Surface conformal circuit direct writing device based on laser sintering principle

A technology of laser sintering and curved surface, which is applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc. It can solve the problems of direct writing process limitations, difficult maintenance and complicated operation of microelectronic components, and achieve the difficulty and cost of operation and maintenance The effect of low, high movement accuracy, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

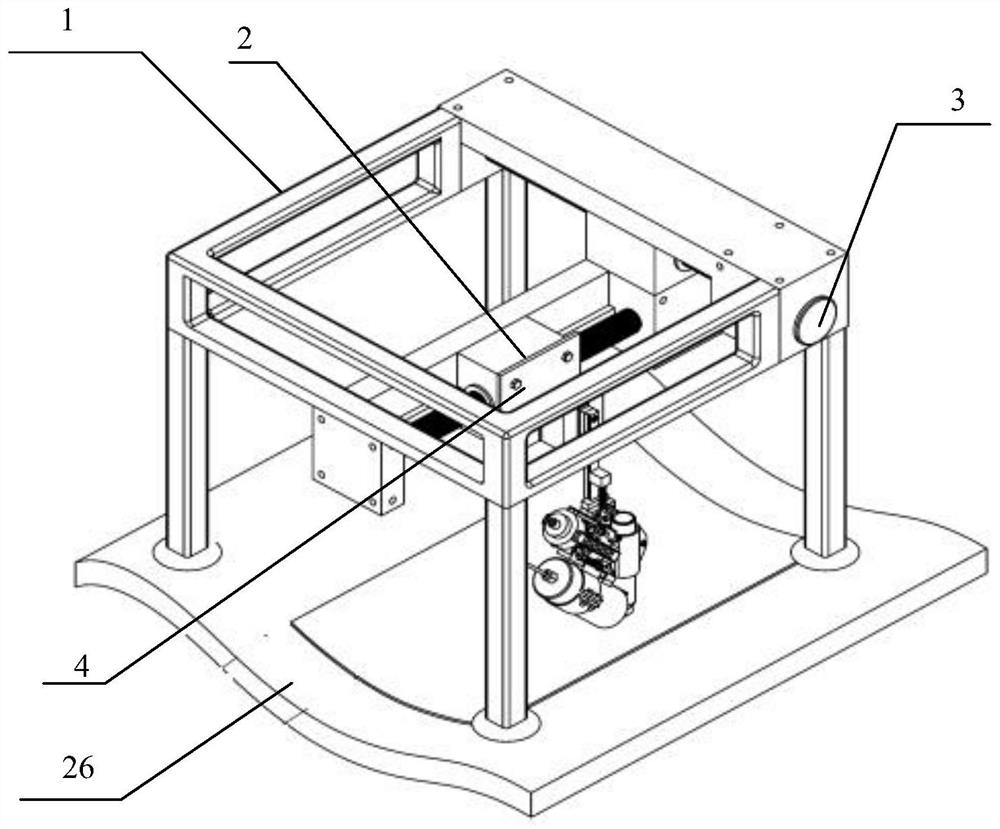

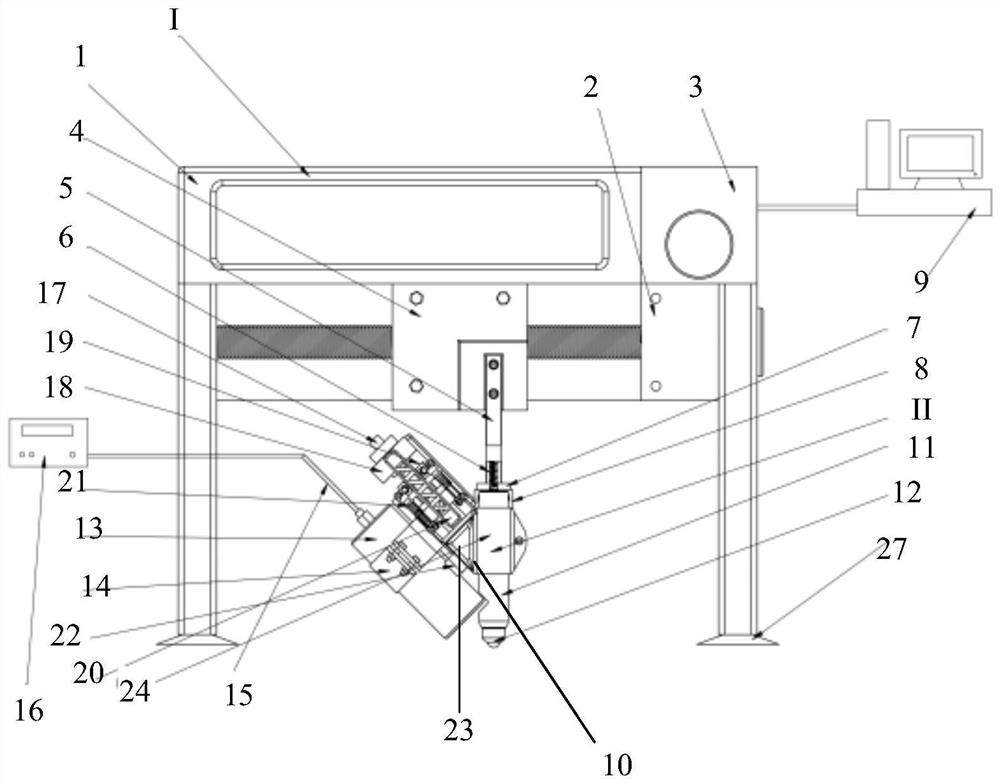

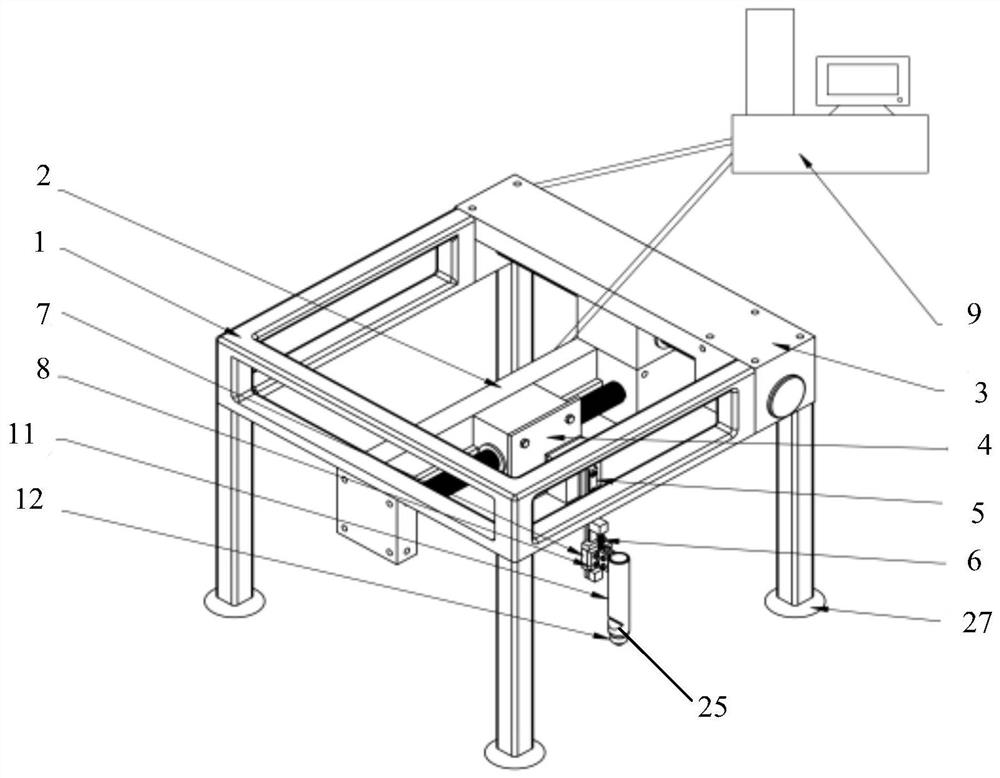

[0041] Such as Figure 1-3 As shown, the embodiment of the present invention provides a curved surface conformal circuit direct writing device based on the principle of laser sintering, the device includes: curved surface conformal traveling mechanism I and laser output mechanism II;

[0042] The curved surface conformal walking mechanism Ⅰ includes bracket 1, X-axis stepping motor screw 2, Y-axis stepping motor screw 3, Z-axis fixed parts 4, linear guide rail 5, Z-axis spring 6, Z-axis slider 7, slide Block connector 8, universal ball traveling unit and motor drive device;

