Anti-protein adsorption self-cleaning block copolymer, preparation method and application thereof

A block copolymer, anti-protein adsorption technology, applied in the preparation methods of peptides, chemical instruments and methods, production of bulk chemicals, etc., can solve the problems of protein adsorption and cleaning difficulties of coating materials, etc. Solve the effect of coating cleaning, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing an anti-protein adsorption self-cleaning block copolymer, comprising the following steps:

[0045] S1. Under the protection of nitrogen atmosphere, add 2-bromoisobutyryl bromide BIBB, triethylamine ETA and lutidine DMAP into an appropriate amount of organic solvent dichloromethane DCM, stir and dissolve and place in an ice-water bath to obtain Mixed solution B; mixed polyethylene glycol monomethyl ether PEO and DCM in a mass ratio of 1:(3~5) to obtain mixed solution C, then added mixed solution C dropwise to mixed solution B, and reacted at room temperature for 10~ 20h, extract three times with NaCl solution, dry the organic phase over anhydrous magnesium sulfate, filter, and rotate to remove the solvent, the product is settled in glacial ether, filtered and dried in vacuum to obtain a light yellow macroinitiator PEO-Br; among which PEO is preferred for PEO 2000 ;

[0046] S2. Add the initiators PEO-Br, NIPAAm...

Embodiment 1

[0060] The preparation method of the anti-protein adsorption self-cleaning block copolymer provided in this embodiment comprises the following steps:

[0061] S1. Add 1.22g DMAP, 1.24ml BIBB, 1.4ml TEA and 15ml DCM to a 150ml three-necked flask, stir and dissolve in an ice-water bath, under nitrogen protection, add 10g PEO dropwise with a constant pressure dropping funnel 2000 50 ml of DCM solution was slowly stirred at room temperature for 12 h. After the reaction was completed, it was extracted three times with NaCl solution, the organic phase was dried over anhydrous magnesium sulfate, filtered, and the solvent was removed by rotary evaporation. The product was precipitated in glacial ether, filtered and dried in vacuum for 12 hours to obtain a light yellow ATRP macroinitiator PEO 2000 -Br.

