suspension polymerization method, add 100ml of liquid paraffin into the four-necked bottle, measure 1.5ml of Span 80 into the four-necked bottle, stir the mixture of liquid paraffin and Span 80 until a uniform oil phase system is formed, The stirring reaction device used is an electric stirrer (model JJ-1A) routinely used in the laboratory.

[0082] Step 2: Prepare the water phase of the reversed-phase suspension polymerization system

[0083] Prepare a gelatin aqueous solution with a mass fraction of 15% under the heating condition of a constant temperature water bath at 50°C (the constant temperature water bath is Changzhou Jintan digital display constant temperature water bath);

[0084] Weigh 1.2g of triiodobenzyl alcohol and dissolve it in 7ml of dimethyl sulfoxide to prepare a triiodob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com