[0043] Wherein, the bracket 1 is processed by a numerical control machine tool, and its material includes but not limited to metal materials such as aluminum alloy and stainless steel. The bracket 1 can be fixed on a certain plane through a vacuum suction cup 27 structure (the curved substrate 26 to be directly written is arranged on the universal ball The bottom of the walking unit), which makes the dis...

specific Embodiment 2

[0059] Such as Figure 5 As shown, in this embodiment, the circuit direct writing device and the copper nitrate precursor solution in the specific embodiment 1 are used for direct circuit writing, and the process is as follows:

[0060] Step 1, take by weighing 12.08g copper nitrate trihydrate (Cu(NO3) 2 3H2O), dissolved in 10ml deionized water, and ultrasonically oscillated until fully dissolved; the configuration method of polyvinylpyrrolidone aqueous solution is: weigh 2.5g polyvinylpyrrolidone (PVP, K23~K27), dissolve in 10ml In deionized water, ultrasonically oscillate until fully dissolved; the preparation method of polyethylene glycol aqueous solution is: weigh 2.5g of polyethylene glycol (PEG-6000), dissolve it in 10ml of deionized water, and ultrasonically oscillate until fully dissolved;

[0061] Step 2, 200 μ l of the copper nitrate aqueous solution that got, 150 μ l of the polyvinylpyrrolidone aqueous solution that got, and 150 μ l of the polyethylene glycol aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com