Chemical storage tank steam cloud explosion accident simulation analysis method and system

A simulation analysis, steam technology, applied in design optimization/simulation, special data processing applications, computer-aided design, etc., can solve problems such as neglect of liquid pool evaporation process, steam cloud explosion accident, result deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

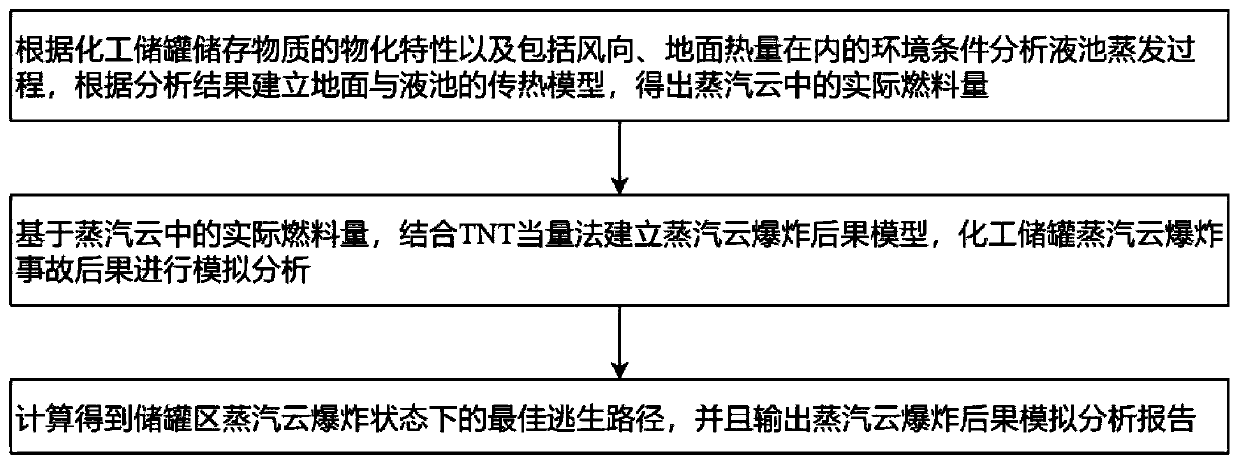

[0074] combine figure 1 , the present invention proposes a chemical storage tank steam cloud explosion accident simulation analysis method, the simulation analysis method includes the following steps:

[0075] S1. Analyze the evaporation process of the liquid pool according to the physical and chemical characteristics of the materials stored in the chemical storage tank and the environmental conditions including wind direction and ground heat. Based on the analysis results, a heat transfer model between the ground and the liquid pool is established to obtain the actual amount of fuel in the vapor cloud. .

[0076] S2, based on the actual amount of fuel in the steam cloud, combined with the TNT equivalent method to establish a steam cloud explosion consequence model, and conduct a simulation analysis of the chemical storage tank steam cloud explosion accident consequences.

[0077] S3, calculate the optimal escape path under the steam cloud explosion state in the storage tank ...

