Preparation method of supported cigarette butt porous carbon material catalyst and application of supported cigarette butt porous carbon material catalyst in nitrocyclohexane hydrogenation reaction

A technology of porous carbon material and nitrocyclohexane, which is applied to the preparation of a supported cigarette butt porous carbon material catalyst, and the application field in the hydrogenation reaction of nitrocyclohexane, can solve the problems of high cost, environmental pollution, flammability and easy flammability. Explosive storage environment and other problems, to achieve the effect of improving conversion rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

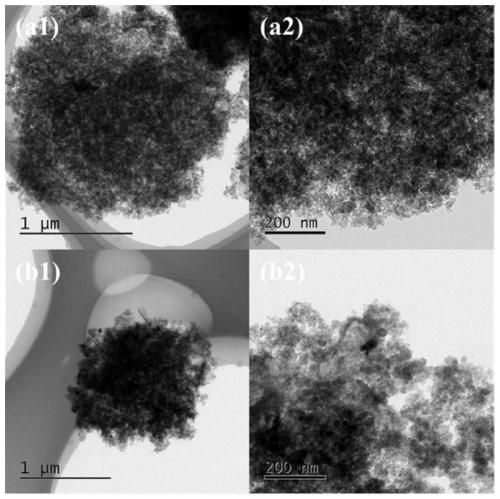

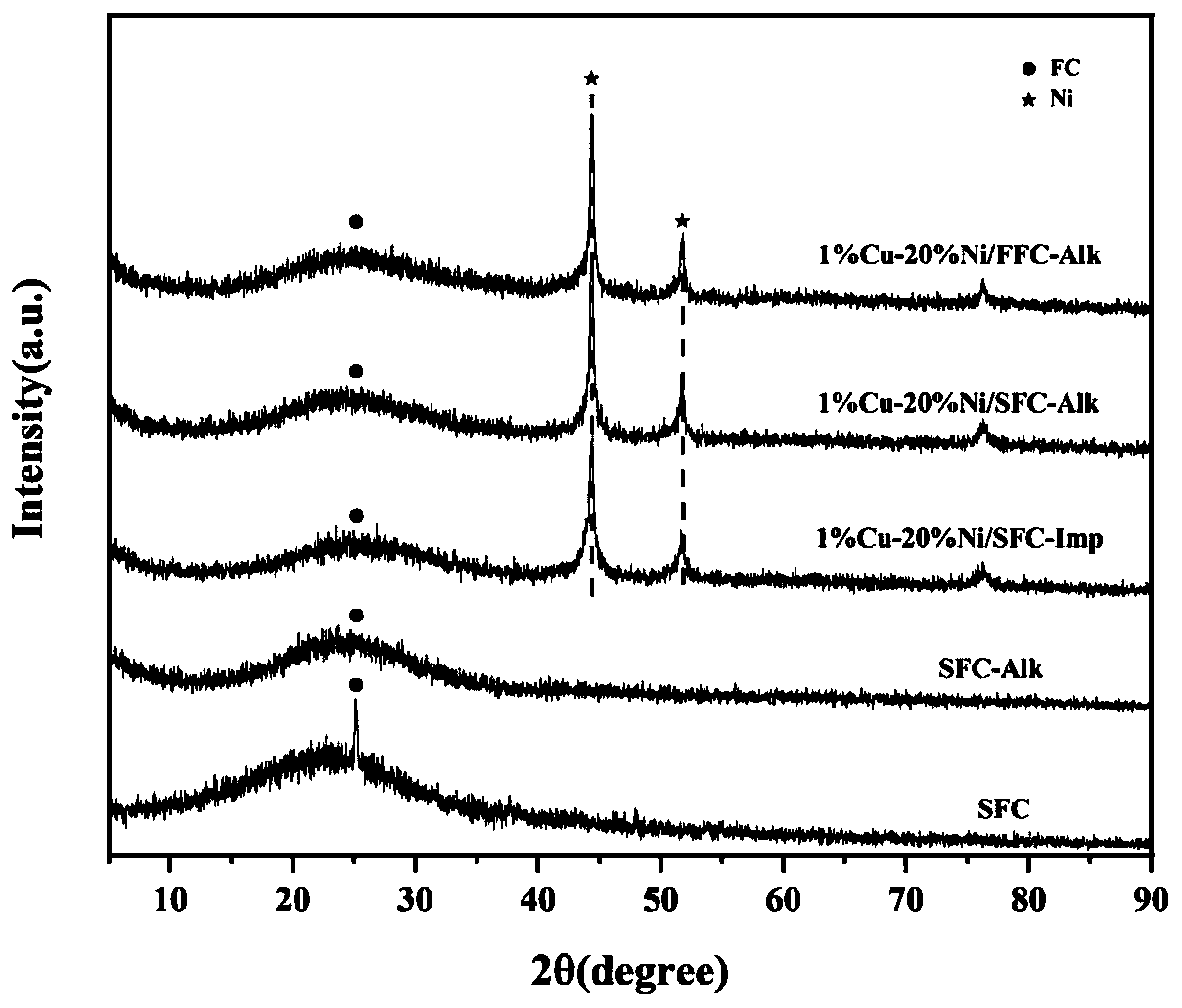

[0036]Weigh 10g of used cigarette butts, put them in a beaker, add concentrated nitric acid according to the solid-liquid mass ratio of 1:5, stir and soak at room temperature for 2 hours, remove the ash on the surface of the cigarette butts, and add deionized Water, stirred and soaked at room temperature for 24 hours, and moved into a crystallization kettle, carbonized with high-temperature and high-pressure water at 300°C for 2 hours, after natural cooling, suction-filtered the suspension, washed with distilled water until neutral, and dried at 110°C for 12 hours to obtain Cigarette butt porous carbon material precursors have been used. Weigh 3 g of the porous carbon material precursor of the used cigarette butt and 15 g of potassium hydroxide, place it in a quartz boat, and activate it by roasting in a nitrogen atmosphere. ℃, roasted at 900°C for 3 hours under the protection of nitrogen in the second stage, and then naturally cooled to room temperature under the protection o...

Embodiment 2

[0038] Weigh 0.12g of the 1%Cu-20%Ni / SFC-Alk catalyst obtained in Example 1 and place it in a 50mL lining of a high-temperature reactor, add 0.5g of nitrocyclohexane, 5.2g of ethylenediamine, and put , seal the autoclave, replace the air in the autoclave with hydrogen for 4 times, evacuate the autoclave to a vacuum with a vacuum pump, and then place the autoclave in a heating jacket. After rising to the set reaction temperature of 100°C, hydrogen gas was introduced to pressurize to 0.3MPa, magnetic stirring was started, and the reaction timing started. After reacting for 8 hours, the reaction mixture was filtered, and the content of each substance in the filtrate was analyzed by gas chromatography. The conversion rate of nitrocyclohexane was 99.36%, the selectivity of cyclohexanone oxime was 90.66%, and the selectivity of cyclohexylamine was 9.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com