Coated multi-element positive electrode material for lithium ion battery, preparation method and application thereof

A positive electrode material and coating technology, which is applied in the field of lithium ion battery electrode materials, can solve the problems of poor high temperature cycle stability and poor material cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

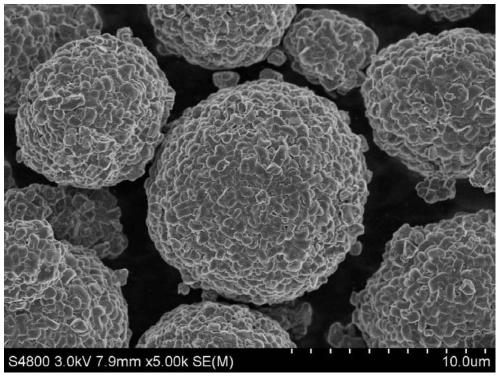

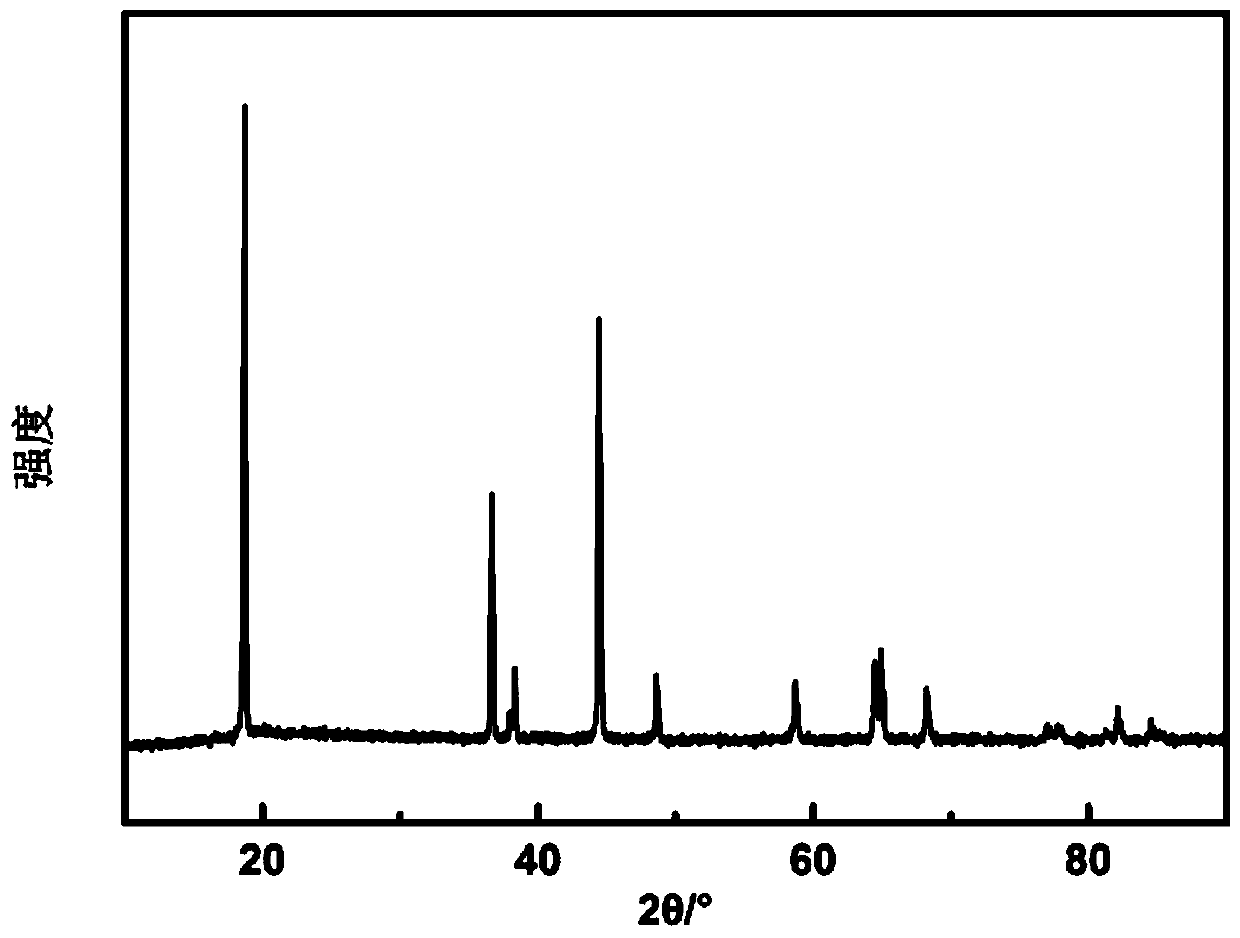

[0086] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.8 co 0.1 mn 0.1 (OH) 2 , after washing, drying or heat treatment, the Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor products.

[0087] (2) The precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Product and lithium source are fully mixed, and wherein, lithium: the mol ratio of transition metal (Ni+Co+Mn) is 1.05. Raise the fully mixed precursor material to 800°C at 1.5°C / min in an oxygen atmosphere and keep it warm for 15 hours to obtain the untreated matrix high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 .

[0088] (3) Mix strontium oxide and indium oxide uniformly in a certain proportion (the molar ratio of indium to strontium is 9:1), sinter at 900°C for 20 hours, cool to room temperature, and use a high-energy ball mill to grind it into 200nm-500nm The powder is coated.

[0089] (4) The obtained untreated substrate high-nickel cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Add it into dei...

Embodiment 2

[0099] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.815 co 0.15 al 0.035 (OH) 2 , after washing, drying or heat treatment, the Ni 0.815co 0.15 al 0.035 (OH) 2 Precursor products.

