Processing method of sound hole of MEMS carrier plate

A processing method and sound hole technology, which is applied in the field of sound hole processing, can solve problems such as the deterioration of sound hole and graphic accuracy, affect the quality of sound holes, and waste costs, so as to improve processing accuracy, control the quality and roughness of sound holes controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

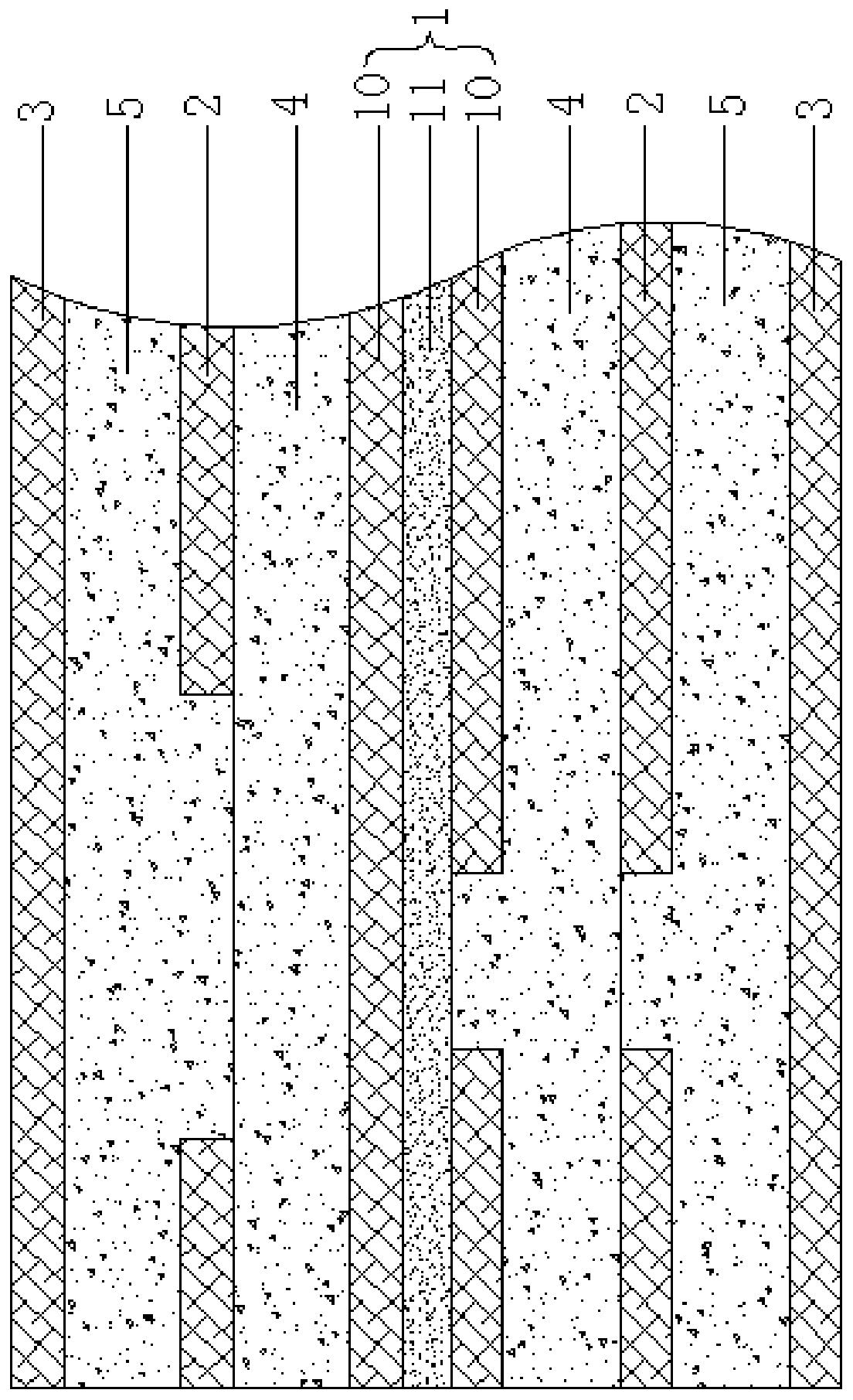

[0026] The invention provides a method for processing an acoustic hole of a MEMS carrier board, comprising the following steps: step 1), preparing a MEMS carrier board, for details, please refer to the attached figure 1 As shown, the MEMS carrier board includes a core board 1, two first copper layers 2 and two second copper layers 3, wherein the core board 1 is composed of two inner copper layers 10 through an inner insulating layer in the middle 11 by pressing and compounding, the two first copper layers 2 are respectively laminated on the surfaces of the two inner copper layers 10 through a first insulating layer 4, and the two second copper layers 3 are respectively Pressing on the two surfaces of the first copper layer 2 through a second insulating layer 5;

