Full-automatic groove breaking necking machine

A fully automatic, shrinking technology, applied in the direction of grinding/polishing safety devices, grinding machines, metal processing equipment, etc., can solve the problems of pipe curling, processing materials scrapping, affecting construction progress, etc., to improve quality and improve force point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

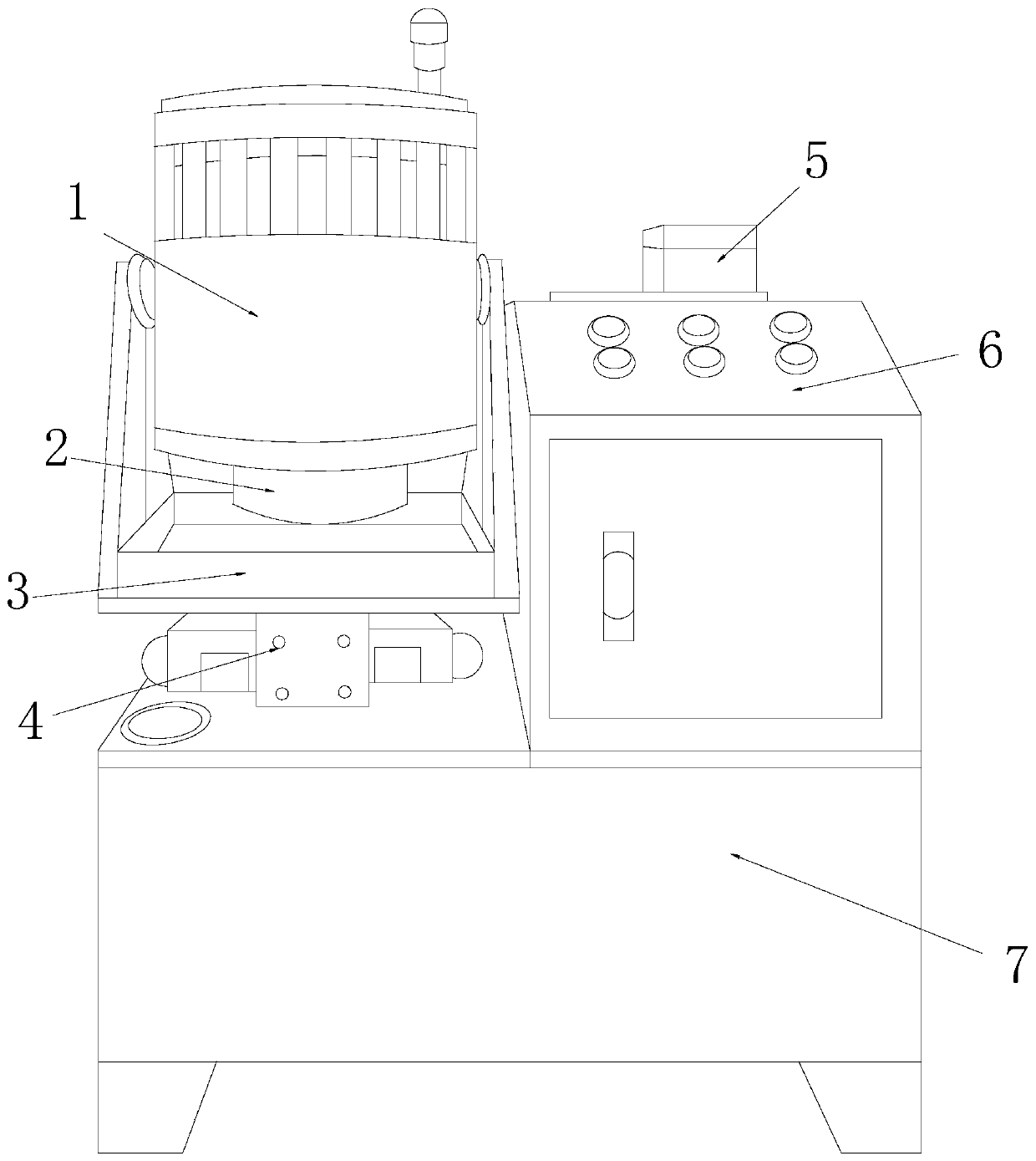

[0032] see Figure 1-Figure 6, the present invention provides a fully automatic groove breaking and shrinking machine, the structure of which includes: a groove breaking and shrinking cylinder 1, a shrinking groove 2, a loading platform 3, an electromagnetic valve seat 4, a relay 5, an electric control box 6, The transmission case 7, the broken groove shrinking cylinder 1 is nested on the top of the shrinking groove 2 and communicates with each other, the broken groove shrinking cylinder 1 is collinear with the axis of the shrinking groove 2, and the broken groove The shrinking cylinder 1 is mechanically connected with the load-carrying platform 3 through the shaft plate, and the said load-carrying platform 3 is installed on the top of the electromagnetic valve seat 4, and the electromagnetic valve seat 4 and the electric control box 6 are respectively installed in the transmission case 7, the relay 5 is nested on the top of the electric control box 6, the electric control box...

