Self-cleaning spraying rubber asphalt waterproof system and preparation method thereof

A rubber asphalt, self-cleaning technology, used in asphalt coatings, devices for coating liquid on surfaces, coatings, etc. problems, to avoid pollution, solve the problem of anti-freezing, and improve the effect of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

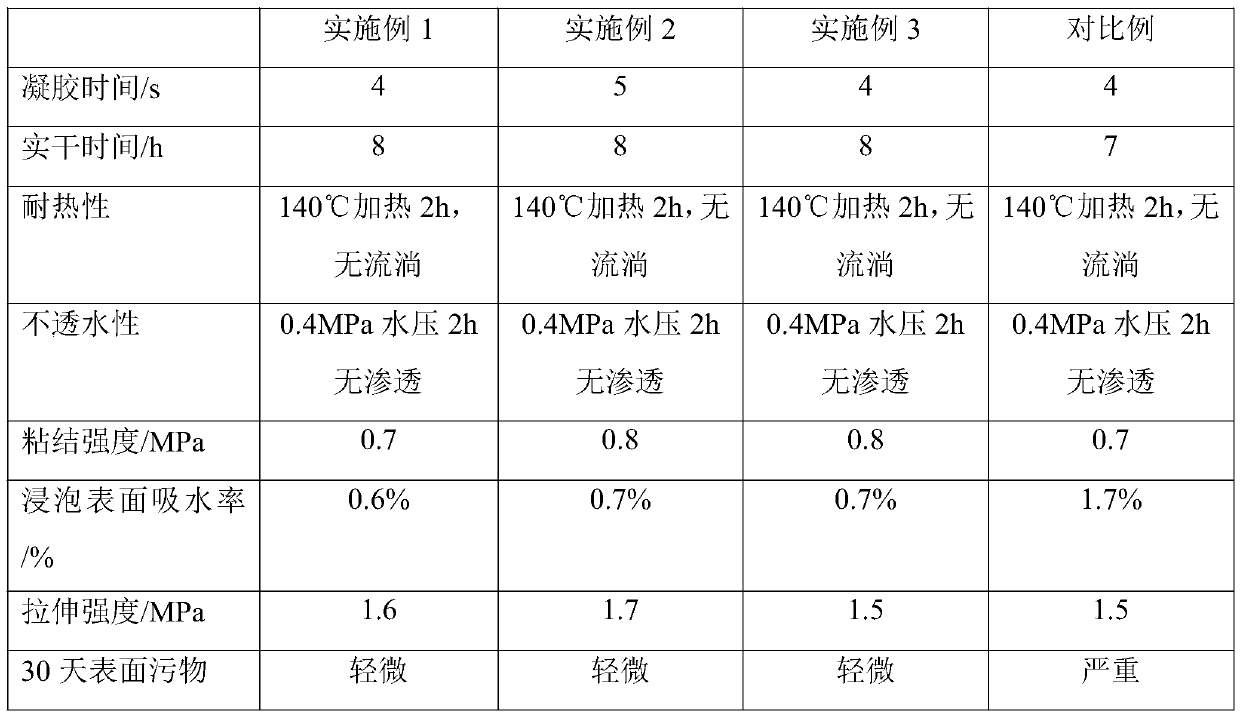

Examples

Embodiment 1

[0039] First, prepare spray rubber asphalt composite material: take 54 parts of anionic emulsified asphalt, 50 parts of chloroprene latex LIPRENB, 0.5 parts of defoamer and 10 parts of triaryl phosphate, stir and mix for 30 minutes to obtain rubber asphalt components. A curing agent component was obtained by dissolving 10 parts of calcium chloride in 90 parts of water to obtain a 10% aqueous solution of calcium chloride.

[0040] Next, prepare the superhydrophobic polyurethane coating solution: 43 parts of polypropylene oxide polyol and 12 parts of hydroxyalkyl modified silicone Tech-2110 are vacuum dehydrated at 110 ° C, and 25 parts of isophorone diisocyanate IPDI are added after cooling down React with 0.025 parts of dibutyltin dilaurate, stop the reaction when w(NCO) is lower than 6.1%, and obtain a polyurethane prepolymer. Take 4 parts of nano-silica with a particle size of 7nm, 6 parts of polyurethane prepolymer, and 90 parts of ethyl acetate, and oscillate evenly in an ...

Embodiment 2

[0043] First, prepare the spray rubber asphalt combination: take 50 parts of anionic emulsified asphalt, 40 parts of neoprene latex LIPRENB, 7 parts of styrene-butadiene latex KSL 341, 0.2 parts of defoamer, 3 parts of triaryl phosphate and 12 parts of magnesium hydroxide, Stir and mix for 30 minutes to obtain rubber asphalt components. The curing agent component was obtained by dissolving 10 parts of zinc sulfate in 90 parts of water to obtain a 10% zinc sulfate aqueous solution.

[0044] Next, prepare a superhydrophobic polyurethane coating solution: 40 parts of polypropylene oxide polyol and 20 parts of hydroxyalkyl modified silicone Tech-2120 are vacuum dehydrated at 110°C, and 18 parts of 4,4-dicyclohexyl Methane diisocyanate HMDI reacts with 0.03 parts of dibutyltin dilaurate, and stops the reaction when w(NCO) is lower than 4.2%, to obtain a polyurethane prepolymer. Take 4 parts of nano-silica with a particle size of 12nm, 10 parts of polyurethane prepolymer, 60 parts ...

Embodiment 3

[0047] First, prepare spray rubber asphalt combination: get 40 parts of anionic emulsified asphalt, 30 parts of chloroprene latex, 10 parts of styrene-butadiene latex KSL 341, 0.5 part of defoamer, 5 parts of tris(2-chloropropyl) phosphate and 5 parts part of antimony trioxide, and stirred and mixed for 30 minutes to obtain rubber asphalt components. A curing agent component was obtained by dissolving 10 parts of calcium nitrate in 90 parts of water to obtain a 10% aqueous solution of calcium nitrate.

[0048] Next, prepare the superhydrophobic polyurethane coating solution: 45 parts of polypropylene oxide polyol and 8 parts of hydroxyalkyl modified silicone Tech-2110 are vacuum dehydrated at 110°C, and 10 parts of cyclohexane dimethylene are added after cooling down Diisocyanate HXDI reacts with 0.015 parts of dibutyltin dilaurate, and stops the reaction when w(NCO) is lower than 2.8%, to obtain a polyurethane prepolymer. Take 5 parts of nano-silica with a particle size of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com