Organic phase change microcapsule, organic phase change microcapsule composite heat dissipation material and preparation method thereof

A technology of composite heat-dissipating materials and microcapsules, applied in the directions of heat exchange materials, chemical instruments and methods, etc., can solve the problems of microcapsules being susceptible to external corrosion, complicated preparation methods, unsatisfactory thermal conductivity, etc., and achieve excellent heat dissipation effect. , The preparation method is simple, and the effect of avoiding the emission of special odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

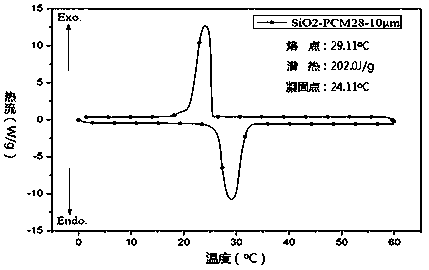

[0034] This embodiment provides an organic phase change microcapsule, an organic phase change microcapsule composite heat dissipation material and a preparation method thereof. The organic phase change microcapsule of this embodiment has a core-shell structure, the core is the capsule core, including paraffin wax component; the shell is the capsule wall, including silicon dioxide component. The organic phase change microcapsules are made into powder by spray drying, and then the organic phase change microcapsule composite heat dissipation material is obtained through aluminum-plastic film packaging. The aluminum-plastic film can protect the organic phase change microcapsules from external erosion and avoid phase change. The leakage of the phase-change microcapsules promotes the safe, convenient and effective use of the phase-change microcapsules.

[0035] The raw materials for the preparation of organic phase change microcapsules and organic phase change microcapsule composite...

Embodiment 2

[0048] This embodiment provides an organic phase change microcapsule, an organic phase change microcapsule composite heat dissipation material and a preparation method thereof. The organic phase change microcapsule of this embodiment has a core-shell structure, the core is the capsule core, including octadecane; the shell is the capsule wall, including silicon dioxide. The organic phase change microcapsules are made into powder by spray drying, and then the organic phase change microcapsule composite heat dissipation material is obtained through aluminum-plastic film packaging. The aluminum-plastic film can protect the organic phase change microcapsules from external erosion and avoid phase change. The leakage of the phase-change microcapsules promotes the safe, convenient and effective use of the phase-change microcapsules.

[0049] The raw materials for preparing the organic phase change microcapsules and organic phase change microcapsule composite heat dissipation materials...

Embodiment 3

[0059] This embodiment provides an organic phase change microcapsule, an organic phase change microcapsule composite heat dissipation material and a preparation method thereof. The organic phase change microcapsule of this embodiment has a core-shell structure, the core is the capsule core, including n-tetradecane component; the shell is the capsule wall, including silicon dioxide component. The organic phase change microcapsules are made into powder by spray drying, and then the organic phase change microcapsule composite heat dissipation material is obtained through aluminum-plastic film packaging. The aluminum-plastic film can protect the organic phase change microcapsules from external erosion and avoid phase change. The leakage of the phase-change microcapsules promotes the safe, convenient and effective use of the phase-change microcapsules.

[0060] The raw materials for the preparation of organic phase change microcapsules and organic phase change microcapsule composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com