Method for preparing three-dimensional hierarchical pore carbon of lithium-sulfur battery cathode material by template method

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve problems such as low conductivity, achieve low prices, accelerate redox reaction kinetics, and relieve volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment 1: A template method of this embodiment to prepare three-dimensional hierarchical porous carbon for lithium-sulfur battery cathode material is carried out according to the following steps:

[0029] 1. Preparation of Precursor Film

[0030] Put 2g of cellulose acetate, 0.5g of polymethyl methacrylate and 0.67g of zinc oxide into a clean beaker, add 20ml of N,N-dimethylacetamide as a solvent, heat and stir in a water bath at 50°C for 12h, then Cast the mixed solution on a glass plate and vacuum dry to obtain a white film;

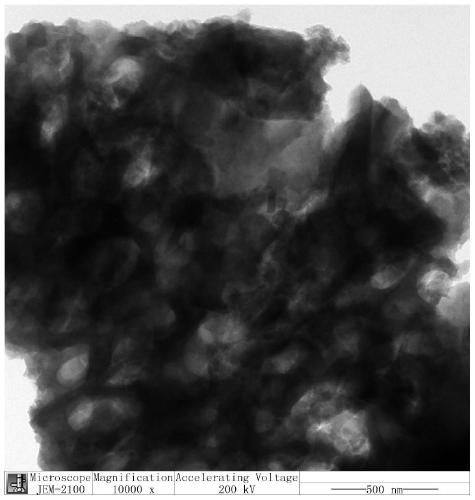

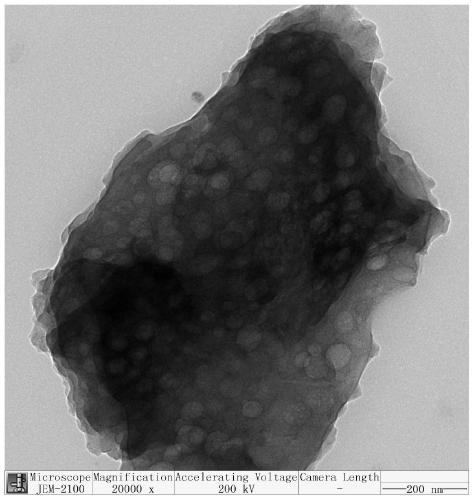

[0031] 2. Preparation of active material carrier conductive carbon materials

[0032] Place the white film obtained in step 1 under a nitrogen atmosphere, raise the temperature to 475°C for 1 hour at a heating rate of 5°C·min Ultrasonic cleaning with % HCl, washing with a large amount of deionized water and drying to obtain a three-dimensional hierarchical porous conductive carbon material;

[0033] 3. Preparation of conductive c...

specific Embodiment approach 2

[0042] Specific embodiment two: The difference between the specific embodiment and the specific embodiment one is that the mass ratio of cellulose acetate and zinc oxide described in step one is 1:1, and the mass ratio of carbon and sulfur in step three is 3:7. Others It is the same as the first embodiment.

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent N,N-dimethylacetamide in step 1 is 22ml. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com