Preparation method of alumina-zirconia composite coating on surface of high-thermal-conductivity carbon fiber

A composite coating and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve problems such as cracks and peeling off of the coating, failure to meet energy saving requirements, and affect the application of carbon fiber, etc., to achieve low toxicity and low toxicity , easily accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

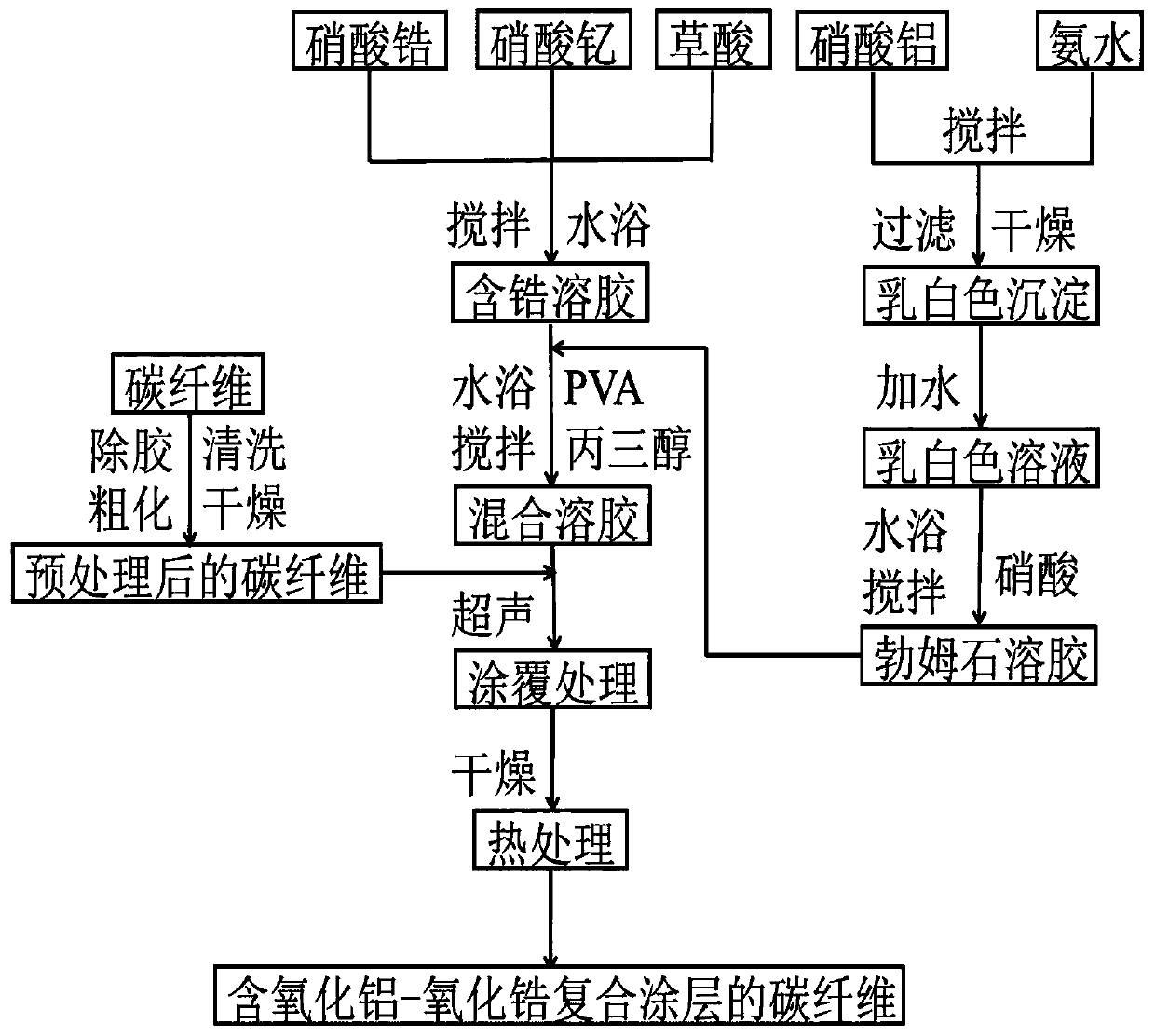

Method used

Image

Examples

Embodiment 1

[0043] Place the carbon fiber in a tube furnace, keep it warm at 400°C for 20min, soak it in acetone for 1h after cooling to completely remove the glue, then wash it with deionized water, and dry it in vacuum at 80°C for 3h.

[0044] Mix zirconium nitrate and yttrium nitrate at a molar ratio of 97:3, add deionized water to form a 1 mol / L zirconium nitrate solution, add dropwise a 1mol / L oxalic acid solution, and add dropwise at a molar ratio of zirconium nitrate and oxalic acid of 4.5:1, Add 423ml of deionized water and keep stirring for 30min, add 13g of polyvinyl alcohol and 13g of glycerol, and then put it in a water bath at 95°C and keep stirring for 40min to obtain a blue transparent zirconium-containing sol with a concentration of 0.3mol / L ;Mix 3mol / L ammonia solution and 1mol / L aluminum nitrate solution at a molar ratio of 4:1, and continue to stir for 30 minutes to obtain a solution with milky white precipitate, filter, wash with deionized water several times, and dry a...

Embodiment 2

[0048] The treated carbon fibers were submerged in the sol, ultrasonically impregnated for 5 minutes, the carbon fibers were repeatedly coated and dried twice, and the rest of the process steps and conditions were the same as in Example 1.

[0049] Carbon fibers coated with an alumina-zirconia composite coating are obtained through the above steps, and the thickness of the coating is about 65 nm.

Embodiment 3

[0051] The treated carbon fibers were submerged in the sol, ultrasonically impregnated for 5 minutes, the carbon fibers were repeatedly coated and dried three times, and the rest of the process steps and conditions were the same as in Example 1.

[0052] Carbon fibers coated with an alumina-zirconia composite coating are obtained through the above steps, and the thickness of the coating is about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com