Smelting furnace and smelting method for recovering electrolyte from aluminum electrolysis carbon residues

An electrolyte and smelting furnace technology, applied in the field of aluminum electrolysis, can solve the problems of low production efficiency, long roasting time, harsh working environment, etc., and achieve the effects of improving processing efficiency, increasing reaction area, and convenient process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

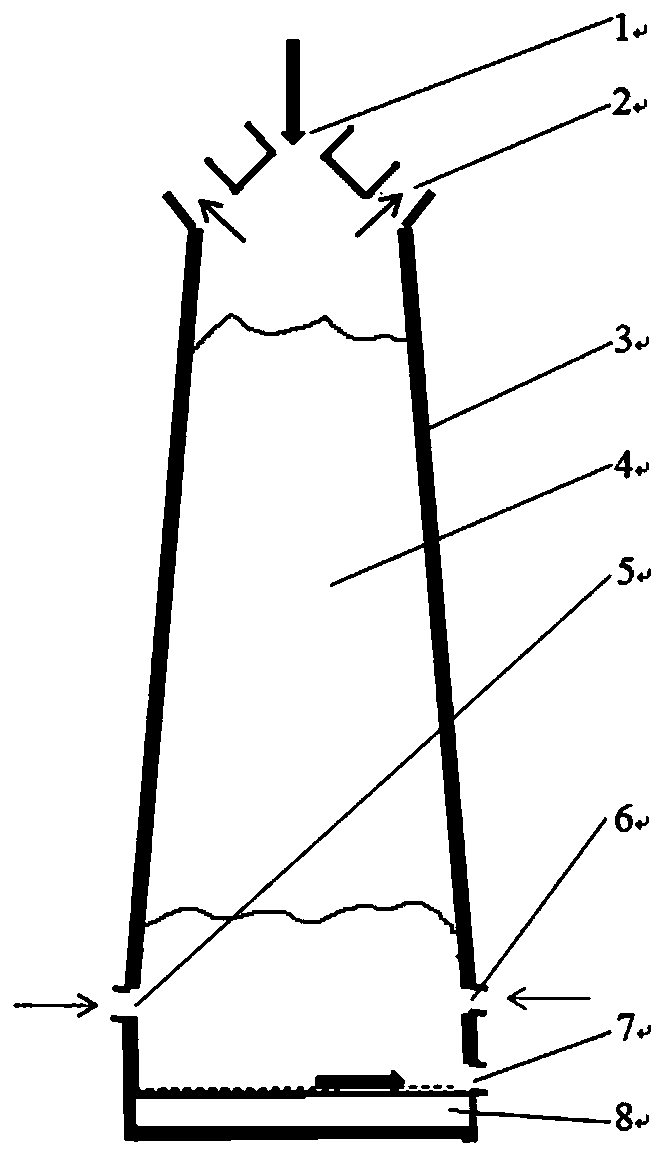

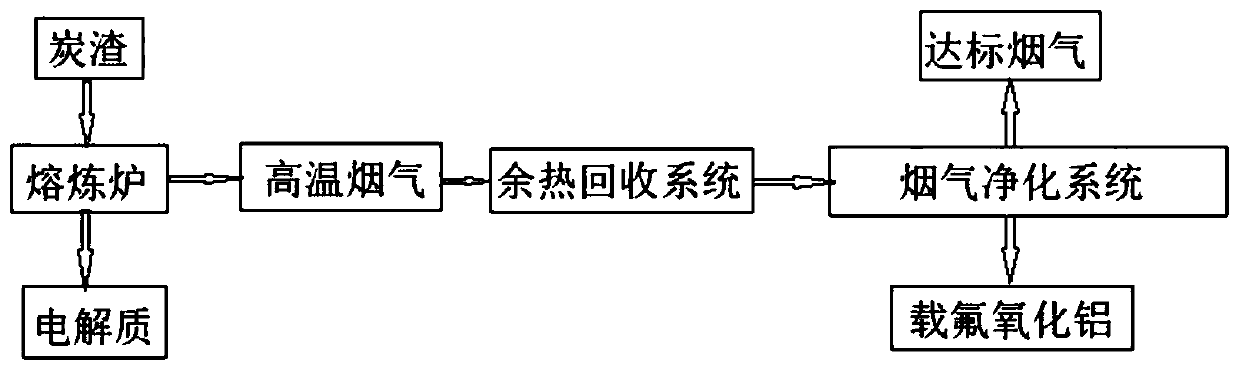

[0023] A smelting furnace for recovering electrolyte from aluminum electrolytic carbon slag according to the present invention is adopted. The smelting furnace is a vertical smelting furnace, which includes a feed inlet 1 at the top, a flue gas outlet 2, a furnace body 3 at the middle, and a Combustion aid inlet 5 near the bottom, fuel inlet 6, electrolyte overflow outlet 7 and electrolyte collection pool 8 at the bottom, the furnace body 3 includes: cryolite layer, corrosion-resistant layer, refractory material layer, heat preservation Material layers and steel plates. The corrosion-resistant layer is made of carbon material with a thickness of 10mm; the refractory material layer has a heat resistance of 1250°C and a thickness of 300mm; the thermal conductivity of the thermal insulation material used in the insulating material layer is 0.45W / (m K) at 25°C, and the thickness is 300mm; the thickness of the steel plate is 3mm.

[0024] Use the carbon contained in the carbon slag...

Embodiment 2

[0031] A smelting furnace for recovering electrolyte from aluminum electrolytic carbon slag according to the present invention is adopted. The smelting furnace is a vertical smelting furnace, which includes a feed inlet 1 at the top, a flue gas outlet 2, a furnace body 3 at the middle, and a Combustion aid inlet 5 near the bottom, fuel inlet 6, electrolyte overflow outlet 7 and electrolyte collection pool 8 at the bottom, the furnace body 3 includes: cryolite layer, corrosion-resistant layer, refractory material layer, heat preservation Material layers and steel plates. The corrosion-resistant layer is made of silicon nitride material with a thickness of 50mm; the refractory material layer has a heat resistance of 1300°C and a thickness of 240mm; the heat-insulating material used for the heat-insulating material layer has a thermal conductivity of 0.35W / (m K) at 25°C and a thickness of 230mm; the thickness of the steel plate 7mm.

[0032] Utilize the carbon contained in the c...

Embodiment 3

[0039]A smelting furnace for recovering electrolyte from aluminum electrolytic carbon slag according to the present invention is adopted. The smelting furnace is a vertical smelting furnace, which includes a feed inlet 1 at the top, a flue gas outlet 2, a furnace body 3 at the middle, and a Combustion aid inlet 5 near the bottom, fuel inlet 6, electrolyte overflow outlet 7 and electrolyte collection pool 8 at the bottom, the furnace body 3 includes: cryolite layer, corrosion-resistant layer, refractory material layer, heat preservation Material layers and steel plates. The corrosion-resistant layer is made of silicon nitride combined with silicon carbide material, with a thickness of 80mm; the refractory material layer has a heat resistance of 1400°C and a thickness of 180mm; the heat-insulating material used for the heat-insulating material layer has a thermal conductivity of 0.3W / (m K) at 25°C and a thickness of 160mm ; Steel plate thickness 12mm.

[0040] Use the carbon co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com