[0100] (2) The precursor Ni 0.815 co 0.15 al 0.035 (OH) 2 Product and lithium source are fully mixed, and wherein, lithium: the mol ratio of transition metal (Ni+Co+Mn) is 1.05. Raise the fully mixed precursor material to 800°C at 1.5°C / min in an oxygen atmosphere and keep it warm for 15 hours to obtain the untreated matrix high-nickel cathode material LiNi 0.815 co 0.15 al 0.035 o 2 .

[0101] (3) Mix strontium oxide and indium oxide uniformly in a certain proportion (the molar ratio of indium to strontium is 9:1), sinter at 900°C for 20 hours, cool to room temperature, and use a high-energy ball mill to grind it into 200nm-500nm The powder is coated.

[0102] (4) The obtained untreated substrate high-nickel cathode material LiNi 0.815 co 0.15 al 0....

Embodiment 3

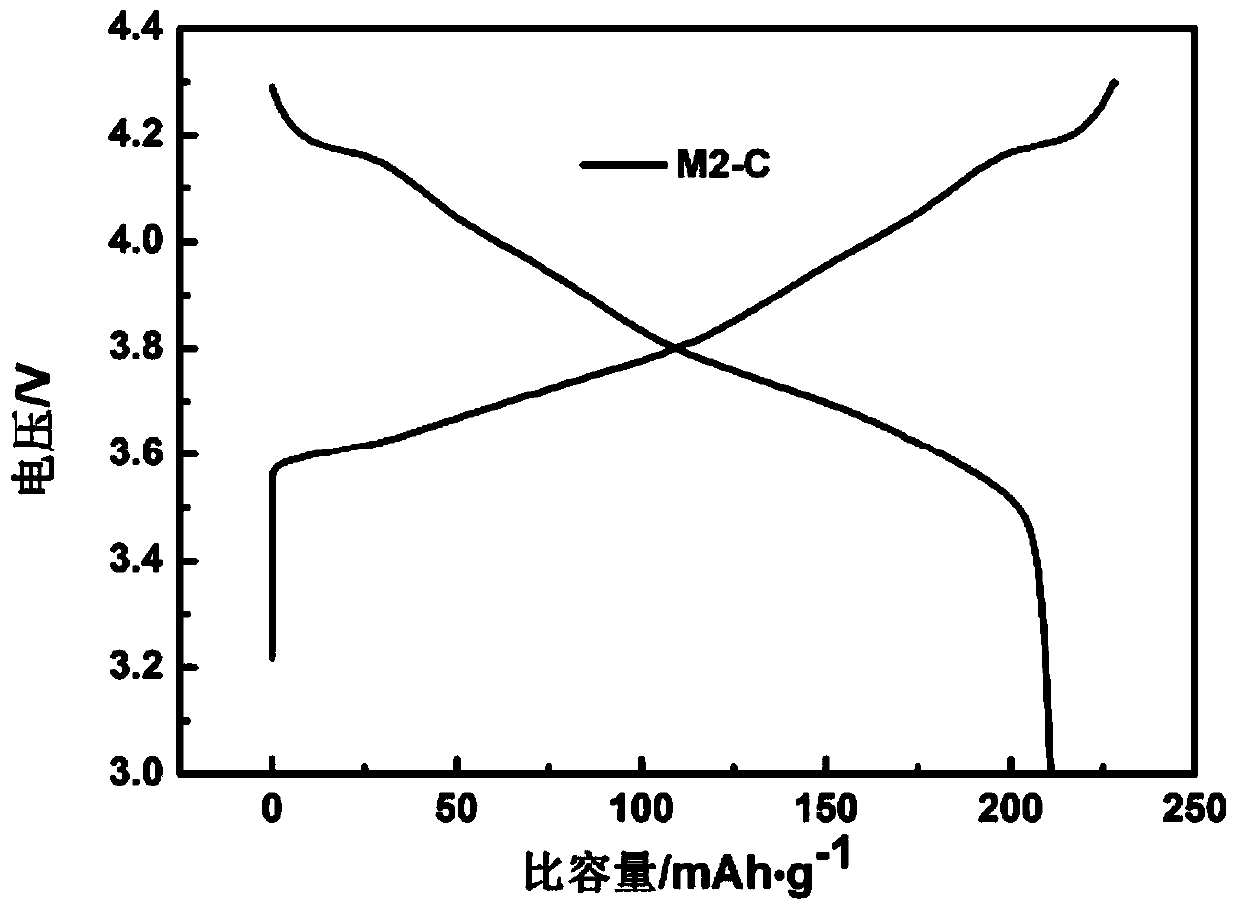

[0106] (1) Synthesis of high-nickel precursor Ni by co-precipitation technology 0.6 co 0.2 mn 0.2 (OH) 2 , after washing, drying or heat treatment, the Ni 0.6 co 0.2 mn 0.2 (OH) 2 Precursor products.

[0107] (2) Mix strontium oxide and indium oxide in a certain proportion (the molar ratio of indium to strontium is 9:1), sinter at 900°C for 20 hours, cool to room temperature, and use a high-energy ball mill to grind it into 200nm-500nm The powder is coated.

[0108] (3) The precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 The product, lithium source and the above-mentioned coating are fully mixed, and the coating amount (precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 The mass is 100%, the usage amount of coating) is 0.5%, wherein, the molar ratio of lithium:transition metal (Ni+Co+Mn) is 1.05. The fully mixed precursor material was raised to 850°C at 1.5°C / min in an oxygen atmosphere, and kept for 15 hours to obtain the coated and modified ternary cathode material, that is, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com