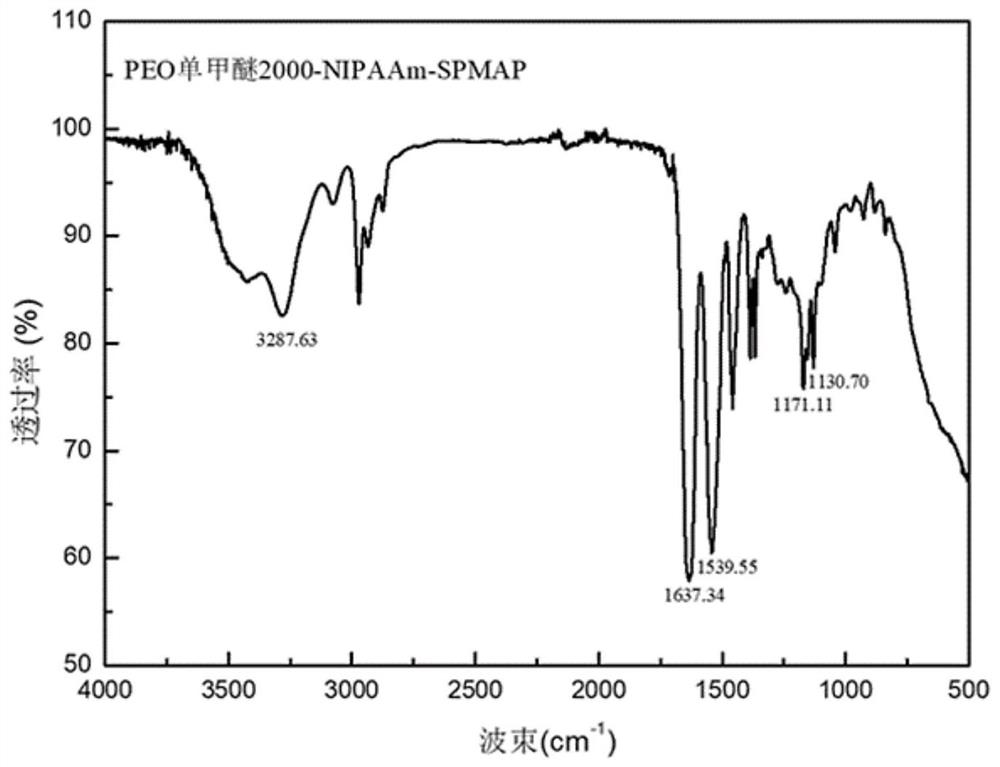

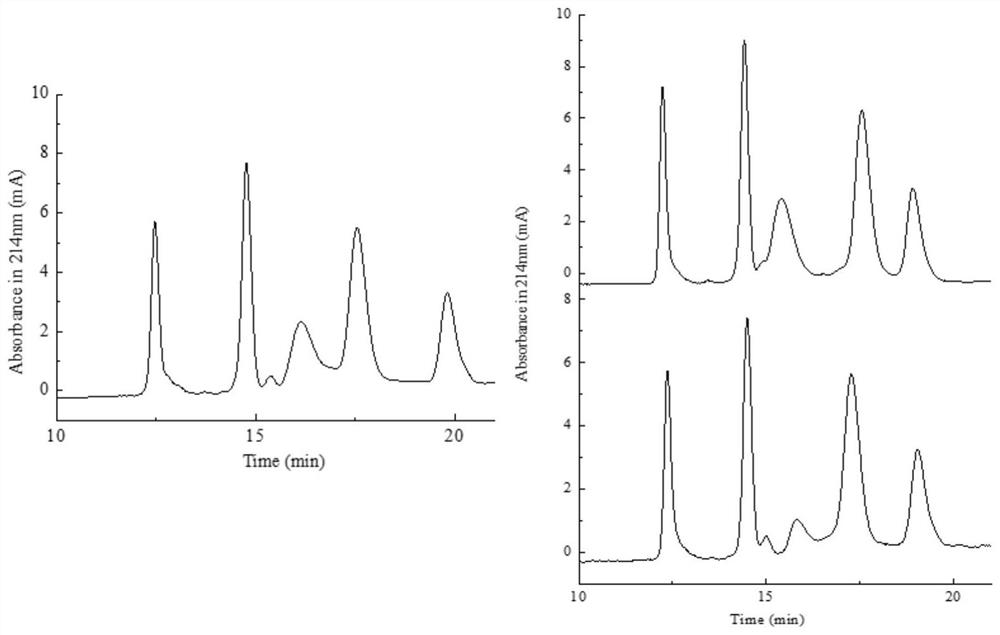

[0062] S2, the initiator prepared in step S1 0.5g PEO 2000 -Br, 2.2632g NIPAAm, 0.043g PMDETA were added to a 150ml three-necked flask, and 10ml of dimethylformamide DMF and H were a...

Embodiment 2

[0066] The preparation method of the anti-protein adsorption self-cleaning block copolymer provided in this embodiment comprises the following steps:

[0067] S1. Add 1.22g DMAP, 1.24ml BIBB, 1.4ml TEA and 15ml DCM into a 150ml three-necked flask, stir and dissolve in an ice-water bath, under nitrogen protection, add 25g PEO dropwise with a constant pressure dropping funnel 5000 50 ml of DCM solution was slowly stirred at room temperature for 12 h. After the reaction was completed, it was extracted three times with NaCl solution, the organic phase was dried over anhydrous magnesium sulfate, filtered, and the solvent was removed by rotary evaporation. The product was precipitated in glacial ether, filtered and dried in vacuum for 12 hours to obtain a light yellow ATRP macroinitiator PEO 5000 -Br.

[0068] S2, the initiator prepared in step S1 1.25g PEO 5000 -Br, 2.663g NIPAAm, 0.043g PMDETA were added to a 150ml three-necked flask, and 10ml of dimethylformamide DMF and H were...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com