Method for preparing cellulose nano crystal by using acidic eutectic solvent through hydrolysis

A low eutectic solvent and nanocrystal technology, applied in the field of preparation of natural polymer materials, can solve the problems of complicated overall steps, low yield, low thermal stability of products, etc. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

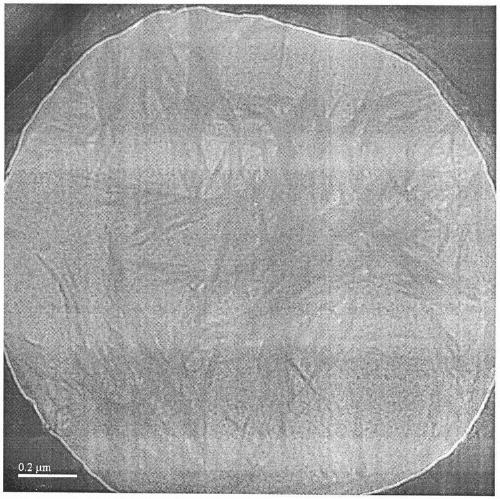

Image

Examples

Embodiment 1

[0018] Add 40g of oxalic acid dihydrate and 45g of choline chloride into a 250mL three-necked flask at 25°C, and add 5g of distilled water to it, then heat it with an oil bath, raise the temperature to 55°C, and stir mechanically for 10min at a speed of 100 r / min to form a deep eutectic solvent, then add 5 g of sulfuric acid with a mass concentration of 98% to the there-necked flask, stir for 5 min, then add 1 g of bleached eucalyptus pulp, continue stirring for 1 h at 55 ° C, and use 300 g of 90 Dilute the reaction mixture with distilled water at ℃, then centrifuge at a speed of 10000r / min for 5min while it is hot, pour out the supernatant and keep the precipitate, then disperse the obtained precipitate with 100g of distilled water, and centrifuge at a speed of 10000r / min for 5min , repeating the process of centrifugal washing with distilled water three times, and freeze-drying the solid obtained after washing, the yield of cellulose nanocrystals was 76.3%. The temperature at...

Embodiment 2

[0020] Add 40g of oxalic acid dihydrate and 50g of choline chloride into a 250mL three-necked flask at 25°C, add 5g of distilled water into it, then heat it with an oil bath, raise the temperature to 45°C, stir mechanically for 10min, and the stirring speed is 300r / min to form a deep eutectic solvent, then add 10g of sulfuric acid with a mass concentration of 98% to the there-necked flask, stir for 5min, then add 10g of dissolving slurry, continue to stir at 45°C for 2h, and use 700g of 60°C distilled water to dissolve the reaction Dilute the mixture, then centrifuge at 10000r / min for 5min while it is hot, pour out the supernatant and keep the precipitate, then disperse the obtained precipitate with 800 g of distilled water, then centrifuge at 10000r / min for 5min, repeat this process The washing process was centrifuged with distilled water for 5 times, and the solid obtained after washing was freeze-dried, and the yield of the obtained nanocellulose crystal was 71.5%. The tem...

Embodiment 3

[0022] Add 40g of oxalic acid dihydrate and 40g of choline chloride into a 250mL three-necked flask at 30°C, add 10g of distilled water into it, then heat it with an oil bath, raise the temperature to 60°C, stir mechanically for 5min, and the stirring speed is 200 r / min to form a deep eutectic solvent, then add 10g of sulfuric acid with a mass concentration of 98% to the there-necked flask, stir for 5min, then add 3g of cotton pulp, continue to stir at 60°C for 1h, and use 300g of 65°C distilled water to Dilute the reaction mixture, then centrifuge at a speed of 8000r / min for 5min while it is hot, pour out the supernatant and keep the precipitate, then disperse the precipitate with 600g of distilled water, then centrifuge at a speed of 8000r / min for 5min, repeat this process The process of washing with distilled water was centrifuged for 5 times, and the solid obtained after washing was spray-dried, and the yield of the obtained nanocellulose crystal was 68%. The temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com