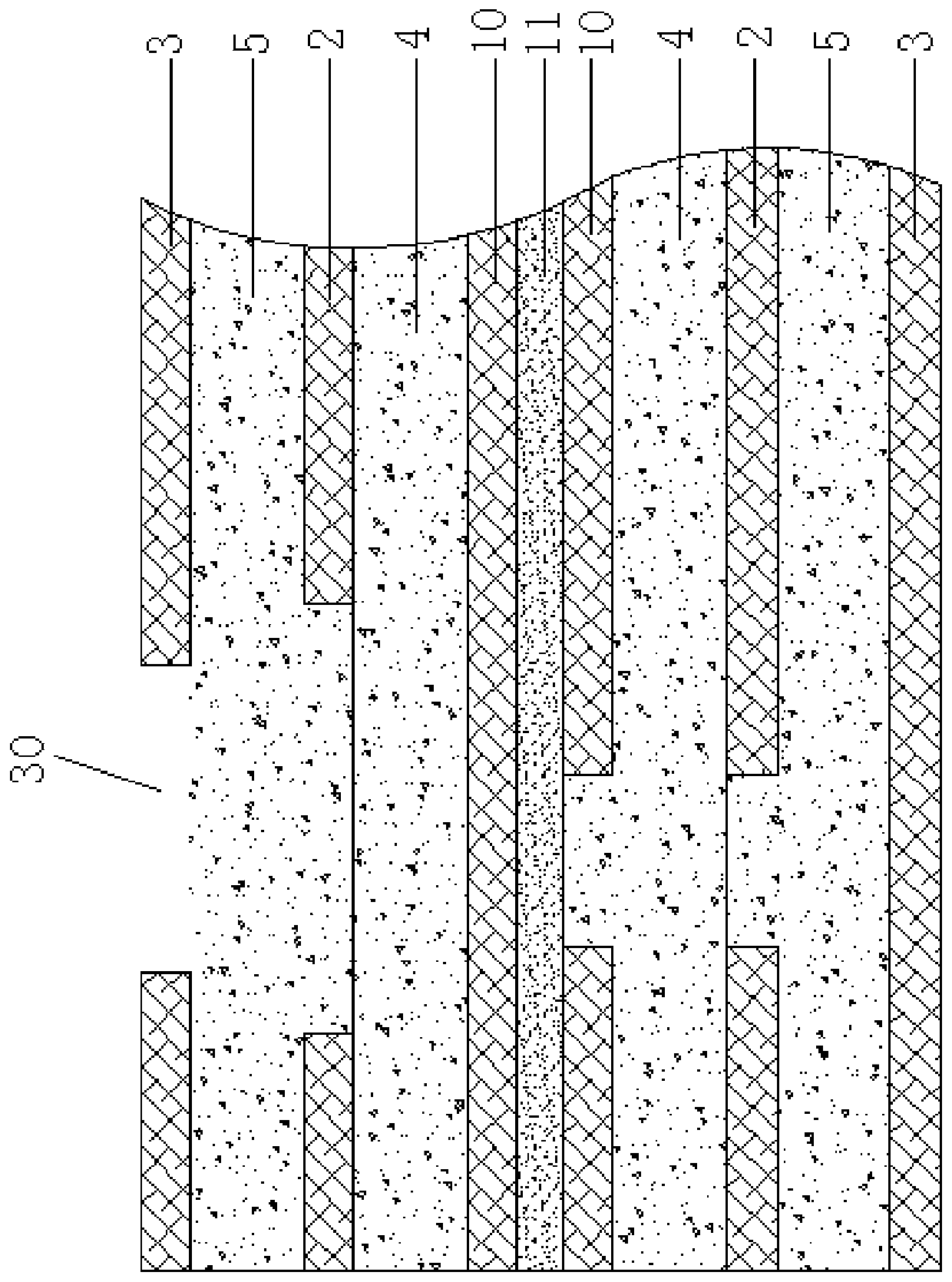

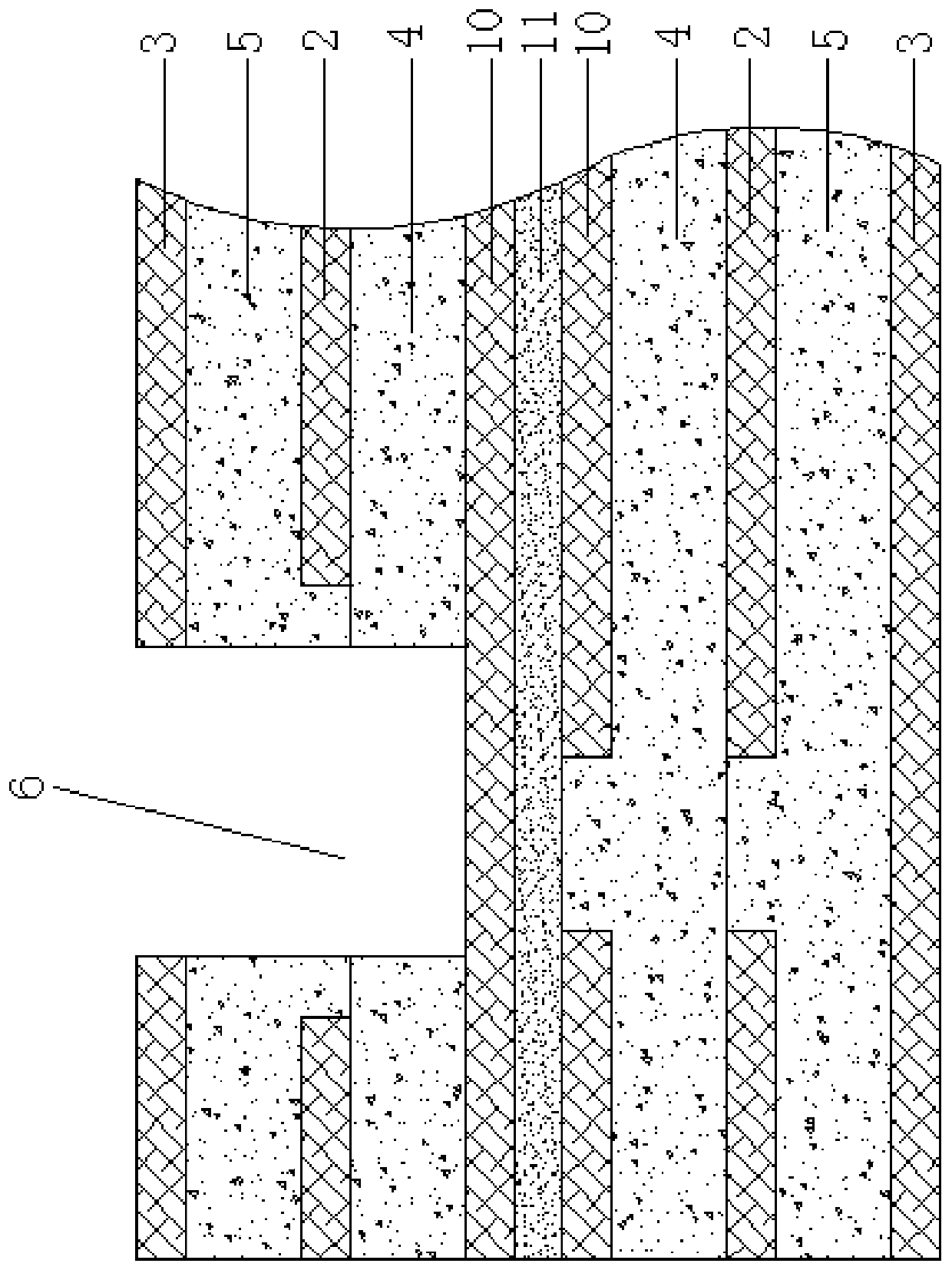

[0027] Step 2), according to the requirements of circuit layout, perform laser window opening operation on the second copper layer 3 to form a window 30 that can expose part of the surface of the second insulating lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Slot length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com