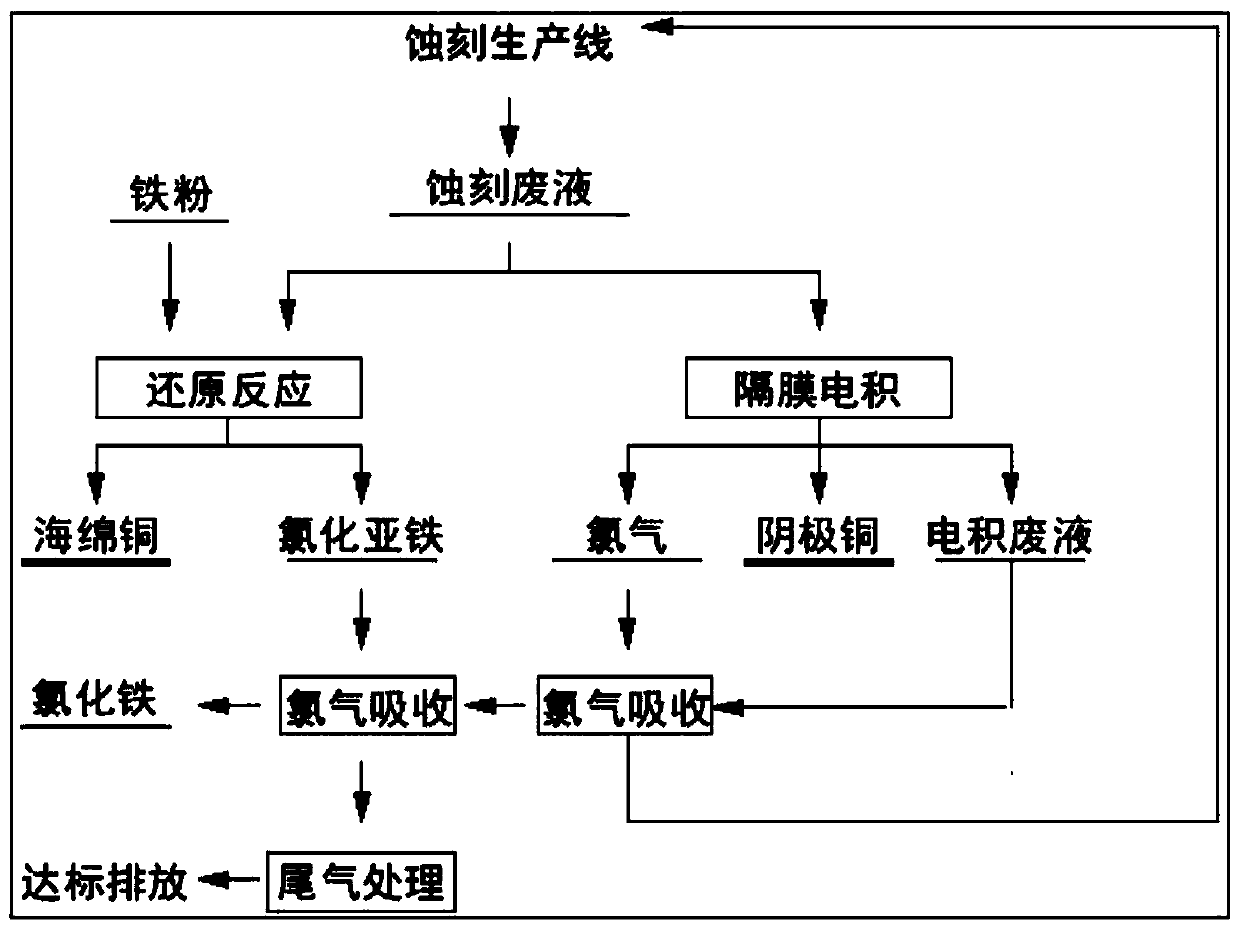

Method for online recovery of copper and chlorine from acidic waste etching liquid and regeneration of etching liquid

A technology of acidic etching waste liquid and etching waste liquid, which is applied in the field of regeneration of chlorine gas and etching liquid, and online recovery of copper from acidic etching waste liquid, so as to achieve the effect of improving recovery rate and avoiding increment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The acidic etching waste liquid is taken from the etching production line of a circuit board factory in Hubei. The factory produces 200-300 tons of acidic etching waste liquid every month, containing 126.29 grams / liter of copper and 91.35 grams / liter of hydrochloric acid. 70% of the electrowinning liquid is transported to the diaphragm electrolyzer, and at 40°C, direct current is applied to produce copper plates, chlorine gas, and electrowinning waste liquid. After the electrowinning waste liquid absorbs chlorine gas in the dissolving and absorbing tank, hydrochloric acid is added to make the hydrochloric acid content of the solution 2.6mol / L, add sodium chlorate to make the ORP value of the solution 500mv, and then return the new etching solution to the etching process, and the cathode copper plate in the electrolytic cell can be stripped and recovered after 6 days of electrolysis; meanwhile, 30% of the total amount of acidic etching waste liquid % into the reaction ke...

Embodiment 2

[0044] The acidic etching waste liquid is taken from the etching production line of a circuit board factory in Guangdong. The factory produces 300-350 tons of acidic etching waste liquid every month, containing 115.39 g / L of copper and 105.40 g / L of hydrochloric acid. 60% of the electrowinning liquid is transported to the diaphragm electrolyzer, and at 45°C, direct current is applied to generate copper plates, chlorine gas, and electrowinning waste liquid. After the electrowinning waste liquid absorbs chlorine gas in the dissolving and absorbing tank, hydrochloric acid is added to make the hydrochloric acid content of the solution 2.9mol / L, add sodium chlorate to make the ORP value of the solution 460mv, and then return the new etching solution to the etching process, and the cathode copper plate in the electrolytic cell can be stripped and recovered after 7 days of electrolysis; at the same time, 40% of the total amount of acidic etching waste solution % into the reaction ket...

Embodiment 3

[0047] The acidic etching waste liquid is taken from the etching production line of a circuit board factory in Jiangsu. The factory produces 200-250 tons of acidic etching waste liquid every month, containing 109.39 grams / liter of copper and 121.75 grams / liter of hydrochloric acid. 75% of the electrowinning liquid is transported to the diaphragm electrolyzer, and at 48°C, direct current is applied to generate copper plates, chlorine gas, and electrowinning waste liquid. After the electrowinning waste liquid absorbs chlorine gas in the dissolving and absorbing tank, hydrochloric acid is added to make the hydrochloric acid content of the solution 3.2mol / L, add sodium chlorate to make the ORP value of the solution 480mv, and then return the new etching solution to the etching process, and the cathode copper plate in the electrolytic cell can be stripped and recovered after 6 days of electrolysis; at the same time, 25% of the total amount of acidic etching waste liquid % into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com