Antibacterial and bactericidal material for coating as well as preparation method and application thereof

A coating and raw material technology, applied in the field of antibacterial and sterilizing materials and their preparation, can solve the problems of short anti-aging period, easy to attach dust, and easy aging of coatings, and achieve improved antibacterial and sterilizing performance and anti-aging performance, good antibacterial and sterilizing properties Effect, excellent effect of anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

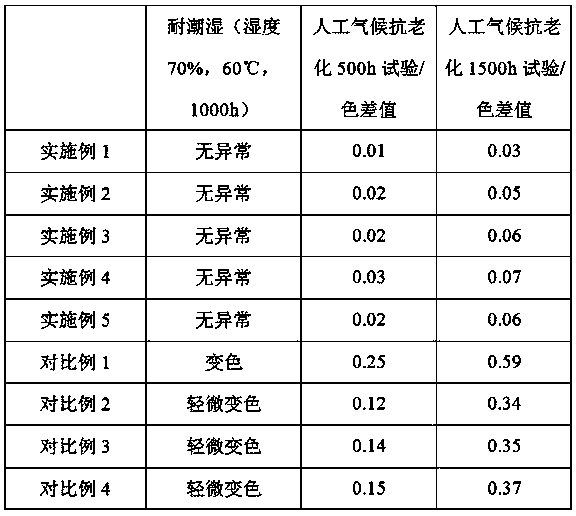

Examples

Embodiment 1

[0026] An antibacterial and sterilization material for coatings, which is made of the following parts by weight of raw materials: 85 parts of modified nano zinc oxide, 0.4 parts of hydroxyethyl cellulose, 1 part of dipotassium glycyrrhizinate, 7 Parts activator, 2 parts chitosan, 1.2 parts polydiallyldimethylammonium chloride, 150 parts deionized water.

[0027] The method for preparing the modified nano-zinc oxide is: adding 6 parts of sodium silicate to 26 parts of water, heating to 70°C, stirring uniformly to form an aqueous sodium silicate solution, cooling to 25°C, adding 10 parts of nano-zinc oxide In the sodium silicate aqueous solution, sonicate for 15 minutes, add 0.7 parts of aluminum sulfate, stir evenly, then add 0.15 parts of isopropyl triisostearoyl titanate and 0.25 parts of isopropanol, heat to 75°C, filter, and reuse Washing with ethanol 3 times, drying, and grinding to 50 mesh to obtain the modified nano zinc oxide.

[0028] The activator is made of the following...

Embodiment 2

[0035] An antibacterial and sterilization material for coatings, which is made of the following parts by weight of raw materials: 80 parts of modified nano zinc oxide, 0.2 parts of thickener, 0.5 parts of dipotassium glycyrrhizinate, 6 parts Activator, 1 part of chitosan, 0.8 part of polydiallyldimethylammonium chloride, 140 parts of deionized water.

[0036] The method for preparing the modified nano-zinc oxide is: adding 6 parts of sodium silicate to 26 parts of water, heating to 70°C, stirring uniformly to form an aqueous sodium silicate solution, cooling to 25°C, adding 10 parts of nano-zinc oxide In the sodium silicate aqueous solution, sonicate for 15 minutes, add 0.7 parts of aluminum sulfate, stir evenly, then add 0.15 parts of isopropyl triisostearoyl titanate and 0.25 parts of isopropanol, heat to 75°C, filter, and reuse Washing with ethanol 3 times, drying, and grinding to 50 mesh to obtain the modified nano zinc oxide.

[0037] The activator is made of the following pa...

Embodiment 3

[0044] An antibacterial and antibacterial material for paint, which is made of the following parts by weight of raw materials: 90 parts of modified nano zinc oxide, 0.6 parts of thickener, 1.5 parts of dipotassium glycyrrhizinate, 8 parts Activator, 3 parts chitosan, 1.5 parts polydiallyldimethylammonium chloride, 160 parts deionized water.

[0045] The method for preparing the modified nano-zinc oxide is: adding 6 parts of sodium silicate to 26 parts of water, heating to 70°C, stirring uniformly to form an aqueous sodium silicate solution, cooling to 25°C, adding 10 parts of nano-zinc oxide In the sodium silicate aqueous solution, ultrasonic treatment for 15min, add 0.7 parts of aluminum sulfate, stir evenly, then add 0.15 parts of isopropyl triisostearoyl titanate, 0.25 parts of isopropanol, heat to 75 ℃, filter, and then use Washing with ethanol for 3 times, drying, and grinding to 50 mesh to obtain the modified nano zinc oxide.

[0046] The activator is made of the following p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com