Polyarylene sulfide sulfone containing phthalazinone structure and preparation method thereof

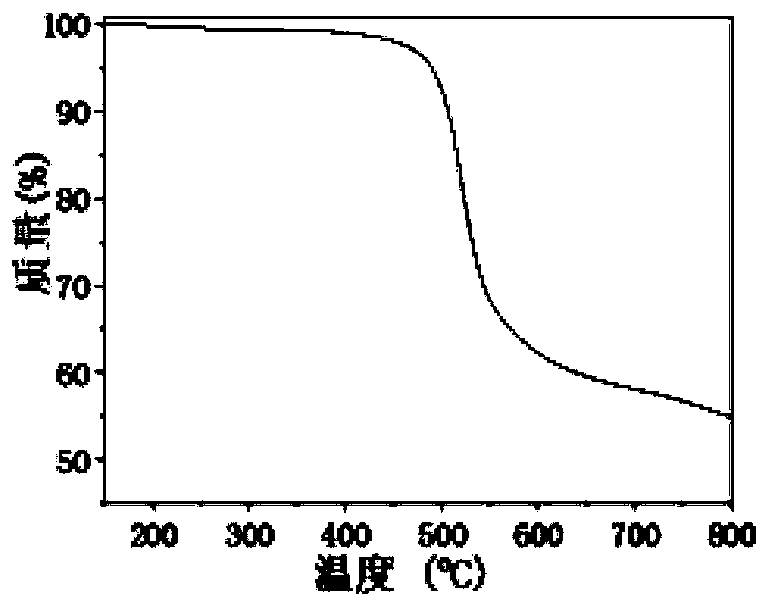

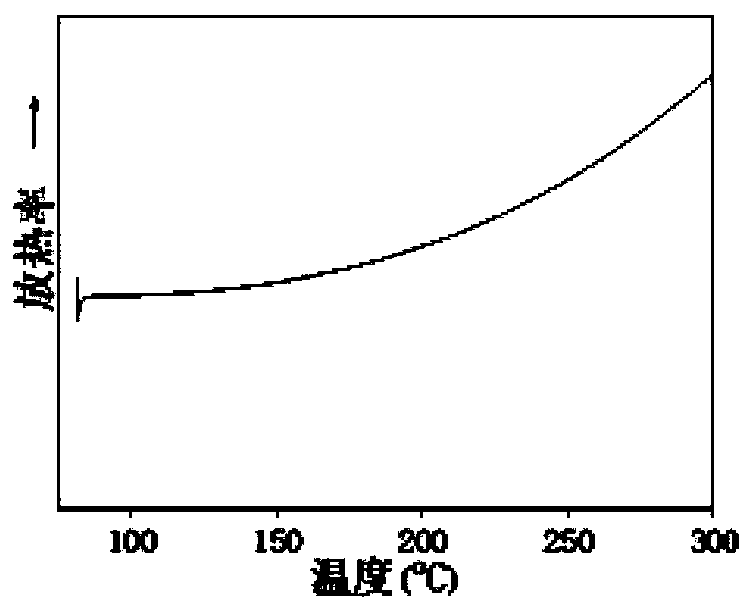

A technology of polyarylene sulfide sulfone and phthalazinone, which is applied in the field of preparation of polyarylene sulfide sulfone, can solve problems such as single structure and few types of polymers, and achieve improved heat resistance, high thermal decomposition temperature, good The effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of polyarylene sulfide sulfone containing a phthalazinone structure, comprising: mixing dihalogen diphenyl sulfone with equimolar bisphenol-like monomers containing a phthalazinone structure and a reaction medium, and reacting The mixing ratio of medium and reaction raw materials (dihalogen diphenyl sulfone and equimolar bisphenol-like monomers containing phthalazinone structure) is 3mL / g~6mL / g, and the reaction medium is dimethyl sulfoxide, Diphenylsulfone, sulfolane, N-methylpyrrolidone, N,N-dimethylformamide or N,N-dimethylacetamide aprotic polar solvent or polar solvent, with sodium hydroxide or potassium hydroxide Or sodium bicarbonate or potassium carbonate is used as a catalyst, and the reaction medium mixed with the reaction raw materials is added together with the catalyst and the azeotropic dehydrating agent in a three-necked flask, and the molar ratio of the catalyst to one of the two reaction raw materials is 1:1~1.2: 1. The volume ratio...