Embodiment 2

[0038] see Figure 1-Figure 6 , the present invention provides a kind of full-automatic groove breaking and shrinking machine, other respects are identical with embodiment 1, difference is:

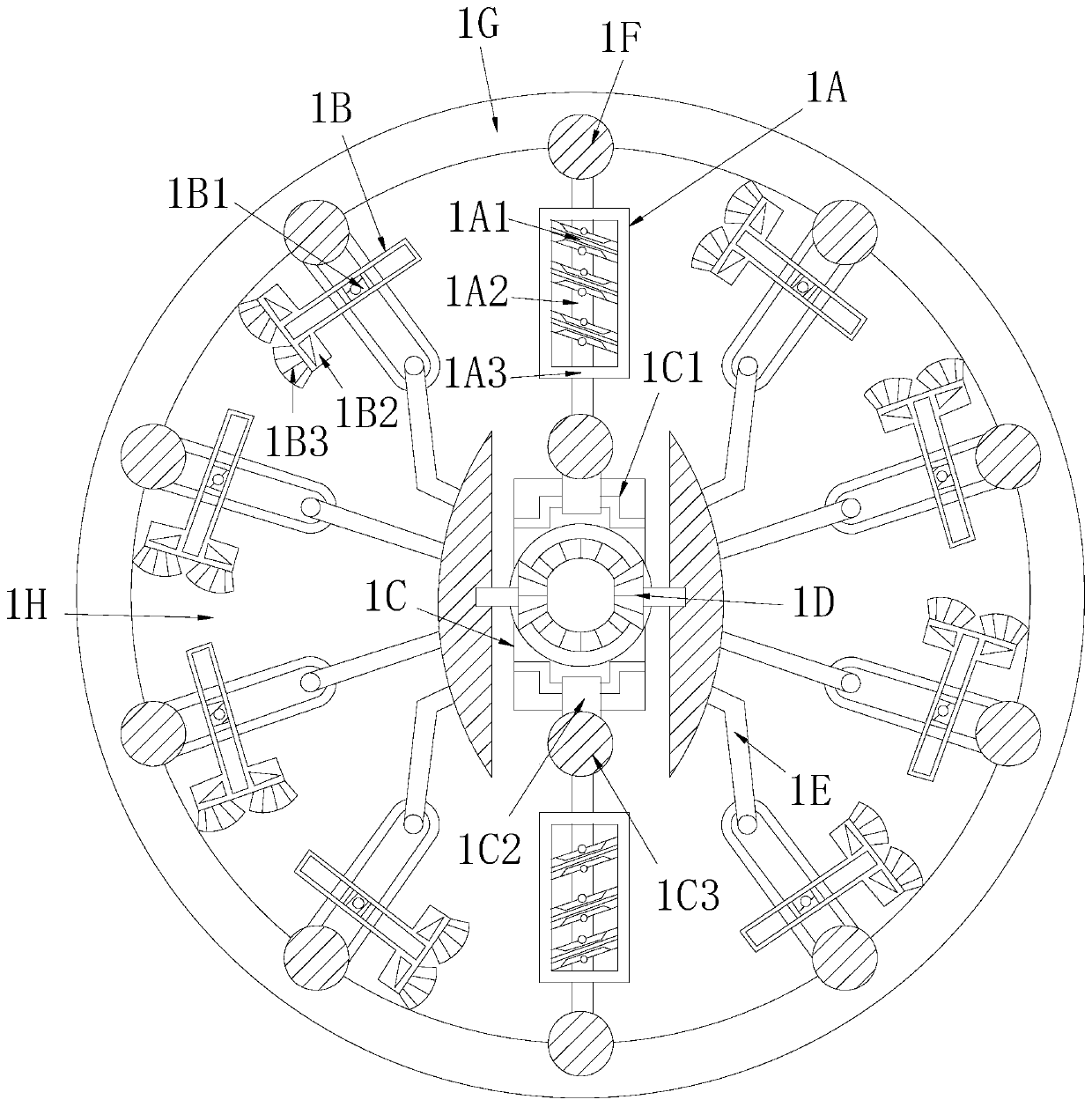

[0039] see figure 2 , the nozzle fine-tuning frame 1C is composed of a hammer press wheel frame groove 1C1, a short buckle ring block 1C2, and a lock wheel groove 1C3, and the hammer press wheel frame groove 1C1 is mechanically connected to the lock wheel groove 1C3 through the short buckle ring block 1C2 and the lock wheel groove 1C3. Connected and located on the same vertical plane, the short clasp block 1C2 and the lock wheel groove 1C3 are provided with two and installed on the upper and lower sides of the hammer wheel frame groove 1C1 respectively, and inserted through the hammer wheel frame groove 1C1 The short buckle block 1C2 forms the effect of vertical counterweight lowering the nested nozzle, which facilitates the positioning of the retracted nozzle and ensures the uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com