specific Embodiment 2

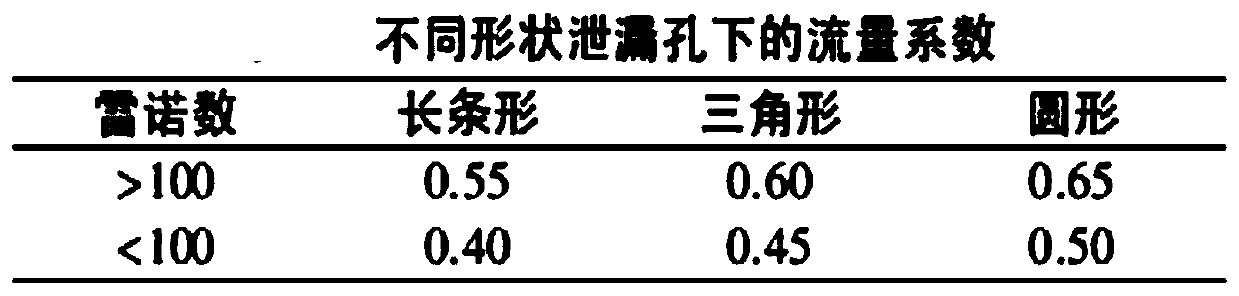

[0135] Assuming that the LNG storage tank is a single-capacity tank with a height of 25.5m, an outer diameter of 43.5m, and an inner diameter of 41.5m, the filling factor is 85%, and the combustion heat of LNG vapor is 55594KJ / kg. Assuming that the shape of the LNG leakage port is circular, the area of the small hole is A=0.05m2, and the Reynolds coefficient image 3 The flow coefficient found in the flow coefficient chart Re-Cd is 0.50, and the density of LNG is ρ L =450kg / m3, atmospheric pressure p 0 =10100Pa, the pressure in the container is p=110Pa, the acceleration of gravity is taken as the standard value g=9.80665 m / s^2, assuming that the initial liquid level of the leak is h=15m from the height of the leak. Assume that the pressure does not change throughout the leak.

[0136] The concrete steps of adopting the method of the present invention are as follows:

[0137] 1. Calculate the total evaporation of the liquid substance in the storage tank during the evaporatio...

specific Embodiment 3

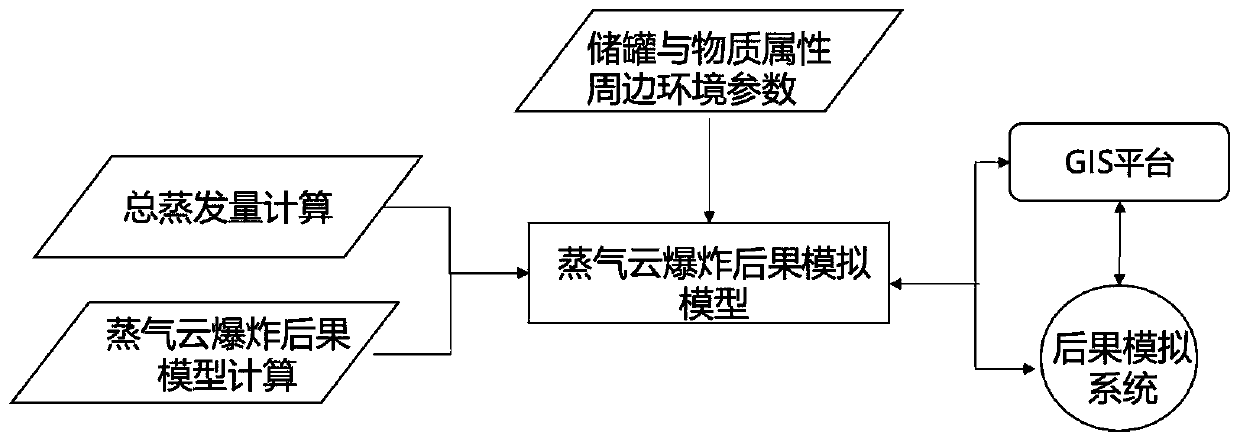

[0158] Such as figure 2 As shown, the present invention also mentions a chemical storage tank steam cloud explosion accident simulation analysis system, which includes a parameter acquisition module, a total evaporation calculation module, a steam cloud explosion consequence model and a steam cloud explosion consequence simulation model.

[0159] The parameter acquisition module is used to acquire in real time the physical and chemical characteristics of the material stored in the chemical storage tank and the environmental conditions including wind direction and ground heat. Preferably, the physical and chemical characteristics of the stored material in the chemical storage tank and the environmental conditions including wind direction and ground heat include: the height, outer diameter, inner diameter of the storage tank, operating pressure, liquid material density, filling coefficient, wind direction, ground type, Ambient pressure, ambient average wind speed and other para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com