Embodiment 1

[0037] Add 3.0mmol difluorodiphenylsulfone, 3.0mmol 4-(4`-mercapto)phenyl-2,3-naphthyridine, 3.3mmol potassium carbonate, 8mL N,N-dimethylacetamide and 8mL toluene Add it into a three-necked flask, connect the three-necked flask to a condensing water separator, feed nitrogen, and install a mechanical stirrer. Under nitrogen atmosphere, raise the temperature to 150°C, after azeotropic dehydration for 4 hours, remove water and toluene, raise the temperature to 160-165°C, polymerize for 48 hours, after the reaction, cool to 120°C, add 2mL N into the three-necked flask, N-dimethylacetamide, dilute the reaction solution, then pour it into 300mL deionized water, wash and desalt, and bake at 100-120°C for 12 hours to obtain 1.306g of polyarylene sulfide sulfone containing phthalazinone structure, The yield was 93%.

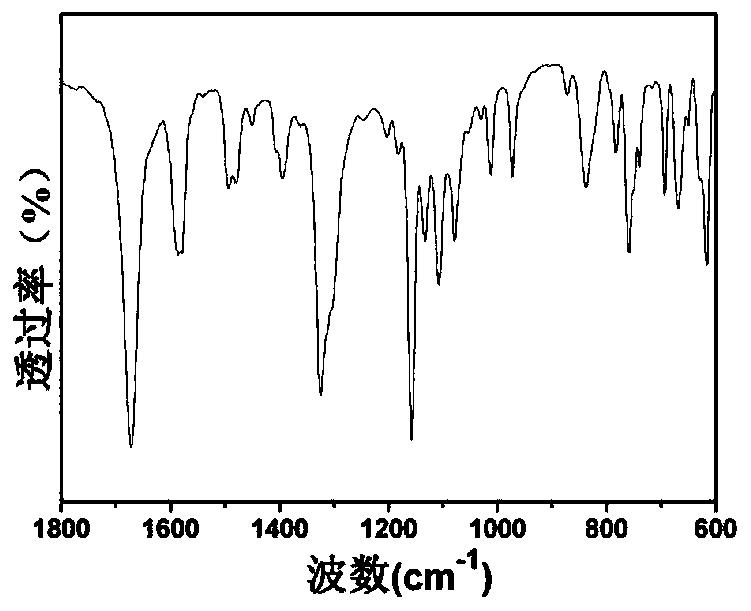

[0038] figure 1 The infrared spectrogram shows that the polyarylene sulfide sulfone obtained by the method of this embodiment has a polymer characteristic functional g...

Embodiment 2

[0040] 3.0mmol dichlorodiphenylsulfone, 3.0mmol 4-(4`-mercapto)phenyl-2,3-naphthyridine, 3.3mmol potassium carbonate, 8mL N,N-dimethylacetamide and 8mL toluene Add it into a three-necked flask, connect the three-necked flask to a condensing water separator, feed nitrogen, and install a mechanical stirrer. Under nitrogen atmosphere, raise the temperature to 150°C, after azeotropic dehydration for 4 hours, remove water and toluene, raise the temperature to 160-165°C, polymerize for 48 hours, after the reaction, cool to 120°C, add 2mL N into the three-necked flask, N-dimethylacetamide, dilute the reaction solution, then pour it into 300mL deionized water, wash and desalt, and bake at 100-120°C for 12 hours to obtain 1.302g polyarylene sulfide sulfone containing phthalazinone structure, The yield was 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com