Nano SiO2 coated BN composite powder, preparation method thereof and thermal conductive material

A composite powder and coating technology, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of limited improvement of thermal conductivity of thermally conductive functional materials, affecting the thermal conductivity of boron nitride, and limited improvement of compatibility. To achieve excellent thermal conductivity, promote the cost of preparation, and the effect of rapid heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1). Put 60g of spherical boron nitride into a 2000mL three-necked flask, add 150mL of water, 600mL of absolute ethanol and 0.075g of cetyltrimethylammonium bromide (CTAB), and implement ultrasonic dispersion for 30min;

[0037] (2). Inject 4ml of ammonia water into the three-necked flask and raise the temperature to 40°C;

[0038] (3). Mix anhydrous ethanol and TEOS, and add the mixture dropwise to the three-necked flask three times, each time adding one-third of the total volume of the mixture, after each drop, stir for 1 hour, and then proceed to the next drop Add; continue to react for 10h after the dropwise addition of all the mixed solution is completed;

[0039] The mass ratio of the spherical BN, CTAB, TEOS, water and ETOH is 2:0.0025:1.3:5:27;

[0040] (4). Let the above-mentioned reactants stand for precipitation. After the upper layer appears turbid liquid, tilt the three-necked flask, pour out the upper layer of turbid liquid, and then wash the lower layer wi...

Embodiment 2

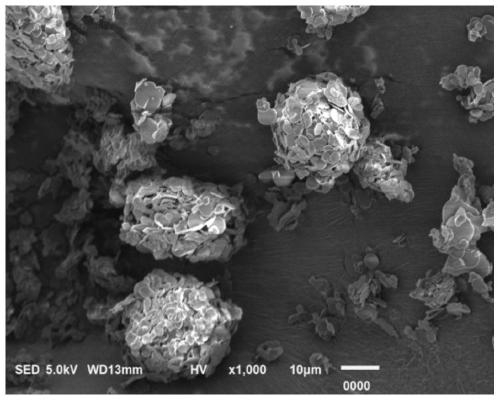

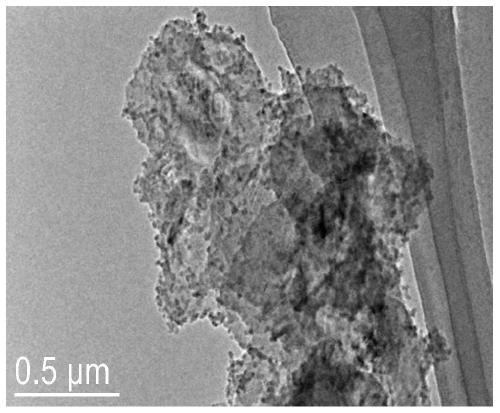

[0042] The preparation method is the same as in Example 1, except that no surfactant is added in step ①, and the mass ratio of spherical BN, TEOS, water and ETOH is 2:1.3:5:27; image 3 As shown, the SiO on the surface of spherical BN particles 2 The thickness of the cladding layer is uneven, and there is obvious agglomeration and stacking.

Embodiment 3

[0044] The preparation method is the same as in Example 1, and the mass ratio of spherical BN, CTAB, TEOS, water and ETOH is 2:0.01:1.3:5:27;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com